The issue of organizing heating of industrial facilities is being solved at the design stage. In this case, all possible factors of influence are taken into account - both external and internal. They determine the choice of the optimal scheme, taking into account cost minimization and a positive impact on the production process. What elements do industrial heating systems consist of: boilers, radiators, pumps or other additional equipment?

Industrial heating requirements

When creating a system for maintaining the required temperature in production facilities, current standards are mandatory. Most of them are described in SP 2.2.1.1312-03. According to this document, industrial heating radiators, boilers and other elements of the system are chosen.

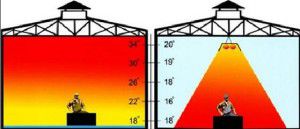

At the first stage, it is necessary to determine the type of heating system. Currently, 2 species are distinguished - zonal and general. The first is intended for the point maintenance of the temperature regime. Most often these are infrared industrial heating systems. They are characterized by economical operation and the possibility of operational regulation of the degree of heating.

If it is necessary to maintain the temperature level throughout the volume of the room, then the best option would be to install a pipe circuit. It can be gas industrial heating, electric or with solid fuel boilers. In addition, when choosing a particular scheme, the following factors are taken into account:

- Features of the production process. In particular, the optimum temperature level and the possibility of its quick regulation;

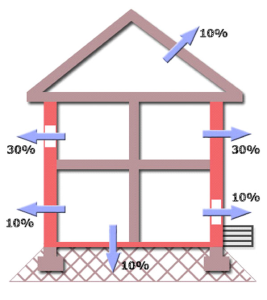

- Building heat loss. It is not always possible to make effective insulation. In this case, it is best to install zone industrial air heating;

- Energy cost. To a greater extent, this refers to the planned production costs, which will ultimately affect the cost of production;

- The cost of equipment, components and labor costs for their installation. According to this parameter, infrared and air heating of industrial premises are the most effective.

To determine the best option, you need to perform a lot of calculations. But there are already well-known "pros" and "cons" characteristic of certain systems.

SP 2.2.1.1312-03 does not give recommendations on the choice of a specific heating system. This regulatory document describes the mandatory requirements for the temperature regime of heating and ventilation.

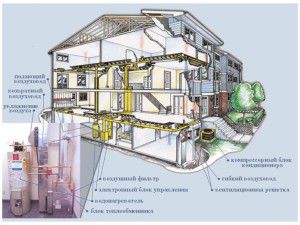

Industrial elements of water heating

This system will be the best option if it is necessary to maintain a comfortable temperature level over the entire or a large area of the production room. It is similar to an autonomous heating circuit with the exception of some nuances. The main one is the large length of the transport line for the coolant and industrial gas heating boilers or their analogues operating on another type of fuel.

There are two types of water heating for an industrial building - autonomous and connection to a heat main. For the latter, an elevator unit is necessarily organized, which reduces the temperature of the coolant and its pressure to normal.

For an autonomous system, industrial heating boilers are used. They differ not only in power, but also in the type of energy carrier used. Also, special attention in the design is given to radiators. The specificity is that for industrial premises with a small (up to 200 m²) and medium (up to 500 m²) area with a ceiling height of up to 3 m, it is necessary to ensure maximum heat transfer. For this, industrial water heating convectors should have a large area.

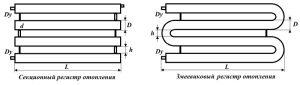

What can replace expensive industrial heating radiators? The best option is the manufacture of registers. They are pipes with a diameter of 50 mm or more, interconnected by jumpers for water circulation.

The operational features of these elements are as follows:

- An increase in the concentration of coolant in a certain part of the system, which leads to an increase in heat transfer;

- The possibility of self-manufacturing;

- The increase in hydrodynamic load, which is offset by the installation of pumping equipment of greater power.

The defining difference between the registers and industrial water heating convectors is the absence of heat exchanger plates. They are designed to better transfer thermal energy from the surface of the radiator pipe to the room. Making them yourself, without the use of special equipment, is very problematic. That is why industrial electric heating boilers are equipped with similar elements.

Factory heating radiators for industrial buildings with heat exchanger plates have greater heat dissipation. But at the same time, their cost is significantly higher than that of heating registers.

Industrial gas heating boilers

One of the differences between industrial models of gas boilers is the type of burner. Structurally, it is a matrix consisting of several sources of thermal energy.

Thus, heating radiators for industrial premises receive a hot coolant with the highest possible temperature. In this regard, the combustion chamber in industrial gas heating boilers is much larger than in domestic ones. This makes it possible to increase the rated power of the equipment.

The fundamental difference in the choice of equipment is the type of gas used:

- Natural gas. To do this, you need to connect to the central highway. Equipment is selected taking into account its characteristics - the amount of incoming gas, its pressure;

- LPG. Actual for creating fully autonomous heating systems for industrial facilities. As a storage place, special containers are used - gas holders. Despite the increased upfront costs, LPG heating has clear financial advantages over similar electric or solid fuels.

For all types of gas equipment, industrial heating batteries can be used. It is important that they correspond to the selected temperature regime.

In most cases, single-circuit boiler models are used to organize gas industrial heating. If it is necessary to make additional hot water supply, indirect heating tanks (heat accumulators) are installed, connected to the main line.

An important point when choosing a gas boiler is the ability to replace the burner. So you can increase its rated power without buying the rest of the components - housing, heat exchanger.

| Model name | power, kWt | Price, rub |

| Euroterm KTN 1.100 SE | 96 | 111000 |

| Protherm Grizzly 100 KLO | 70/99 | 152000 |

| Ross Lux AOGV-96 | 96 | 68725 |

| Fondital Bali RTN E 90 | 90 | 81800 |

Condensing gas boilers have the highest efficiency indicators. But their cost is 45-50% higher than classic ones.

Industrial electric heating boilers

If it is not possible to connect to a gas main or organize a liquefied fuel storage system, the only option is electric heating. Despite the highest financial maintenance costs (energy costs), the installation of industrial electric heating boilers has several advantages. First of all, they include the low inertia of the equipment. Unlike gas counterparts, the heating level of the heating element is adjusted quickly. When installing additional control equipment, changing the degree of heating of the coolant supplied to industrial convectors for water heating will be operational. This will reduce ongoing costs.

In addition to this factor, the following specific aspects of the operation of electric boilers should be taken into account:

- Lack of chimney. This means that the boiler will not be attached to the chimney, like gas or solid fuel analogues;

- Softer requirements for the arrangement of the boiler room. The main condition is a properly made ground loop and selected wiring;

- When installing a multi-tariff meter and heat accumulator you can heat the coolant at nightI when the rates are minimal.

During the preliminary calculation of the heating of an industrial building, it should be borne in mind that the initial cost of an electric boiler will be 20-25% lower than a similar gas boiler.

| Model name | power, kWt | Price, rub |

| Titanium 105/380 | 105 | 42160 |

| Euroterm EK-N 90 | 90 | 35350 |

| Teplomash EKO-1 105 | 105 | 72000 |

| Teplomash EKO1 180 | 180 | 158900 |

One of the determining factors is the availability of pumping equipment and an expansion tank. For models whose power exceeds 130 kW, it is often not part of the design.

When choosing an electric boiler, it is necessary to analyze its maintainability. In particular, a possible replacement of the heating element.

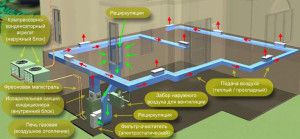

Industrial air heating

Often, engineers are faced with the difficult task of organizing a microclimate in a production room - to make an optimal heating heating system in combination with efficient ventilation. This applies to such industries as chemical, food and woodworking. In this case, the best option is to combine the two systems into one. This will require the installation of industrial air heating.

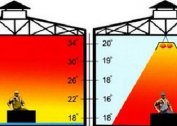

Most often it is made zonal - heating does not occur throughout the entire volume of the room, but only at workplaces. Such a scheme provides several advantages - energy saving, minimizing the cost of arranging the system and using the mains for air conditioning or as hoods.

Unlike industrial heating boilers, the main working element of the air is the climate system, combining several functions. These include the supply of heated air to the consumer and air exchange in the working room.

The following elements will be required for air heating of industrial premises:

- Air heating unit. It can be part of the climate system;

- Channels for transporting heated air. They are made of galvanized or stainless (which is rare) steel;

- Air dampers with guide louvers. Allow to concentrate an air stream on a certain site of a production room;

- Air intake channels for reuse of air masses and their cleaning system. Not a mandatory, but extremely effective supplement. Allows you to reduce costs, especially in winter.

It is noteworthy that the installation of industrial heating of air type does not affect the arrangement of equipment and the general organization of the production process.Unlike heating radiators for industrial premises, it is located in the upper part of the room at a height of 2 meters and above.

When calculating the cost of air heating in industrial buildings, most of the costs are heat pumps. Their main characteristic is volumetric flow. It is also taken into account when calculating the heating system of an industrial building. The average cost of equipment for premises with an area of up to 600 m² is 700-750 thousand rubles.

To reduce heat loss above the doorways, air curtains can be installed.

Industrial infrared heating

An alternative way to organize heating is to install infrared heaters. They generate thermal waves in the IR range, heating not the air, but the surface of objects that fall into the area of their work.

Due to this, when calculating infrared industrial heating systems, you can not take into account the size of the room. It is important to know only the heat loss of the building and to properly distribute the heaters over the working areas. In many ways, this type of heating is similar to air heating of industrial plants and premises. But unlike him, there is one significant difference - there is no need to install pipelines or air channels. This allows you to do zone heating of the room without installing elements similar to industrial convectors for water heating.

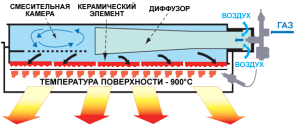

There are two types of infrared heating - electric (film or using carbon fiber heating coils) and gas. Since large amounts of thermal energy are needed for efficient heating, gas models are most often installed in workshops. In this case, the maximum result is achieved.

The following features are characteristic of gas industrial heating:

- The ability to control the power of each device individually;

- The propagation zone of IR radiation depends on the area of the reflector. With its increase, the heating rate decreases;

- It can be used as an option if there is a system with an industrial gas boiler.

However, when designing, it is necessary to take into account the direct dependence of the installation height of the heater on its area of operation. With a significant distance to the object (over 4 meters), IR radiation is scattered. This reduces the efficiency of infrared industrial heating.

Unlike industrial heating radiators, the surface of infrared heaters is heated only in the reflector area. This is the cheapest element in the design that you can replace yourself.

The vast majority of infrared gas heaters operate only on natural gas.

How is the calculation of an industrial heating system

Efficiency, primary and fixed costs for its organization will depend on a correctly performed calculation of heating an industrial building. An important point is the initial choice of the type of heating system - water, air or infrared. Based on this, the optimal set of equipment and components, as well as the method of their installation, is selected.

What to consider when choosing an industrial heating boiler and other system components:

- Heat loss in the building. It is they who will largely determine the planned capacity of the equipment - a boiler, an infrared heater or a thermal curtain;

- The volume of the room and the location of windows and doors. It is important to select the installation location of industrial heating batteries;

- Type of energy. To install industrial electric boilers in a heating system, it is necessary that the power of the input power line corresponds to the parameter of the equipment.

These are just the basic parameters necessary to perform the calculation of the heating system of an industrial building.Important is the type of production and working conditions. Therefore, heating systems are calculated taking into account the operational characteristics of the building and the technology of the production itself.

It must be remembered that all industrial heating systems, including boilers, radiators, pumps must comply with the design parameters. They are determined only after all calculations are completed.

In the video material you can get acquainted with the specifics of heating large rooms.