In the cold season, autonomous heating of the production premises provides the employees with comfortable working conditions. Normalization of the temperature regime also has a beneficial effect on the safety of buildings, machinery and equipment. Heating systems with the unity of the tasks they face have technological differences. Some use hot water boilers for heating industrial premises, while others use compact heaters. Consider the specifics of industrial heating and the effectiveness of various systems.

Requirements for heating industrial premises

At low temperatures, heating of industrial premises, as labor protection requires, should be carried out in cases where the time spent by workers there exceeds 2 hours. The only exceptions are rooms in which a permanent stay of people is not necessary (for example, rarely visited warehouses). Also, the buildings, the inside of which is equivalent to carrying out work outside the buildings, are not heated. However, here it should be provided for the presence of special devices for heating workers.

Labor protection makes a number of sanitary and hygienic requirements for heating industrial premises:

- warming up indoor air to a comfortable temperature;

- the ability to adjust the temperature due to the amount of heat released;

- inadmissibility of air pollution with harmful gases and unpleasant odors (especially for stove heating of industrial premises);

- the desirability of combining the heating process with ventilation;

- fire and explosion safety;

- reliability of the heating system during operation and ease of repair.

During off-hours, the temperature in heated rooms can be reduced, but not lower than +5 ° С. At the same time, industrial heating must have sufficient power to have time to restore normal temperature conditions by the beginning of the work shift.

Calculation of autonomous heating of a production building

When calculating the autonomous heating of a production building, it is based on the general rule that a temperature that is constant without strong changes should be maintained in the workshop, garage or warehouse. For this, a central boiler room is being built, and heating radiators for industrial premises are installed in the working area. However, in some enterprises there is a need to create separate zones with different air temperatures. For the first of these cases, the calculation is made on the use of the central heating system, and for the second - on the use of local heaters.

In practice, the calculation of the heating system of a production room should be based on the following criteria:

- area and height of the heated building;

- heat loss through walls and roofs, windows and doors;

- heat loss in the ventilation system;

- heat consumption for technological needs;

- thermal power of heating units;

- rationality of the use of a particular type of fuel;

- conditions for laying pipelines and ducts.

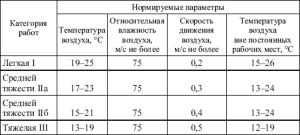

Based on this, the need for heat is determined to maintain the optimum temperature. A more accurate calculation of heating systems for industrial premises is facilitated by the use of special calculation tables. In the absence of data on the thermotechnical properties of the building, the heat consumption has to be determined approximately by the specific characteristics.

When making a choice among various types of production heating systems, one should take into account the specifics of production, heat engineering calculations, the cost and availability of fuel, and build the feasibility studies on this. The most fully correspond to the autonomous heating of modern production facilities are infrared, water, air and electric types.

Infrared heating of industrial premises

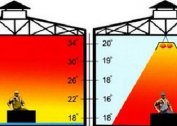

To create the necessary thermal comfort at workplaces, infrared heating of industrial premises is often used. Local infrared (IR) heat emitters are installed mainly in workshops and warehouses with an area of up to 500 m² and with high ceilings. In each of these devices, a heat generator, heater, and heat transfer surface are structurally combined.

Advantages of infrared heating of industrial premises:

- there is only heating of the floor, walls, workshop equipment and directly people working in the room;

- the air does not heat up, which means that the consumption of thermal energy is reduced;

- Dust does not rise in the air, which is especially important for enterprises of the electronic, food industry and precision engineering;

- costs for the design and installation of heating are minimized;

- infrared heaters do not take up useful area.

IR heaters are divided into stationary and portable, and depending on the installation location, on ceiling, wall and floor. If necessary, exposure to individual jobs, apply directional infrared radiation using small wall heaters. But if you mount a film infrared heating on the ceiling of the production room, then the heating will be uniform throughout the area. Often they also arrange underfloor heating based on panels with built-in infrared heaters, but with such a system, energy consumption increases.

The enterprises also find application of infrared gas heating of industrial premises. In such heaters, the fuel is natural gas, which is cheaper than electricity. The main advantage of gas infrared emitters is their efficiency.

Emitters for infrared gas heating systems in industrial premises are available in several types:

- high-intensity (light) with a heat transfer temperature of 800–1200 ° С;

- low-intensity (dark) with a temperature of 100–550 ° С;

- low temperature with a temperature of 25–50 ° С).

A limitation in the use of industrial infrared heaters is the requirement not to place them in rooms with ceiling heights below 4 m.

Water heating for industrial premises

If the company will use a water heating system, for its construction it is necessary to build a special boiler room, lay a piping system and install heating radiators in production rooms. In addition to the main elements, the system also includes means of ensuring operability, such as shut-off valves, manometers, etc. To maintain the water heating system of industrial premises, it is necessary to constantly maintain special personnel.

According to the principle of its device, water heating of industrial premises happens:

- single pipe - regulation of water temperature is impossible here, since all heating radiators for industrial premises are installed in series;

- double pipe - temperature control is permissible and is carried out using thermostats on radiators installed in parallel.

Heat generators for a water heating system are heating boilers. According to the type of fuel consumed, they are: gas, liquid fuel, solid fuel, electric, combined. For the heating of small industrial premises use furnaces with a water circuit.

Choosing the type of boiler is necessary based on the needs and capabilities of a particular enterprise. For example, the ability to connect to the gas main will be an incentive to acquire a gas boiler. In the absence of natural gas, a diesel or improved solid fuel unit is preferred. Electric heating boilers for industrial premises are used quite often, but only in small buildings.

At the height of the heating season, malfunctions or accidents can occur in gas and electricity supply systems, so it is advisable to have an alternative heating unit at the enterprise.

Combined boilers for heating industrial premises are much more expensive, but they are equipped with several types of burners: ggas-wood, gas-diesel, and even gas-diesel-electricity.

Air heating of industrial premises

The air heating system at each specific industrial enterprise can be used as the main, or as auxiliary. In any case, installation in the air heating workshop is cheaper than water, because you do not need to install expensive boilers for heating industrial premises, lay pipelines and mount radiators.

Advantages of the air heating system of the production room:

- saving the area of the working area;

- energy efficient consumption of resources;

- simultaneous heating and air purification;

- uniformity of space heating;

- safety for workers;

- no risk of leaks and freezing of the system.

Air heating of a production room can be:

- central - with a single heating unit and an extensive network of ducts, through which heated air is distributed throughout the workshop;

- local - air heaters (air-heating units, heat guns, air-heat curtains) are located directly in the room.

In a centralized air heating system, a recuperator is used to reduce energy costs, which partially uses the heat of internal air to heat fresh air from the outside. Local systems do not perform recovery, they only warm the internal air, but do not provide an influx of external. Wall-mounted ceiling air-heating units can be used for heating individual workplaces, as well as for drying any materials and surfaces.

Giving preference to air heating of industrial premises, enterprise managers achieve savings due to a significant reduction in capital costs.

Electric heating of industrial premises

When choosing an electric heating method, you should consider two options for heating workshop or storage rooms:

- using electric heating boilers for industrial premises;

- using portable electric heaters.

In some cases, it may be advisable to install small electric furnaces for heating industrial premises with a small area and ceiling height.

Electric boilers have an efficiency of up to 99%, their work is fully automated due to the presence of programmable control. In addition to performing the heating function, the boiler can serve as a source of hot water. Absolute purity of air is provided, since there is no emission of combustion products. However, the many advantages of electric boilers are crossed out by the too high cost of the electricity they consume.

Electric convectors can successfully compete with electric boilers in the field of heating industrial premises. There are electric convectors with natural convection, as well as with forced air supply. The principle of operation of these compact devices is the ability to heat the premises by heat transfer. Air passes through the heating elements, its temperature rises, and then it performs a normal circulation cycle inside the room.

Cons of electric convectors: excessively dry the air, are not recommended for heating rooms with high ceilings.

In a relatively short time, heating radiating panels were able to demonstrate their excellent energy-saving characteristics. Outwardly, they are similar to convectors, but their difference is manifested in the special arrangement of the heating element. The advantage of electric radiating panels is their property to act on objects in the room without heating the air in vain. Automatic temperature controllers help maintain the set temperature.

Whichever of the heating systems of the production premises the owner of the company decides to install, his main task should remain concern for maintaining the health and working capacity of all company personnel.