Inadequate water quality negatively affects human health and equipment. To improve the parameters of the liquid, special devices are used, which must be periodically changed. Self-cleaning filter for cold water ensures the continuity of the water purification process, does not require time for disassembling the device and manual cleaning.

Purpose and scope of self-washing water filters

The purpose of the equipment is to clean the fluid passed through them from dirt in industrial and individual use systems. Depending on the modification, they provide filtering with the removal of particles with a size of 10-15 microns, protecting the trunk from the ingress of rust, grains of sand and other foreign bodies. System Features:

The purpose of the equipment is to clean the fluid passed through them from dirt in industrial and individual use systems. Depending on the modification, they provide filtering with the removal of particles with a size of 10-15 microns, protecting the trunk from the ingress of rust, grains of sand and other foreign bodies. System Features:

- The scope is not limited. The equipment is installed on both metal and plastic pipelines in the direction of flow wherever filtration is required with the possibility of cleaning without disassembling the case.

- Purification of various mechanical impurities makes it possible to increase the quality of the product used for drinking and cooking, as well as extend the life of household appliances and industrial units.

Self-washing filter allows you to restore the operating parameters of the cleaning element, without requiring replacement of cartridges. The design features of some models make it possible to perform self-cleaning without interrupting the operation of the device.

The principle of operation and device

Plumbing equipment is most often installed in poorly accessible places. A clogged filter requires the disposal of a replacement cartridge or the complete disassembly of the apparatus for cleaning it. It is inconvenient and financially expensive. Self-washing designs do not have this drawback.

Plumbing equipment is most often installed in poorly accessible places. A clogged filter requires the disposal of a replacement cartridge or the complete disassembly of the apparatus for cleaning it. It is inconvenient and financially expensive. Self-washing designs do not have this drawback.

The filtering material is: porous disk structures, plastic or metal cellular elements, compacted backfill. Due to the ease of maintenance and high strength characteristics, the first two options are most often used.

According to the principle of action, the equipment is automatic and semi-automatic. The first type does not require external intervention to service. The mechanism starts independently after the operation of the pollution sensor, timer or filling indicator. In semi-automatic devices, the washing process is switched on by a person.

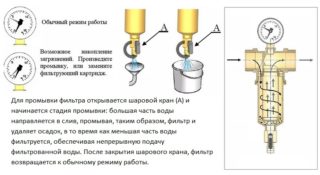

In household appliances, devices are mainly installed, which are a flask with a fine mesh network that can delay a wide range of inclusions. Pollution accumulated on the surface of the filter element gradually clogs the cells and interferes with the passage of liquid. The pressure in the system decreases, the cleaning system is activated. The drain valve opens and the impurities are washed off into the discharge channel or into a special tank under the drain hole.

Varieties of filters

The cleaning process can occur in two ways. In the first case, the action occurs due to the supply of fluid in the opposite direction by a special turbine or air flow from the pneumatic line. In the second, work is performed by means of a tightly pressed stationary scraper. During rotation, the filter element is rotated so that contamination is removed from the surface.

Self-cleaning disc filter It is used for the initial purification of water from the mud fraction in water treatment systems of various industries, water mains and cooling systems. The device consists of a set of high-strength discs tightly pressed against each other located inside the housing with recesses applied to them, the size of which determines the degree of the final product. When the apparatus is operating, liquid passes through the filtration channels, impurities are retained and then removed during washing.

Mesh Devices are used for cleaning from suspensions and therefore are installed in front of reverse osmosis systems, UV treatment and in drinking water treatment systems. There are vertical and horizontal arrangements of aggregates with mesh elements located inside, on which suspended particles are delayed. Self-cleaning system happens: electric - a rubber brush cleans the surface of the element, and the suction scanner removes particles; hydraulic - the action is based on the absorption of contaminants into plastic nozzles.

FMO - an industrial-purpose apparatus with a stainless frame-wire filter element, the parameters of which depend on the performance of the model. Models have an automatic way to remove solids without interrupting the main work process. The design is unevenly divided by a rotary damper, which controls the redirection of the fluid flow to clean the element from contamination. The process is monitored by a local control system with a programmable controller: when turned on, water is supplied to the filter, the air vent opens and the pump turns on, after the air is vented, the outlet valve opens.

Flushing is carried out in stages. Initially, the inside of the mesh is washed, and contaminants enter the drainage collector. Then the outside is cleaned. Further, the internal flap rises perpendicular to the flow and diverts it to flushing the most dirty back. The drain valve is controlled manually or automatically.

- Disk

- Reticulate

- FMO

Criterias of choice

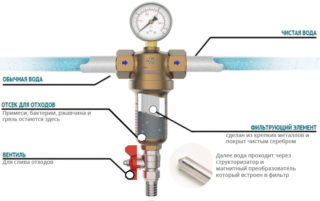

The devices consist of a metal or plastic case with two openings on different sides for connection to the line and external thread, a filter element, a generator, as well as a drainage tap and a case.

Some models are equipped with additional devices: a manometer to control the degree of contamination, a pressure reducer. However, the method for removing dirt from different models may vary and this should be considered when choosing.

- Pressure, water temperature and other parameters of the system to which the apparatus is connected must comply with the technical characteristics of the filtering device.

- For water systems with increased workload, it is better to use devices with automatic and semi-automatic type of service.

- Filtration designs are subdivided according to the size of trapped impurities. Aggregates for fine cleaning stop particles of 20–50 microns, while coarse particles filter inclusions with parameters of 100–500 microns.

- Products with mesh elements lose disk performance in performance, but their maintenance does not cause problems.

Cases of apparatus for filtering hot and cold water differ. Models designed for cleaning high-temperature liquids are made of a stronger material that does not deform when heated.

Installation Features

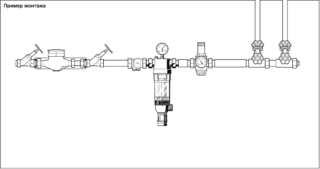

Installation of a self-washing mechanism is recommended after shut-off valves behind a water meter. The installation principle is not complicated.

Installation of a self-washing mechanism is recommended after shut-off valves behind a water meter. The installation principle is not complicated.

- The apparatus is located in an upright position with the bulb down, occupying a small space. The liquid enters through the inlet pipe, the cleaning cells pass, leaving dirt with impurities on them, after which it is supplied to the faucet under pressure.

- At the bottom of the flask is a hole that is closed during normal operation of the filter. If the pressure has become weak, it must be opened. The fluid flow starts to press down and the filter rinses. Then the valve closes again.

- For some models, the design provides for the connection of a drainage hole to the sewage system. If such a possibility is not provided for by the developers, during washing, a container for collecting liquid is installed under the device.

The degree of purification depends on the density of the filter element. The denser the material and the smaller the cell, the better the final result and more often you have to flush the devices.

Advantages and disadvantages of using self-cleaning filters

Like any equipment, these designs have their pros and cons. The positive aspects include:

- minimum time spent on maintenance, plumbing work is carried out very quickly;

- no need to purchase replacement cartridges;

- the possibility of constant use of purified water - the designs of some models provide for a continuous cycle of the filter, it does not need to be turned off even during washing.

The disadvantages include the high cost of the devices, due to a more complex technical process.