The well on the plot allows free access to water, regardless of the availability of centralized networks. However, the rise of water requires the installation of pumping equipment and, as a result, audits with the replacement of worn parts. Therefore, it is important to know how to repair a submersible pump for a well or do it yourself.

The main types and causes of breakdowns

It is impossible to name a critical date after which the device may fail. The technical documentation indicates the life expectancy calculated when used in ideal conditions. In the local network, the need for repair can arise at any time.

- The design of the submersible consists of two nodes: an electric motor and a pump. They are completely interdependent, failure of one can lead to the failure of the other.

- Install the pump in strict accordance with the instructions. Most often, inaccuracies in installation lead to major failures in its operation. The downhole apparatus may not turn on: at a low water level in the well; if there is no current due to cable damage; when fuses blow.

- The engine is characterized by clogging with sand or siltation of the filter plug. As a result, they cease to cool, bearing assemblies fail, and as a result, the rotor wedges. The first sign of this breakdown is the activation of thermal protection immediately after the screw unit is started. In addition, with frequent voltage drops in the network, relays with sensors may fail.

- If the check valve is stuck or the liquid level is low, the machine engine may turn on, but the performance will tend to zero or be completely absent.

- A downhole well pump will not work well if the lift pipe or valves become clogged, the pressure adjustments are incorrect, the pipeline is depressurized, and for a variety of other reasons. The most common is non-compliance with the conditions specified in the instruction manual.

When purchasing a downhole tool, it is worth paying attention to its throughput. Water in the well must have time to accumulate during its operation. Otherwise, sludge, sand and clay pumped by the pump, damaging the impeller of the equipment, will lead to more serious damage.

What kind of work can you do yourself and when do you need help from specialists

During the operation of the device, any unexpected events may occur. Part of the failures requires qualified assistance from specialists. But there are breakdowns that can be dealt with on your own.

During the operation of the device, any unexpected events may occur. Part of the failures requires qualified assistance from specialists. But there are breakdowns that can be dealt with on your own.

- If the engine is running but water does not rise, one of the reasons may be the jamming of the impeller due to its clogging. To start the machine, you need to clean or replace the parts causing the problem. This requires disassembling the well pump. The snap ring retainer is initially removed. Then the shaft is removed and changed from the housing. The assembly process takes place in the reverse order. Before the final start-up, the rotation is checked by briefly turning on the device in the water tank.

- When the tank reaches a certain pressure, the pump must stop. If this does not happen, the automation does not work. For correction, you need to adjust the pressure switch using a pressure gauge or replace this unit.In any case, certain skills cannot be dispensed with, so it is better to contact specialists.

- If the pump stops working, it is necessary to check the presence of voltage at the terminals of the motor sector and, if there is no voltage, replace the wire. In the case of wiring integrity, engine diagnostics at a service center are required.

- A common malfunction is a short circuit in the winding due to liquid entering the motor. Overheating leads to melting of the insulation and contact of the wires. This type of repair is available only in workshops, refers to expensive services and is not always justified.

Before connecting the unit to the system, it is necessary to pump with a sampling to detect sediment. If no suspension is detected, the submersible pump can be started up. Shallow wells represent the greatest danger. In wells over 30 meters, equipment breaks less frequently due to sand.

DIY repair methods

If the pump fails, you must disconnect it from the power supply and remove it from the well to the surface, then carefully examine the body for damage in the form of dents or cracks. Violation of the integrity of the casing indicates the need for its replacement. Operation with a deformed outer shell is not permitted.

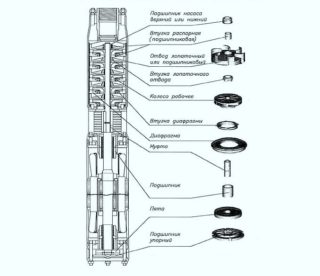

- To establish the cause of the breakdown, you will need to disassemble the device, which is not difficult to perform, having a basic set of tools. The upper and lower parts of the device are separated from each other by unscrewing the fixing bolts. Then all parts are dismantled.

- The blades, shaft, impellers of the lower part are checked for damage and free rotation. If the elements are stuck, they are changed or the device is disposed of. It all depends on the design features of the unit. If nothing is damaged at the bottom, it is collected in the reverse order.

- Before disassembling the upper element, it is necessary to fix the housing in a vertical position so that engine oil does not leak. This type of pump has a single-phase motor with two windings and a built-in capacitor, which become visible immediately after removing the cover. The tester measures the starting and operating resistance. An infinity value indicates an open circuit, and low readings indicate a shorted wire. If the multimeter has not revealed any violations, then you need to change the capacitor.

Assembly after repair is carried out in the reverse order. To facilitate the process before disassembling, you can put marks at the joints and put the fasteners according to the numbering. The water pump is located in a liquid medium. Therefore, it is necessary to check the integrity and the correct location of the gaskets, replace worn elements with new ones.

Preventative measures

Carrying out inspections 1-2 times a year, it is possible to avoid repair of a screw type borehole pump. This process is not complicated and takes a little time.

- The device is removed from the well. A safety cable and an electric cable are examined. If scuffs are found, they are replaced.

- The pump is cleaned and rinsed from the outside, then inspected. Corrosion, deformation, cracks are detected. The presence of a large amount of contaminants on the device indicates the need for cleaning the well.

- The device is lowered into the tank with clean water and turns on. Extraneous sounds indicate a violation of the mechanism and indicate the need for disassembly.

If before that the owner of the device did not repair complex equipment, it is better not to risk it and at this stage transfer the pump to the hands of professionals.

For the water supply to run smoothly, proper operation of the equipment is required. Preventative maintenance helps you diagnose and fix problems in a timely manner.