To equip a bath requires not only good cladding and installation of all necessary items. A very important point is to ensure a favorable microclimate, and for this we need timely, moderate air exchange.

Bath ventilation is a process that must be approached with particular care. If the ventilation system is incorrect, people can get carbon monoxide poisoning or feel bad in the steam room. In addition, a properly equipped ventilation system contributes to more economical fuel consumption, even distribution of air flows, as well as protection of the logs of which the walls of the bath are made from constant dampness, mold and rot.

How to make ventilation in the bath properly

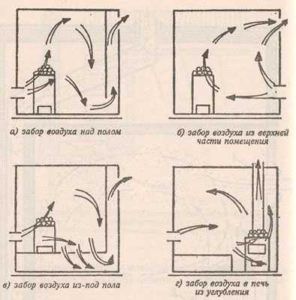

As a rule, ventilation is used in the baths, in which the exhaust air leaves the room through a special exhaust hood, and fresh air enters through the supply opening.

To properly make such a system with your own hands, you need to adhere to the following rules:

- To equip the supply holes, you should choose the lower part of the bath, near the furnace. In this case, the air will heat up faster.

- It is advisable to position the exhaust openings as high as possible - this will help improve traction. If they are too low and the draft is insufficient, then a ventilation pipe is used.

- Supply and exhaust openings should be located opposite each other. In order for the air to be distributed evenly throughout the room, two exhaust openings must be made - one lower, the second higher.

- It is possible to control the supply and exhaust of air by using special dampers that will close and open if necessary.

- The exchange of air in the steam room should be carried out at least 2-3 times in one hour.

Furnace Location

Please note that the ventilation method may depend on the type of bath. For example, in a Russian bath, the ventilation process is often carried out by the usual ventilation method.

Adjacent oven

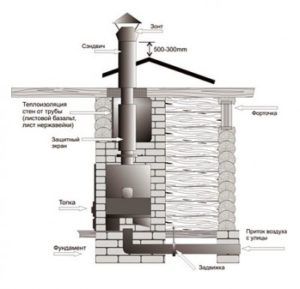

Kamenka furnace in an adjacent room. However, airing does not in all cases give the desired effect. For example, if the stove is not located in the steam room, but in the next room, then the ventilation system must be made as follows:

Kamenka furnace in an adjacent room. However, airing does not in all cases give the desired effect. For example, if the stove is not located in the steam room, but in the next room, then the ventilation system must be made as follows:

- In order for the furnace to last for a long time, the furnace tunnel is bricked up, leaving a gap of 0.5-1 cm.This gap will be required in order to fill it with basalt wool, which will prevent deformation caused by high temperature, and the destruction of the masonry and furnace.

- Then air inlets are made.

- Next, an extractor hood is arranged in the steam room. It is made on the opposite wall and it is desirable that it be located diagonally from the supply openings. At a level of 20-30 cm from the floor, a vertical box is installed, which is brought to the hole near the ceiling and goes outside. The surface of the box is lined with lining or other suitable material.

Air inlets can be made in one of the following ways:

- ventilation duct is held under the floor. Its width should exceed the diameter of the chimney by 120%. A metal sheet is placed near the firebox, which is necessary to protect the floor from fire when coal falls out of the firebox. One end of the ventilation duct is displayed on the street, and the other near the metal sheet. The ends of the channel are closed with metal gratings;

- The difference between the second method and the first is that the ventilation duct is located above the floor. One end is also displayed on the street, and the other to the pre-furnace sheet.

Important! Supply and exhaust openings must have the same area! If you do not adhere to this rule, then the formation of traction that reduces the amount of fresh air.

Steam oven

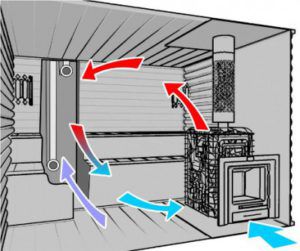

Firebox in the steam room. In this case, the ventilation device in the bath can be implemented in two ways:

- if the stove is in the steam room, then the problem of organizing ventilation disappears by itself. To ensure access to the steam room for fresh air, a gap of about 5 mm is made between the bottom of the door and the floor. Air is discharged through the blower, however, it should be noted that the blower will work only if the fire in the furnace burns constantly;

- in saunas that are not equipped with a chimney, or in saunas in which the oven operates periodically, a more complex ventilation scheme is needed. There are many options for such schemes. For example, you can consider one of the options.

Installation Order:

- A small podium made of bricks is being constructed for the furnace, so that a ventilation duct can be brought to it. The podium is laid out in three rows: the first at the wall, the second in the center and the third at the edge. Then you need to bring the podium to a height of 24 cm from the floor, and lay a brick on top, leaving a hole on which the oven will be installed after.

- Next, you need to lay the end face with a brick.

- The door from the blower is inserted into one end of the ventilation duct, and the second end is displayed in the steam room.

- In the wall adjacent to the steam room and the relaxation room, two canals are being built, which should be located at the level of the brickwork. These channels will close the doors.

- Then you need to install an oven on the podium. To create a uniform load on the box, a metal plate or corners are placed under the stove.

- After that, you need to brick the stove, leaving a gap of 1-2 cm between the brickwork and the stove. Later this gap must be filled with refractory material.

- The last stage is the construction of a brick screen with two convection gate valves.

- For the arrangement of exhaust ventilation, the same scheme is used as for a bath with a stove outside the steam room.

When constructing a bathhouse with your own hands, you need to think in advance how fresh air will enter it and the exhaust air will be removed. If the bathhouse is built of logs, then properly organized ventilation will not only extend the service life of the walls themselves, but also prevent mold and damp smell inside the steam room.