Working conditions in the welding workshop are especially unfavorable for employees. During welding, the air is saturated with oxides of carbon, nitrogen, fluorine, and ozone.

Welding workshop ventilation tasks

-

Using local means (domes, suction, shelters) to pull out the maximum amount of toxic impurities, preventing them from spreading throughout the room;

- Using the general ventilation system of the welding workshop, clean the air of those impurities that have spread further;

- Provide fresh air to reduce the concentration of toxic impurities.

Welding system ventilation system

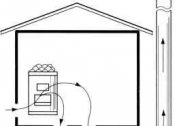

One of the most important points in the organization of ventilation of the welding workshop is the construction of a local lead. The better the fenced place, the less harmful substances will enter the atmosphere of the workshop.

That is, the required exhaust power is reduced. The size and power of the exhaust mechanism is affected by the nature of the welding work. If you mainly cook small parts and do it in the same place, the organization of ventilation of the welding station will be cheaper. About two-thirds of toxic impurities are captured using domes, the rest by a workshop hood. But if during welding it is necessary to move around a large object, local hoods are not effective.

The ventilation of the welding station must be equipped with powerful exhaust systems, 30% of the power must be directed to the upper tier of the workshop, and 70% to the lower.

Calculation of ventilation of the welding shop

The calculation of ventilation in the welding industry is based on the number of electrodes used per hour. So, when welding manually, one kilogram of electrodes accounts for from 1.5 to 4.5 thousand cubic meters of air per hour. If welding is carried out by a semi-automatic method in carbon dioxide, from 1.7 to 2 cubic meters of air per hour are laid per kilogram of electrodes. On average, one worker uses about five kilograms of electrodes per hour.

For ventilation of the welding production, it is necessary to take powerful fans, they are installed outside the building on special supports. Ventilation ducts are mounted from metal pipes in places accessible for installation and closest to the workplace.

When installing the ventilation of the welding section, it is important to arrange the supply pipes so that they capture the location of the workers and at the same time facilitate the function of the outflow of contaminated air.

In some cases, a filter is equipped on the exhaust part of the ventilation of the welding section. This allows you to create air recirculation in the workshop, without throwing harmful impurities into the atmosphere of the city.