The ventilation of the steam room is the most important component of the design of a modern bath. Ventilation is used to remove excess steam, exhaust air and proper heat distribution in the room. It is possible to provide ventilation in the steam room with your own hands, having invested quite a bit of funds and materials. But first, let's figure out whether ventilation is needed in the steam room.

Why in the steam room ventilation

Properly constructed ventilation in the steam room solves two problems:

- comfort for soaring;

- safety.

The lack of air exchange or illiterate ventilation made in the steam room can lead to such sad consequences as:

- rapid decay and wear of the structure. Even in a properly constructed bathhouse, wood lasts no longer than 2 decades. If there is no ventilation, this period will be reduced by several times;

- the unpleasant smell of rot and mustiness will discourage visiting the steam room;

- the accumulation of gases and germs is harmful to health. During the burning of firewood and being in the bathhouse of people, gases are released. And in a humid and warm atmosphere, mold, fungi develop. If there is no air exchange, all harmful impurities are concentrated, making bath procedures dangerous for the human body.

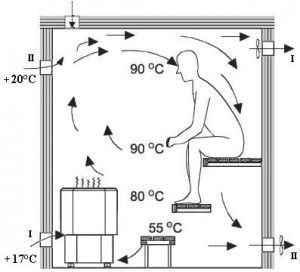

One of the most important ventilation functions in the steam room is the optimization of heating. Water saturated with water vapor, weak heat conductor.

That is why a bath without ventilation is heated longer. To enhance the movement of air, the inlet opening is located behind the firebox, just above the floor. The air entering the room first warms up without lowering the overall temperature in the steam room.

So, ventilation in the Russian steam room is needed, but how to do it right - read on and watch the video.

The rules of the ventilation device in the steam room

There are many ventilation schemes in the steam room. Choosing the right one depends on the architectural features of the bath. But some laws cannot be violated in any case.

- The air flow is organized in the lower part of the room, preferably near the firebox;

- The outflow of exhaust air during the construction of ventilation in the steam room with your own hands is best placed on the opposite side, as close to the ceiling as possible. Some owners make an exhaust hole directly in the ceiling, which has its pros and cons.

You can not place the inflow and blowing at the same height!

Otherwise, most of the air in the bath will not participate in the movement. Your legs will freeze and your head will overheat.

The diameter of the ventilation holes depends on the volume of the bath:

1 square meter of air requires 24 square meters. centimeter diameter pipe.

Before arranging ventilation in the steam room, it is necessary to consider the system of valves. They are needed to regulate the air flow and allow you to quickly cool or warm the bath. It is advisable to install ventilation pipes during the construction phase of the building.

Signs of poor ventilation:

- condensation on the walls;

- mold in the corners;

- heavy odor;

- drafts;

- cold in the middle and upper layers of the air;

- the bath does not gain temperature well and quickly cools down;

- fresh supply air is removed, and carbon dioxide remains in the room (sensation of stuffiness).

Even in a very hot melted steam room should breathe easily.

Which ventilation is better: natural or forced?

Thinking about how to make ventilation in the steam room, you need to solve the main question: air exchange will be natural or mechanical. Both methods have advantages and disadvantages.With your own hands equipping ventilation in the steam room, it is easier to resort to mechanical traction.

There is no need to carefully verify the location and diameter of the ventilation ducts, mastering the skills of the stove-maker. You just need to insert the fans - and they themselves will do all the work.

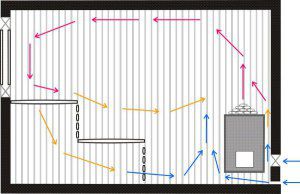

- With the natural ventilation scheme of the steam room, the movement of air is ensured by the difference in temperature and pressure outside and in the bath. Warm air rushes to the ceiling, stretches out into the street, creating some discharge of air. The lack of pressure is compensated by the influx of fresh air. Natural ventilation is especially good in steam rooms made of wood - a breathable material. The movement of air flow is supported by the presence of gaps between the logs. If the area of the bathhouse is small, natural air exchange will be quite enough;

- With a forced ventilation scheme, the flow or blowing of air in the steam room is organized by a fan. Sometimes fans are installed on both the inflow and outflow. In such cases, ventilation grilles can be mounted anywhere. If there is only one fan, the air flow is made only near the floor behind the firebox. A large bath built of stone or brick cannot be properly ventilated in a natural way. Auxiliary methods for improving traction are used, for example, an exhaust fan or a supply valve.

The advantage of the natural scheme of ventilation steam rooms in low cost. However, it is not always possible to install exhaust pipes in the right places and you have to resort to mechanical traction.

Before you make ventilation in the steam room, you must purchase a fan. Not every model will cope with high humidity and temperature. An ordinary household fan can only be used to ventilate the room at the end of the bathing procedures.

In addition to fans, traction amplifiers also include deflectors. They are placed on the outer end of the ventilation duct.

If a gas column is installed in the steam room for heating, a special ventilation duct is equipped for it.

Often, steam rooms and saunas are equipped with supply and exhaust systems that independently regulate the temperature, humidity and air exchange in the room.

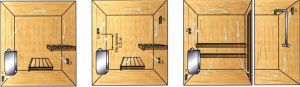

Steam room ventilation schemes

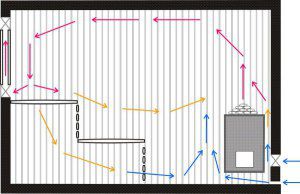

A steam room ventilation device error can be expensive. How to properly position the ventilation holes clearly show the scheme:

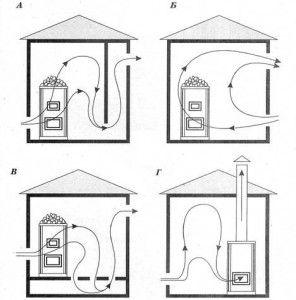

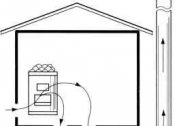

AND - Photo of the ventilation of the steam room with natural draft. The inflow is organized behind the furnace, the outflow is opposite from the top of the room. To make the system work in windy weather, the exhaust pipe is made vertical, its edge is higher than the roof ridge. It is important to choose the correct diameter of the air ducts, then the air exchange will proceed on its own. It is regulated by dampers.

B - in this photo ventilation is done in the steam room with an uncharacteristic distribution of air ducts. The scheme is used when only one wall can be allocated for ventilation. Air enters the steam room from below, enters a hot stove, warms up and rushes to the ceiling, gradually moving to the exhaust outlet. The hood is necessarily forced.

AT - not only the steam room is ventilated, but also the underground floor, preventing rotting of the boards. The supply air is immediately warmed by the stove, goes down through the floor slots, then rises and extends into the street.

G - in this photo the chimney is used to ventilate the steam room and is an exhaust hood. Supply opening opposite the stove near the floor. Such ventilation is more often arranged in public steam rooms, since the furnace works constantly here.

A very important role in organizing the ventilation of the steam room is played by the oven. It is on its location that the ventilation scheme largely depends. A more efficient air exchange is possible when the heater is installed directly inside the steam room, and not in the adjacent room.

About airing the Russian bath

In a classic Russian bath, it is impossible to install a mechanical hood. In a matter of minutes, she will blow all the steam outside. Therefore, after the end of the bathing procedures, the room is simply thoroughly aired. To do this, most often open the door and window, which is usually located on the wall opposite from the door. If there is a forced range hood, it can be used, but also with the door open. It is imperative to remove all the wet leaves from the brooms, because they retain moisture and germs. And benches and wooden floors are dried with towels. In wet boards of the germs, microbes remarkably multiply and harmful substances accumulate with sweat accumulate.

Having thoroughly dried and ventilated the room, you can begin to heat the steam room, where ventilation is necessary.

During heating in the steam room, the exhaust pipes are closed and the inflow is opened.

As soon as the temperature in the steam room reaches the desired value, the valve of the lower exhaust pipe opens, the inflow is left as it was. Thus we make the air move in a circle. A hot air cushion remains in the upper part of the room, providing uniform mixing.

To make ventilation in the steam room, as a rule, you can do it yourself with minimal funds. To do this, you only need to understand the principles of air flow.

To avoid mistakes in the organization of ventilation of the steam room, watch the video: