All woodworking enterprises have one common problem - the formation of chips, dust and sawdust, which not only pollute the air in the workshops, but also, if piled up, can cause a fire. Therefore, safety regulations for such enterprises provide for the regular cleaning of workshops and workplaces from technological wood waste.

The removal of wood is carried out using suction systems, which are installations that suck wood dust and sawdust, and move them to special bins. As a rule, such bunkers are located outside the workshop, in places that make it possible to conveniently unload and export accumulated sawdust.

Classification of suction systems

All suction systems used in enterprises that specify the processing of wood are classified according to the following criteria:

- air circulation method;

- type of hydraulic mode used in the installation;

- type of connection of the dust extraction unit with technological equipment.

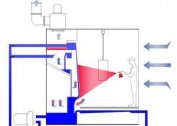

The method of air circulation. Aspiration units can be direct-flow or recirculation. The principle of direct-flow systems is based on the intake of air from the premises, its purification and subsequent release into the atmosphere.

Recirculation equipment also purifies the air from pollution, however, it does not throw it outside after cleaning, but returns it back to the workshop. Such systems contribute to a significant reduction in heat loss in the cold season and a decrease in the cost of money for heating.

Type of hydraulic mode. According to this criterion, all suction systems are divided into two types: working in a constant mode and working in a variable mode.

Type of connection of the dust extraction unit with the equipment. Distinguish between autonomous and centralized cleaning systems. The latter are connected to several working woodworking plants, each of which, if necessary, can be turned off or on.

Autonomous systems are connected to one or more woodworking plants that turn on and off at the same time.

Operating principle

Aspiration systems consist of several main parts:

- Bunker.

- Cyclone.

- Industrial fan.

- Pipelines branching across the workshop’s work area.

Thanks to the ventilation system, a vacuum is generated in the dust extraction system, under the influence of which dust and waste are transferred from the workplace to the separator. In the separator, large particles are separated, which enter the press, are formed into briquettes and sent to a separate warehouse. Air with residues of fine fractions and dust is filtered by several bag filters, and then the cleaned air flows are sent either to the street or to the workshop. The dust that accumulates in the filters is collected in special containers or also briquetted.

Types of suction systems

When choosing dust collecting equipment, the following data should first be taken into account:

- The duration of the machines.

- Number and diameter of suction devices.

- Air velocity in the dust collecting unit.

- Number and size of chips to be removed.

- The size of the bin in which the waste is stored.

- The presence of suction devices that can be moved around the workshop.

PUA, PUAK waste disposal devices

Using the PUA and PUAK systems, dry, non-sticky chips and dust are removed.Since these systems have a low pressure, they should be installed at a distance not exceeding three meters from the machine. The performance indicators of such units range from 1250-3900 m³ in one hour. In these devices there are no mechanisms that regenerate filter surfaces. PUA systems require regular removal and cleaning of accumulated dust from the filter bag, and the frequency of such cleanings depends on the fraction of particles - the finer they are, the more often you have to shake them out.

To work with very fine dust, PUAK units are most often used, which are instead of a filter sleeve equipped with pleated filters. These devices are characterized by greater performance compared to PUA.

For the regeneration of the filter elements using compressed air. PUA and PUAK are used in small enterprises with intermittent loading of machines. Depending on the model, the units can be equipped with manifolds and hoses designed to connect several suction pumps to one machine. In continuously operating enterprises, these installations are not recommended.

Compact filters (bag)

Such devices remove any dry dust that is not prone to sticking. The most common models include RFU-10, RFU-5, RFU-3,5. A standard apparatus consists of a fan enclosed in a soundproofing casing, a silencer, a filtration section, a mechanical regenerative mechanism, a dust collection bin and a control system, which is a metal cabinet. The dust collecting bin is equipped with wheels and a device that allows the elevator to grab it and tip it. The waste absorption process is carried out thanks to a ventilation system that creates a vacuum.

The performance of small-sized hoses is 3500-10000 m³ per hour. The distance at which the devices should be installed from the machines is no more than 15 meters. It is possible to change the fan speed and, accordingly, the pressure. This aspiration for woodworking with a tight production schedule, which does not form a large amount of waste.

Filters for large systems

The performance of filters used in central aspiration systems is 8000-20000 m³ per hour. Mostly these are bag filters with internal or external type of execution.

Such systems consist of a filter section, a fan enclosed in a noise-insulating casing, a regenerative mechanism, a waste collection bin and a cabinet with a control drive. In addition, these systems are equipped with a support frame and a pipe that connects the filter to the fan. The capacity of dust collecting bins is from 1 to 3 m³.

The most common bag filter models for large systems are SRF8 and SRF15. The sleeves in them are made of special needle-punched material, along which dust blown away by compressed air easily moves into the storage hopper. Central aspiration systems are especially relevant for large enterprises that produce dust with low weight and significant volume.

Aspiration for woodworking allows not only to clean the air, the territory of the workshop and prevent the occurrence of fire, but also to use the collected sawdust for secondary production, which significantly increases the efficiency of the woodworking industry.