Work in the spray booth is significantly complicated by a suspension of chemicals, including the smallest particles of paint. They are harmful to the paintwork staff and degrade the quality of work. Therefore, it is necessary to equip the ventilation system of the spray booth. Effective operation is possible only after careful calculation of the ventilation of the spray booth. The calculations are very important, since the accumulation of harmful fumes can cause poisoning, fire and explosion.

Calculation of ventilation of the paint shop

As a rule, the ventilation project is based on the area of the room. When calculating the ventilation of the spray booth, the size of the object to be painted must also be taken into account. It can be a couple of doors of a passenger car or a whole body. That's why you need an accurate calculation. When painting small-sized parts, the air in the room should change 5 times per hour (if painting is carried out without sprayers).

As a rule, the ventilation project is based on the area of the room. When calculating the ventilation of the spray booth, the size of the object to be painted must also be taken into account. It can be a couple of doors of a passenger car or a whole body. That's why you need an accurate calculation. When painting small-sized parts, the air in the room should change 5 times per hour (if painting is carried out without sprayers).

If large parts are painted with a spray gun, air exchange should be carried out 20-100 times in one hour.

In this way:

- The ventilation system of the spray booth is quite expensive for owners of large workshops;

- At the same time, ventilation ensures the health of workers and reduces the likelihood of accidents (fires) in the workshop;

- Large paint shops are almost completely automated, which further increases the percentage of air pollution.

DIY spray booth

If the dimensions of the workshop are approximately 4 by 6 meters (the size of a standard garage), you can equip the ventilation of the spray booth with your own hands. However, the worker should only paint in a respirator and protective suit.

The supply and exhaust ventilation scheme of the spray booth is used. The intensity of the inflow should exceed the intensity of the outflow.

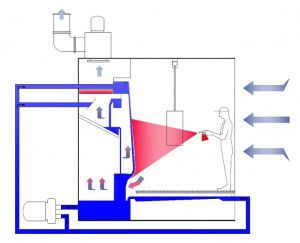

Most chemicals used in such workshops are explosive. Therefore, explosion proof check valves must be installed on ventilation shafts. Also, the ventilation scheme of the spray booth depends on the type of reagents used in the workshop:

- If reagent pairs are lighter than atmospheric air, it is necessary to organize the outflow of 70% of air from the upper part of the room and 30% from the lower;

- If they are heavier, 70% should be pulled from the bottom and 30% from the top.

When using DIY ventilation equipment, special hoods should be installed above:

- Tables and racks for painting;

- Baths for painting (they immerse parts and accessories);

- Devices for blasting;

- Systems for degreasing parts.