Local ventilation is a type of system in which the air mixture is supplied to a certain point in the room - fresh air ventilation, or the outlet of the contaminated air mixture from the place of formation of harmful emissions - an exhaust type action system.

The supply type system delivers pre-cleaned and heated air, the exhaust system removes the air mixture from a certain place in the room where the highest concentration of harmful particles in the air is observed.

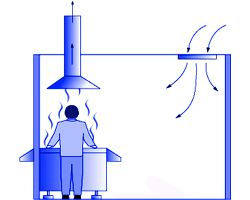

The simplest example of local ventilation is a conventional cooker hood, which removes air from the space above the stove. Most often, such ventilation systems are used in industrial premises, but in residential buildings it is not so rare.

Where local ventilation is required

The system that carries out the used air must be installed in any home. In particular, its presence is required in those rooms inside which various odors, smoke, gases, dust particles and other things accumulate. For example, it is important for owners of private houses where there is a built-in garage to take care of the availability of a functional and efficient duct system, with which a device is installed that provides forced air exhaust. If this is not taken care of, the exhaust gases will penetrate into the residential part of the room and through the doors, and even through the walls of the room.

Local ventilation should also be in the kitchen, as in any room of this type various smells always accumulate. Although many of them are quite pleasant, their constant presence is completely out of place. That is why local ventilation in this part of the house is an important condition for the comfort of the kitchen.

Another room in the house that needs a high-quality ventilation system is a bathroom. Without an air outlet, the walls of this room, together with the ceiling, will soon be covered with mold.

Do not also forget about such a part of the house as the bathroom. The air exchange there is required multiple, especially if it is separated from the bathroom and has a very limited space.

What is local ventilation?

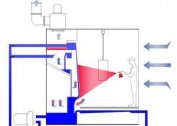

Local ventilation, working with the hood - a type of device that provides a quick outlet of used air and any contaminants directly from the place of their occurrence. Such devices are indispensable when the part of the room where harmful particles appear is localized, it is necessary to prevent their spread to the rest of the room.

Local ventilation of this type makes it possible to capture and quickly remove certain types of emissions - smoke, dust, gases, excess heat generated during the operation of certain equipment. The functioning of ventilation of this kind ensures a good effect, it protects the respiratory system of all those inside. At the same time, the volume of the air mixture discharged by the system is very small.

Types of local ventilation systems

Local ventilation, used today in rooms for various purposes, is quite diverse. This is explained by the tasks that are put forward to the system, as well as some features of its functioning.

This type of ventilation system is divided into categories according to some criteria:

- exhaust and supply type - depending on the purpose;

- depending on the coverage area - local and general exchange type;

- the method of carrying out the withdrawal of the air mixture is natural or mechanical;

- design features - channelless and channel.

Ventilation characteristics

The effectiveness of natural ventilation is determined by the wind speed outside, as well as the temperature. As a consequence of this, such a system is not always able to provide an appropriate level of air exchange.

Therefore, where there is a need to quickly remove a certain amount of air mixture, and in its place serve as much fresh, local ventilation with a mechanical type of work is often used. When using such a device, fresh air of a given humidity and temperature, completely meeting the necessary standards and requirements, is brought to the right place.

Exhaust ventilation removes poor-quality air even over long distances, before it enters the atmosphere, the mixture can be cleaned.

If there is a need, the supply and exhaust systems in automatic mode turn on and off at the set time, which made their use in production very convenient.

Mechanical air purification systems for transmitting it over distances are equipped with some important components:

- fans and electric motors, which ensure the transfer of the mixture;

- heaters and dust traps for carrying out the required treatment of the mixture;

As a result of these properties, exhaust devices imply a fairly high energy cost. But such systems quickly remove and supply the air mixture to local areas in any conditions. If necessary, the air mixture lends itself to some types of additional processing - increasing humidity, cooling or heating, cleaning.

Local exhaust system

Local ventilation, which ensures the removal of a contaminated air mixture, is most effective when the place where any contaminants are released is completely localized. In this case, it is usually required to prevent the further spread of the contaminated air mixture throughout the rest of the space.

An exhaust system of local air purification is often used in production, where it effectively and efficiently removes all kinds of harmful particles from the air: smoke, gases, ordinary dust, as well as heat from working devices. In order to remove such substances, local suction is used - varieties of shelter that can be in the form of covers for a particular technique, umbrellas, cabinets, and the like.

The main requirements put forward for such equipment are the following:

- the place in which the discharge forms, maximally covered;

- the local suction has a well-thought-out design, so that its use does not interfere with the operation of the equipment;

- all contaminants from the place of their isolation should be removed in the same direction in which their natural movement occurs: high temperature vapors - up, dust - down;

- Before venting the spent mixture to the atmosphere, local ventilation must clean the mixture.

The most complex exhaust equipment is considered to be one that provides an increased degree of purification of exhaust air from dust and all other contaminants.

Local ventilation of this variety is highly effective, since it ensures the removal of harmful substances directly from the places of their isolation and formation, preventing them from spreading throughout the entire space of the room. Since most of the harmful substances that are released into the air mixture differ in significant concentration, with a relatively small amount of air discharged, a good hygienic effect is achieved.

However, it should be noted that such systems are far from always able to qualitatively solve their problems.

So it will be, for example, if the pollution is distributed over a large volume of space, if the supply of fresh air mixture to separate zones does not provide the required air parameters, if work involving the release of substances polluting the air mixture is carried out simultaneously on a large territory.

Varieties of local suction

One of the main varieties of this type of exhaust device is local suction. At the moment, there are several types of similar equipment.

Half open suction - most often fume hoods are used as such equipment, sometimes ventilated chambers.

Such devices can provide the fastest and most effective removal of small particles from the air at its low consumption. There are several types of such suction. To remove substances from the air at high humidity, as well as with high temperature, equipment with a hood located in the upper part of the device is used. Cabinets equipped with a lower fence of the air mixture are used to withdraw the “heavy” air mixture. Portable devices, where the intake of the air mixture is carried out from the outside, are mainly used to remove dusty types of pollution.

Open devices - an exhaust structure located behind the source of pollution. At the moment, the most common devices of this category are side suction and exhaust type umbrellas.

A lateral air intake device is used when it is required to have access to the source of emission of pollutants from all sides. Hood umbrellas are one of the simplest types of such equipment. They are installed in places where the released pollution is independently understood upward. The good efficiency of this type of equipment is achieved due to the significant volumes of the removed air mixture.

The closed air intake looks like a large cover, where there are special openings, through them air enters the equipment along with pollutants.

Based on the foregoing, it is safe to say that local exhaust ventilation is an excellent way to quickly and efficiently remove contaminated air from a localized place, preventing its spread to the rest of the room. In this case, the removed air is replaced by the same amount of fresh air.

Due to its characteristics, this type of air purification system is intended primarily for use in production, but sometimes such ventilation can also be found in residential premises.