Effective ventilation is necessary in both office and utility rooms. Sometimes it can be organized independently, such as in the case of a spray booth. Garbage collection ventilation is designed and built by professionals.

Spray booth ventilation

The spray booth is a separate room with equipment for painting metal parts. During operation, the smallest drops of paints (spray mist) and solvents are released into the air. To ensure the safety of personnel, there must be ventilation in the spray booth.

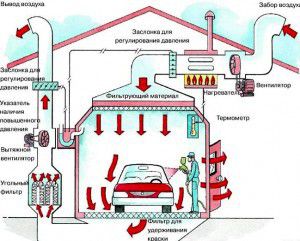

In the paintwork, a supply and exhaust ventilation system is organized, reinforced by an additional exhaust hood in the lower part of the room.

It is convenient to organize the lower air outlet by raising the trellised floor 15-20 cm above the main level. Under the grill, air intakes with filters are installed.

The calculation of ventilation in the spray booth is quite complicated, since too much air movement can disrupt the process. Insufficient endangers the health of personnel. Air flows when calculating the supply and exhaust ventilation of the spray booth are calculated by a professional. It is mandatory to filter outgoing air.

The ventilation of the spray booth performs the following tasks:

- outflow of exhaust air from the room;

- supply to the room of clean street air with a temperature of no higher than 25 degrees;

- discharge of purified exhaust air into the street.

Supply street air is pre-cleaned by dust. At the same time, the exhaust air is filtered from particles of chemicals with special paint filters.

The air exchange rate in the chamber can reach 200 times!

Types of ventilation systems in paint

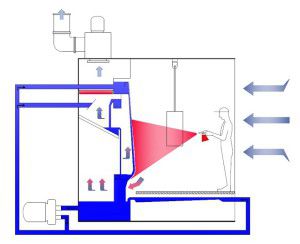

For the spray booth, it is possible to calculate and organize the supply and exhaust, twin-engine or single-engine ventilation system.

With a single-engine ventilation chamber, air is supplied from above, providing deposition of the spray mist down to the exhaust nozzles.

The twin-engine ventilation spray booth is equipped with an additional motor that removes exhaust air from the work area to the outside. This is a more efficient system, however, its installation is not always economically justified. So, in spray booths with a low turnover, it is more expedient to equip one-engine ventilation with their own hands.

Supply and exhaust ventilation operates in 3 modes:

- Intensive air movement with filtration;

- Air inflow from the street with filtration, bringing the temperature to 30 degrees and outflow through nozzles in the floor. This mode provides constant climatic conditions;

- Supply of cleaned and warmed up to 60 degrees air to dry painted parts.

When calculating the supply and exhaust ventilation of the spray booth, it is necessary to avoid “dead zones”, where air stagnates along with all harmful impurities.

The most common option for spraying is increased pressure when two fans are operating: supply and exhaust. The blowing fan is more powerful, due to which increased pressure is provided. At the same time, dust is forced out of the room, not sucked out. To create a vacuum, the power of the exhaust fan is higher than the supply air.

In a chamber with circulating air flow, tightness should be ensured. Since air moves due to the operation of two fans and the pressure inside is equal to the pressure outside.

Multiplicity of air exchange in the spray booth

High-quality and safe operation of the spray booth is guaranteed only with proper calculation of ventilation. Proper air exchange will provide excellent coloring results, staff health and prevent fires or explosions.

The difficulty in calculating the ventilation of the spray booth is that the size of the part to be painted must be taken into account.

For example, when working with a small area, air exchange should be five times. If the body of a passenger car is painted, the ratio rises to 40 - 100. Thus, in large workshops it is disadvantageous to paint small parts. Moreover, the more intensive the air exchange, the less the load on the human body. Therefore, in order to reduce the risk for people, paint machines automate as much as possible.

The standard ventilation scheme of the spray booth combines the flow of air into the spray booth, its removal to the street and air recirculation. 2 fans of the calculated power move air. The main task in calculating the ventilation of the spray booth is the selection of fan parameters depending on the required air exchange.

On average, the spray booth has a capacity of about 20,000 cubic meters of air per hour. It provides excellent workpiece quality and safety for personnel.

To calculate the air flow for the chamber, it is necessary to multiply the rate of air exchange by the volume of the chamber.

To calculate the supply and exhaust ventilation of the spray booth, you need to know the pressure and performance of the fans. The magnitude of the pressure drop depends on the area of the filters: supply - from the ceiling, and exhaust from the floor.

Fan performance is selected according to the tables provided in the instructions for the fan.

Floor spray booth

One of the most important components of the ventilation system of the spray booth is the floor. Outflow of exhaust air occurs through trenches in the floor, covered with grilles or the floor is raised by a 20 cm ramp. Filters and exhaust pipes are installed in the resulting space.

For organizing a ventilated floor, it is convenient to use a finished metal hole floor.

The nozzles of the exhaust pipes are distributed so that there is no unreached space where air can stagnate. In addition, it is necessary to provide for the replacement or cleaning of filters.

DIY ventilation

If the paint room is constructed independently, the installation of ventilation elements begins after wall cladding and lighting.

First, an exhaust hood is installed in the floor, made of exhaust fans. From heaters and fans under the ceiling, a heat gun is built for air intake. From here, air flows through the pipes to the center of the room. You can install a nichrome wire as a heating coil.

Tena is safer than heat generators using liquid fuel.

Heating ten need 6 or 8, they are a conductive thread hidden in a metal tube. The tubes are filled with an insulating, heat-conducting material. A nichrome thread transfers the required specific power to the surface.

Security

For safe operation of the ventilation system of the spray booth, three methods are used:

- explosion proof check valves on ventilation ducts;

- monitoring impurities in the air chamber;

- additional exhaust nozzles near the main sources of pollution.

For example, when substances are released during staining lighter than air, 30% of the air is removed from the lower tier, and 70% from the ceiling. If the impurities are heavier than air, they quickly settle.Therefore, assigned to the bottom. Explosion-proof bends are required above paint racks, bathtubs, and jet installations.

Having carefully calculated, you can equip high-quality ventilation of the spray booth with your own hands, saving on the services of expensive specialists.

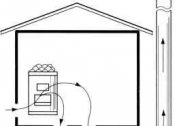

Waste chamber ventilation

The garbage collection chamber is equipped with natural (sometimes forced) ventilation, which ensures compliance with sanitary standards. As an air duct, the trunk of the garbage chute is used. And the ventilation unit of the garbage collection chamber is located above the trunk of the garbage chute.

The ventilation system of the waste collection chamber consists of the following elements:

- ventilation duct;

- a gate blocking the duct during cleaning and disinfection of the trunk of the garbage chute;

- exhaust fan or deflector;

- sealing rings for vent duct output through the roof.

The ventilation duct is installed vertically, in the center of the trunk of the garbage chute. Standard channel diameter 300 mm. If necessary, the deviation of the channel is allowed no more than 30 degrees to the vertical.

The duct sections are attached to each other by metal adapters.

The inner walls are smooth and non-flammable. It is necessary to insulate a section of the channel passing through the unheated attic. The passage of the duct through the roof is sealed with a metal apron and sleeve.

To prevent back draft in the ventilation of the chute, another duct is installed in parallel with it, which is connected to the main one at the top. The connection can be closed with an automatic or manual shutter.

In modern high-rise complexes, garbage chambers are tight, and the barrel of the chute is equipped with a sink. Natural draft in summer almost does not function in it, therefore cameras are equipped with forced exhaust ventilation.