In a private house, especially built using modern technology, quality ventilation is required. Buildings constructed with the help of so-called SIP panels have a strict requirement, which consists in the installation of a mandatory supply and exhaust air circulation system. Also, a good extractor fan and ventilation in a private house are necessary when it is built of wood, brick or cast from concrete.

The basic rules for the formation of air flow patterns inside the house

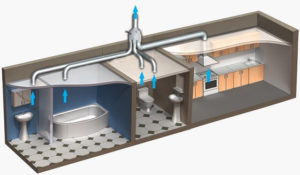

A hood in a private house is organized on the basis of one simple principle. Air must be taken in from outside, passed through living rooms and discharged in the kitchen or in other technical rooms. In this case, the amount of heat should be balanced. For example, if there is an extractor hood in the kitchen designed to divert steam and odors from cooking into the ventilation, its flow should be taken into account when calculating the circulation scheme of the whole house.

Another important rule that must be observed when you need to install the hood in a private house is that all channels must pass through the main walls inside the house. This is a key requirement, since when the channel freezes, the effect of the reverse movement of the air flow may occur when the air outside with the natural ventilation method begins to enter the premises.

Prefabricated house ventilation

Structures built by the panel method of housing construction have their own characteristics. A short list is as follows:

- all walls, except for interior partitions, are an impenetrable zone assembled from separate elements;

- ventilation channels are best done inside the interior wall, through which you can either lay pipes if the structure is made of drywall or similar materials, and form passages of brick;

- the ventilation structure can be done with your own hands if the internal layout is created after the commissioning of the facility;

- a permanent element that is always the right thing to do in prefabricated houses is the exhaust duct block, which is displayed at least a meter above the surface of a flat roof or half a meter above the ridge of a gable roof structure.

Ventilation in prefabricated houses is only natural. However, this does not mean that the hood in the kitchen or blowers cannot increase the flow of air that passes through the provided ventilation ducts.

Ventilation systems in a wooden house

Many developers claim that since the house is breathing, it is possible not to install forced circulation systems, but to manage naturally. This is far from the case.

In fact, the breath of the walls in a wooden house is a myth. The processed material simply absorbs and gives off moisture. However, air circulation through the tree practically does not occur. If it is not correct to extract air in a wooden house, its service life will be significantly reduced, and the condition of the logs will constantly deteriorate. Despite the use of various impregnations, it is even possible to spread rot and mold in every major wooden construct.

Hoods and ventilation points in a wooden house are made quite simple. In this case, radically different principles are applied, each of which shows the best results in cold or warm climatic zones.

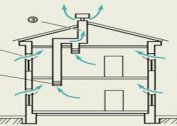

- The air in a wooden house is forcibly forced, and is removed naturally. Such a scheme is best done in a warm climate, since the amount of incoming air is significant and potentially causes cooling of rooms in a wooden structure.

- With the opposite principle - the natural intake of air from the outside and forced exhaust, acceptable results are observed in cold living areas. Also, with this scheme, the cooker hood can be included in the general ventilation system of the house.

In the case of forced extraction, ventilation ducts are laid as conveniently, starting from each room. Usually pipes are used that make it possible to correctly install the fan unit where its noise will not interfere with the residents. If the climate is harsh and there are severe frosts, ventilation ducts or pipes are equipped with check valves, which can either be forced to heat or be located in a warm attic.

If a scheme with a natural hood in a wooden house is used, the channels for the passage of air should also be correctly made from pipes that extend outside the roof to a height of half a meter to a meter above the level of the roof ridge. In this case, the pipes at the end are equipped with ventilation fungi.

Ventilation system and hoods in houses from SIW panels

The so-called Canadian houses are sometimes called thermoses, since they do not have the smallest conditions for air to seep in, there are no gaps, holes or passages, and there is zero natural ventilation.

Therefore, making the right channels and passages with your own hands is vital. Not only to mount the hood in the kitchen, but also to neutralize the smell in the bathroom and provide a normal microclimate in the rooms.

SIP panels allow you to lay pipes inside. Doing it yourself is not difficult, you just need to remove part of the finishing plate and internal filler. For ventilation, sewer pipes of various sections are often used, however, nickel steel is better for the kitchen channel. This is due to the fact that the cooker hood can throw quite a hot stream of air into the ventilation duct.

When organizing hoods in a house from SIP panels, various principles are used:

- you can make only two main ventilation ducts - from the bathroom and kitchen. Sometimes two pipes lead from the kitchen, one of which is asbestos or metal, designed for the installation of a kitchen hood. An inflow of fresh air is easily made through windows that are open for micro-ventilation. Superchargers, which are usually located in the attic space, can be used to intensify the flow. In order not to make extra holes in the roof, the exhaust ducts are often combined into one pipe, having previously installed check valves so that odors from the bathroom do not penetrate the kitchen and vice versa;

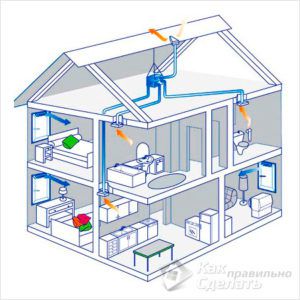

- The second option is to make a full range hood, which is a channel of pipes drawn from each room. In this case, in the attic, you must either make one conclusion in the form of a compact column that rises above the roof level (similar to the ventilation of panel houses), or combine all the channels into one and make a forced circulation system using a supercharger. With this scheme, the channels leading from the bathroom and kitchen are also equipped with check valves.

- Separate channels from the bathrooms and kitchen, combined in one exit

- Separate forced circulation channels

In practice, various methods are used that combine both principles of ventilation, in which a cooker hood can be installed without problems.

The best way by which it is better to make ventilation at home from SIP panels is to use breathers. This compact device takes air from the outside of the building, heats it and delivers it to the room. It also removes the exhaust air masses.By installing such a device in each room, it is not necessary to maintain a pipe system and it is possible to provide separate adjustment and an excellent microclimate in the rooms.

Ventilation of aerated concrete houses

It is impossible to make channels in aerated concrete walls that would not add particles of material, dust and ash to the flow of incoming air. Therefore, pipes are used. They are mounted in gates that cut directly into the wall, asbestos cement pipes, galvanized metal pipes or sewer pipes with a cross-section of 15 square centimeters are widely used.

You can create ventilation ducts in the walls and do it yourself. For this, details are used from wave slate, which is sawn into strips and folded in gates so that the wave peaks are directed in different directions. After that, the structure is sealed with a solution. The method is very simple and allows you to save, because you do not have to buy pipes.

Separate channels of a larger section are allocated from the bathroom and kitchen. If you plan to install a kitchen hood, be sure to use an asbestos-cement pipe. In the channel of the bathroom, galvanized steel can be used, since there is no danger of heating and deformation, which can cause cracking of aerated concrete.

Hybrid ventilation in two-story buildings

In wooden, frame or built from SIW panels of houses in two or more floors, you can apply the hybrid principle of building hoods. Wherein:

- the ventilation ducts of the ground floor show good efficiency, and since the pipes are located inside the house, they are not threatened with freezing and the occurrence of back draft, a natural exhaust occurs;

- to install the hood in the kitchen, spend a separate channel where it will be installed. Also, in this room there is a channel from the pipes for the natural departure of heated air outside the premises;

- The channel of the bathroom is equipped without any special requirements - it is simply assembled from pipes.

When using a hybrid type of hood in houses of several floors, it is not necessary to install check valves for the pipes of the bathroom channel and the kitchen hood.

The premises of the second floor are forced ventilation. For this, the entrance of the ventilation duct can be done directly on the ceiling. The right amount of exhaust air is provided by electric fans, which can be installed in the attic space. All channels from the pipes are led out through the roof outside the roof to a height of at least 50 cm from the level of the ridge, ventilation fungi are located at the ends.

Foundation ventilation

Ventilation passages for air intake under the flooring can also be made from pipes. In this case, the installation of all elements should be carried out directly during the construction of the foundation, since afterwards it will be impossible to reach them through the floor surface. In harsh climates with negative temperatures, you need to make dampers that will make it possible to block the external openings of the ventilation passages of the foundation.

Conclusion

As you can see, the methods of ventilation of a private house are largely similar. However, they have features that depend on the type of structure and properties of the material from which it is built. In practice, it is better to seek advice from specialized companies that have experience in organizing supply and exhaust systems in specific areas and that can take into account climatic factors.