What is ventilation at home? How to make it right? And is there a fundamental difference between the ventilation of aerated concrete and log houses? We will deal with these issues, and at the same time debunk some common myths about how to design ventilation in your home.

Prefabricated house ventilation

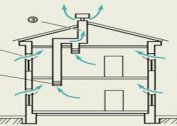

The ventilation system of prefabricated houses is a set of concrete structures assembled together, like a children's designer. The ventilation of all prefabricated houses is an uncontrollable natural type and is based solely on the use of natural phenomena. Air venting occurs due to the difference in temperature and pressure in the ventilation shaft and above the roof of the house. Atmospheric pressure forms in the apartments, which is made up by the supply air.

According to the house ventilation plan, the exhaust ducts are routed so that air flows do not flow from one apartment to another. It is correct to bring a satellite channel to each bathroom and kitchen at home, which on the next floor flows into the ventilation shaft. To prevent back draft in the ventilation of the last floors of Stalin's houses, air ducts discharge gases into the atmosphere, bypassing the common riser.

The air supply to the apartments is planned through ajar windows, door and window slots. Ventilation of prefabricated houses is not designed for modern construction technologies, which ensure complete isolation of apartments from the outside world. Therefore, without modernization, the ventilation of multi-storey buildings is inactive.

DIY ventilation upgrade

Dampness, crying windows and stuffiness make residents think about how to make ventilation in the house. Most often, attempts to make ventilation in the house with their own hands begin with the installation of an exhaust fan and a kitchen hood. Before you do it yourself, understand the principles of ventilation in the house:

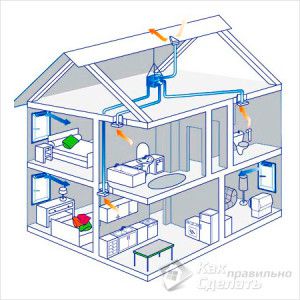

- The ventilation plan of the house includes a fume hood and intake.

- Inside the apartment provides free passage of air flows.

- Clean air is supplied to the bedrooms and living rooms, the exhaust is removed from the toilet, bathroom, kitchen.

This is a minimum of conditions for proper ventilation in the house. Properly installed ventilation in the house, in addition to the hood, provides air supply. For this, a variety of supply devices have been developed:

- wall and window valves;

- compact air handling units;

- ventilators.

Any of the listed devices will cope with the ventilation of the apartment in a multi-storey building, providing more or less comfort. Valves supply street air without heating, only filtering it. And here supply units and compact ventilators warm the influx without violating the temperature regime of the apartment.

Before starting work, order the diagnostics of general exchange exhaust ventilation in a Stalin-era building. If the mine is blocked by neighbors or littered with garbage - the exhaust fan will not save.

Ventilation in a log and timber house

The walls of the log houses “breathe”, so you can save on the installation of expensive ventilation systems. This can be heard in many construction companies involved in the construction of log and timber houses. Many buyers who do not know how to make ventilation in the house, believe.

The tree breathing myth is related to the ability of this material to absorb moisture. Indeed, untreated wood is able to somewhat regulate the humidity in the room. The amount of adsorbed moisture is enough to rot the wood. Therefore, devoid of any ventilation, a wooden house in 5 years will become completely unsuitable for housing.

This is raw wood. Modern building technologies widely use various types of sealants and impregnations, which protect the material from decomposition. The ends of the logs are especially intensively processed. By the way, it is the ends that let air in, giving some hope for the ventilation of the timber house.

The latest technologies for the construction of timber and log houses completely eliminate the presence of cracks due to poor caulking of the walls. They simply will not be caulked anymore and tow is used only to a limited extent. One more way for ventilation of a one-story house is excluded.

Up to one third of the air is filtered through the timber in a day - also an attempt to mislead buyers. A wooden bar interlayed with glue is not able to pass air at all. Therefore, the ventilation of the log home will have to do the owner.

Solution to the problem

A small timber house with an area of up to 150 square meters can be equipped with combined ventilation with your own hands:

- forced draft + natural influx;

- forced flow + natural draft.

In the first case, the ventilation ducts can be led out through the wall to the street, equipped with a fan and a check valve. If the winters in this area are severe, the check valve will have to be additionally heated to prevent icing. Fresh air enters the house through the supply devices (wall or window).

In the second case, the exhaust ducts are held upward, without turns and bends, through the roof and end with ventilation fungi 50 cm above the ridge. Inflow is ensured by mechanical air handling units.

With an area of more than 200 square meters. meters, it is recommended to install in the house ventilation supply and exhaust equipment with automatic control and recovery.

Ventilation of the house from SIP panels

SIP-panel houses are not for nothing called “thermoses” for their high thermal insulation. Energy efficiency is achieved due to the absence of cracks, cold bridges and special qualities of SIP panels themselves. There is no need to talk about any natural ventilation in such houses. All air exchange is forced. But here, there are more or less costly options for home ventilation from SIP panels.

The most inexpensive solution is as follows: exhaust ducts are carried out only in the kitchen and bathrooms. These are two separate channels, they are not combined so that the smell from the toilet does not penetrate the kitchen and vice versa. Thus, the house will have 2-3 air ducts (depending on the number of bathrooms). Before passing the roof, air ducts are combined together so as not to leak the roof in several places.

With a good exhaust, the inflow can be arranged by micro-ventilation through windows or supply valves. This method slightly reduces the energy efficiency of the building. Therefore, in such houses use ventilation air handling units with air heating, which are difficult to mount with your own hands.

The second option of budget ventilation of the house from SIP panels is the installation of breathers. Breathers - compact supply and exhaust systems for one room. At an o'clock the breather delivers about 100 cubic meters of air to the house. If there are 3-4 people living, it is correct to install at least two units for ventilation at home.

Each breather has two exits to the street: for air intake and exhaust. The air is heated by a recuperator or air heater. Installation of breathers will cost 2-4 times cheaper than full-fledged ventilation. But what is the plan of ventilation at home without extracts from the toilet and kitchen.

The most expensive and effective version of home ventilation from SIP panels is a supply and exhaust system that serves all rooms of the house. Such owners are frightened off by the need to lay ducts for many owners of finished houses. Therefore, it is desirable to design it as early as possible.

Brick house ventilation

When creating a brick house ventilation plan, special attention must be paid to the location of the ventilation shafts for natural ventilation. Brick ventilation ducts in private houses can be carried out:

- parallel to chimneys;

- set in separate risers.

In any case, the exhaust shafts are discharged through the roof. The thrust is formed due to the difference in air pressure in the house and over the roof, taking vapors and gases out of the home. This type of ventilation in a brick house is most effective in the cold season.

Channels are most often placed inside masonry walls:

- with a wall thickness of 0.38 m - in one row;

- with a thickness of 0.64 m - in two rows.

For ventilation of a two- or one-story house, it is most convenient to make channels of a square section of 14x14 cm. The brick is placed on a mortar for masonry walls, but clay-sand mixture can be made.

Prepare a solid burnt brick, buoys, test ball, and template in advance. As inventory buoys are used plank boxes with a cross section of 14x14 cm, a length of 10 bricks. The template is a board 2.5 x 0.14 x 0.025 m, holes are cut out in it, corresponding in shape and arrangement to future air ducts.

During masonry, the vertical must be checked with a plumb line. At the end of the work, the walls are squashed. Masonry is performed vertically. The distance to the corners and doorways is 38 cm. Thermal insulation must be laid between the exhaust shaft and the chimney.

Important points in the construction of home ventilation do-it-yourself:

- Set the template end to the inside of the transverse wall. With chalk, indicate the location of the holes and during the work from time to time check the template;

- The walls of the channels are made 1 brick thick;

- The solution is cut and the channels are laid back to back;

- Near the ventilation ducts, dressing is performed in one row;

- To make the mine stronger, you can lay bricks across the channel, but it will be more difficult to clean such a channel;

- Outflow channels are laid out from bricks hewn at the right angle (more than 60 degrees to the horizon). The diameter of the main and branch channels must match;

- Bandaging the walls and shafts is done with three-quarter and half-bricks;

- The buoys, which are rearranged from time to time, at the same time help to keep the shape of the channel and leave it clean;

- When squeezing the walls moisten and thoroughly wipe.

Deviation of the channel from the vertical impairs traction. In this case, there is only one output - an exhaust fan.

Ventilation in the house of aerated concrete

In houses made of aerated concrete, ventilation is laid out of plastic, galvanized or asbestos-cement pipes. A special duct extends into each room. You can combine exhaust ducts from the toilet and bath, as well as from the kitchen and sauna. This is done at the attic level, here all the exhaust pipes are insulated, insulation is also laid between them. The passage of the exhaust ducts through the roof is sealed with silicone or a special passage element is installed.

Pipes with a cross-sectional area of 15 sq. Cm are suitable for natural ventilation of a house from aerated concrete, for forced pipes can be taken a little thinner. In the blocks of aerated concrete, a hole of the right size is cut out. A pipe with a diameter of 12.5 cm is hidden in the wall opening with a width of about 13 cm and fixed with a solution. In the first block of aerated concrete, you need to fit the outlet, to which the ventilation ducts are attached. When passing through floor panels or partitions, holes must be coated with waterproofing.

If the opening of the wall is thinner, the channel is made of flat slate cut into strips. The strips are installed in the prepared opening, bursting and plastering.

You can make pipes for ventilation in the house with your own hands from wave slate. Two half-waves of slate are sawn off and connected to each other by wire. Such a pipe is installed on a brick base, plastered from the inside.

Do not lay ventilation ducts in external load-bearing walls! A separate mine is equipped for them, this is a convenient way to make ventilation in a finished house.

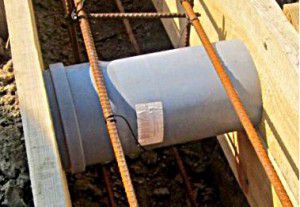

Foundation ventilation

Caring for proper ventilation at home, it is important not to forget about the safety of building envelopes: roofs, ceilings, foundations. The ventilation of a private house should be designed comprehensively, including auxiliary buildings and sewers.

It is advisable to plan the ventilation of the foundation of the house during the construction of the foundation itself. When the floor is installed on the ground floor, it is impossible to get to the necessary areas.

Ventilation of the foundation of the house is a system of holes (vents) located in the basement. The total area of vents and their placement depend on the size and location of the house.

Rules for arranging the ventilation of the foundation of the house:

- The area of one vent should be from 0.25 sq.m. You can make several adjacent holes of a smaller area or one larger. The total area of the holes should be 0.25 square meters for every 100 square meters of the area of the house.

- The airs are evenly distributed, otherwise areas of stagnation of air are formed.

- From a blind corner to the nearest air duct, a distance of up to 1 meter.

- On each side of the foundation, 2 vents are made.

If the cottage is located on a hill or a plain and is well blown by the winds, for quality ventilation of the foundation of the house, it is enough to equip 2 air ducts with a diameter of 0.15 m on each side.

If the vents are covered with nets or decorative grilles, the net area of the holes is reduced. Therefore, it is advisable to make one additional product on each side of the house.

In winter, the ventilation in the foundation of the house is closed, some vents periodically open for ventilation. Then the floor in the house will maintain its temperature, but no excess moisture will accumulate in the subfloor.

Ventilation in the foundation of the house can be done after its construction. The holes are made with a carbide drill with a suitable size. If the reinforcement of the base is rarefied during drilling, the foundation at this point will weaken.

Features of ventilation of two-story houses

Often, the ventilation system of two-story houses is designed only for maintenance of the first floor. And this is a big mistake, because heat and moisture rise from the bottom to the second floor, in summer the second (especially attic) floors are heated more by the sun. Therefore, they need ventilation.

Due to the height of the house in two-story buildings, natural ventilation can be very effective. But unlike ventilation of one-story houses, it can bring unpleasant surprises. For example, reverse thrust on the second floor, too strong thrust or none at all.

Trying to make ventilation in the house with your own hands, you should know:

- Separate exhaust ducts must be removed from the premises of each floor;

- You can not combine the channels of the bathrooms of the first and second floors;

- when calculating the ventilation of a two-story house, air exchange is first determined by the total area. After that, the resulting figure is "scattered" on the floors, taking into account the premises located there. Such an algorithm is quite complex and requires knowledge. Therefore, it’s quite difficult to design ventilation in your home;

- during calculations, the number of interior doors, partitions, and the design of the staircase are taken into account.

Passive House Ventilation

Passive houses do not require heating! They are heated due to the heat radiated by residents and household appliances, so each kilocalorie of heat should be stored and used rationally. Equipment that has been successfully used for ventilation of brick houses is unacceptable here. Cold air currents must not be let in, just as the loss of precious heat is unacceptable.

Therefore, ideally sealed passive houses are equipped with special supply and exhaust ventilation units with heat recovery. For passive houses, energy-efficient counter-flow heat exchangers and fans with EC engines have been developed. Such equipment returns up to 95% of heat from the exhaust air and allows you to spend on average 5 kilowatts / hour per 1 sq. square meter of the house per year. One of the most important requirements for ventilation of a passive house is the very quiet operation of the equipment.

A good addition to the energy-efficient ventilation of a passive house are soil heat exchangers (heat pumps). Devices receive heat directly from land or water. The air passing through the underground heat exchanger, even in winter, has a temperature of at least 17 degrees. In the summer, the hot street air cools in the same way. Therefore, in passive houses there is always a comfortable temperature.

Read more about what an energy-efficient house is and how to build it in the video: