Warm flooring is a modern method of heating due to the installation of heating elements under the floor covering: linoleum, ceramic, PVC tile, laminate. Previously, this technology was used as an additional source of heat, today TPs are used as a complete heating system. The design is distinguished by the absence of convection flows, uniform heating, high efficiency, ease of use, and safety. Types of warm floors are classified according to different parameters.

Water floor heating

The water floor functions by moving the coolant through pipes mounted under the floor. The system can be connected to an autonomous heating main.

The design consists of the following elements:

- air vent;

- closed branching of pipes;

- several fittings;

- fasteners;

- pump;

- locking fittings;

- collector.

The water floor has no loss of heat generated, which does not go outside the room, evenly distributed throughout the room and rising from the bottom up, which eliminates any discomfort for a person.

The options for underfloor heating depend on the choice of pipe material.

- Copper is notable for its high cost and complex installation. In many cases it is considered impractical to choose this option, despite the fact that copper is an excellent heat conductor and has excellent anti-corrosion properties.

- Metal-plastic - a common option at an affordable price with high thermal conductivity. This design shows optimal efficiency and has a long service life. The inner and outer layers of polymers guarantee pipes strength, reliability, and corrosion resistance. Structures made of metal-plastic easily withstand mechanical, hydrodynamic, thermodynamic loads.

- Polypropylene low cost, simplified installation. Popular for the installation of large-scale heating mains. Pipes have sufficient strength, tightness of joints, resistance to subzero temperatures.

- Made of crosslinked polyethylene. The chemical neutrality of polymers and amorphous make this type of product resistant to high temperatures. For heated floors use pipes marked PN 10, while the pressure of the coolant should not exceed 10 atmospheres. Tightness and durability of loops is provided by means of special fittings. The permissible length of the line of cross-linked polyethylene is 120 meters.

Advantages of a water floor heating:

Advantages of a water floor heating:

- profitability;

- environmental friendliness;

- safety for human health and life;

- durability, guaranteed service life up to 15 years;

- compliance with all sanitary standards;

- lack of need for regular maintenance;

- radiation of electromagnetic fields is excluded;

- aesthetics, CO is completely hidden from the eyes;

- easy adjustment of the level of heat supply.

It is recommended to install a warm floor in kindergartens, educational institutions - such heating reduces the level of development of colds.

The disadvantages include the high price, complicated repairs, high requirements for observing the installation technology.

Electric underfloor heating

Electric TP - heating cable heating cable located under the floor. The supply of electricity is regulated by a thermostat, which is designed to control the amount of heat generated.The peculiarity lies in the fact that it does not require a lot of additional parts in the form of a coolant, boiler, pipeline. Enough electricity and heating elements.

Types of electric heat-insulated floors:

- Heating cable. It consists of a core made of nichrome, brass, copper, covered with several layers of PVC insulation. Inside is a monolithic foil screen or wire braid that protects against electromagnetic radiation.

- Thermomats. Mesh roll with a fixed heating cable. Due to the small thickness of the wire, the design does not require the organization of a coupler; the device is installed directly in the adhesive layer, which saves space and does not affect the change in the height of the room. The thermomat has a five-layer insulation, is not afraid of high humidity, is controlled with an accuracy of 1 ° C. Differs in universality, lack of an electromagnetic field.

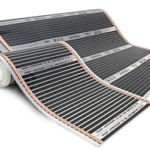

- IR film coating. Infrared TP is a modern alternative to conventional heating with a healing effect. IR radiation does not require large expenditures of electricity and has a positive effect on human health. In the process of ICTP, air ionizes, which kills pathogenic bacteria and eliminates unpleasant odors.

- Self-regulating cables. The design has the property of changing power in certain areas, taking into account the air temperature in the surrounding space. This saves energy.

- Heating cable

- IR floor heating

Electric TP has a number of advantages:

- unpretentious, universal installation;

- regulation of modes by means of a temperature regulator;

- lack of visual manifestations, aesthetics;

- application as the main or additional heating;

- long service life of more than 15 years;

- for the operation of the highway does not require a large amount of additional equipment;

- uniform heating of the room;

- safety.

The disadvantages of the electric floor include the serious cost of maintenance, the need for grounding, reducing the height of the room.

Laying and control system

Preliminary calculations are carried out, material and regulatory equipment are purchased. Installation is carried out as follows:

- In the screed: on the draft floor there is a hydraulic barrier, thermal insulation, mounting grid and heater.

- On the screed: the technology is similar to the first option, only instead of the second segment, the adhesive solution is applied.

- Under the tiles: the principle of work is the same as mounting on a screed.

The electric line is controlled by a temperature controller. The water floor is most often regulated by shutoff valves, a three-way valve.