Heat exchangers of heating systems - radiators and batteries - are presented in a wide variety. The right choice will help to avoid unpleasant consequences in case of accidents and breakdowns.

Design features of steel radiators

The construction of a residential building is a costly undertaking, requiring careful study and selection of components.

The components of the heating system are selected based on the parameters:

- cost;

- reliability;

- technical specifications;

- appearance.

Steel radiators are an option for home improvement.

Steel is a relatively cheap and technologically advanced material. The difference in the cost of iron radiators compared to aluminum or bimetallic becomes noticeable when installing heating in a country house, when you need to purchase 10 - 15 appliances.

Stamping and resistance welding, used in the manufacture, reduce the cost of design and cost of the final product.

The technical characteristics of most models allow the use of metal heating batteries in systems with a steam-water mixture pressure of up to 10 Atm. This indicator with a large margin covers the permissible loads in a private heating network (up to 4 Atm).

It is undesirable to use low-cost iron structures in houses with a centralized heat supply - during seasonal inspections or in the case of water hammer, the pressure rises to 16 Atm. Damage to the radiator will cause flooding of the neighbors or, which is much more dangerous, severe burns.

The appearance of modern steel batteries is suitable for any interior. Stand out products painted in various colors, but their price is higher.

Types of Steel Batteries

Wear resistance, flexibility, ductility - qualities inherent in steel. They allow you to make various types of products.

The main types of steel radiators:

- stamped;

- tubular;

- sectional.

Each has features that are considered when buying and operating.

Stamped Panel Models

In general, the technology for manufacturing products is simple.

- The metal sheet is stamped by squeezing stiffeners and giving volumetric shape.

- The sheets are connected by contact welding, so that a kind of closed container is obtained.

- To connect the steam-water mixture and drain the cooled coolant, two fittings are welded.

The finished product looks like one, two or three panels connected in a single housing. Between the panels, convection plates are installed that accelerate heat transfer.

A great influence on the safety of an attractive appearance is affected by the coloring method.

Choose products in the characteristics of which the manufacturer indicated cathodic electrophoresis. This is the most reliable coating used on an industrial scale.

A stamped steel radiator works on two principles:

- radiation into the space of infrared waves (heat);

- convection - the rise of heated air from a panel from floor to ceiling.

Advantages of panel metal heating radiators:

- relatively low price due to manufacturability and a minimum of materials used;

- attractive appearance, a wide selection of products;

- the ability to select power depending on the volume of the room;

- quick warm-up after supply of coolant;

- no need to put a protective or decorative screen;

- light weight facilitates transportation and installation.

At the same time, this type of heat exchanger also has disadvantages.Steel is susceptible to corrosion, especially in the warmer months. When there is no circulation of the coolant, cavities filled with air appear in the batteries. In these places, corrosion is more intense.

The same effect is caused by the salt contained in the coolant of centralized networks. In private homes, this is not so significant - you can use special additives or fill the system with antifreeze.

The second drawback is the poor resistance to water shocks, so flat iron batteries are not recommended to be installed in houses with urban heating. If, nevertheless, such a decision is made, be sure to install gearboxes to mitigate water hammer.

Inexpensive (600 - 1000 rubles) gearboxes designed for pressures up to 4.5 bar are designed for private homes. Devices for pressure 10 Atm, suitable for centralized systems, are 1.5 - 2 times more expensive than the steel radiators themselves. Thus, the meaning is lost in the purchase of inexpensive radiators. The absence of a gearbox will inevitably lead to battery rupture, flooding of neighbors or severe injuries from exposure to steam.

The sizes of panel products can be very different. In length from 40 cm to 3 meters, in height - 0.3-0.9 m. The power of the device also depends on the geometric dimensions. The characteristic can always be found in the passport. Also, heat transfer depends on the number of rows of panels in the assembly.

Tubular

For products, steel tubes are used, connected in a kind of lattice.

The pipes use thick-walled, which increases the price. Inside, the channels are coated with polymeric materials to prevent corrosion.

Thick walls guarantee enhanced performance in terms of resistance to water hammer. The operating pressure for this type of product is set within 15 bar, which allows for use in centralized networks.

The maximum permissible operating temperature of the coolant contributes to this - up to 130 degrees.

Dimensions depend on the thickness of the tubes and the calculated value of the power output. Length up to 3, height up to 1 m.

When buying, take into account the presence of bends for lateral or lower connection.

In addition to this, tube-type batteries are easy to wipe or wash, since there are no protrusions or bends.

The batteries warm evenly and exhibit thermal inertia. The effect is achieved due to the thickness of the steel. Products retain heat for some time due to their large mass.

Metal pipe radiators often play the role of additional designer accessories, therefore they are relatively expensive.

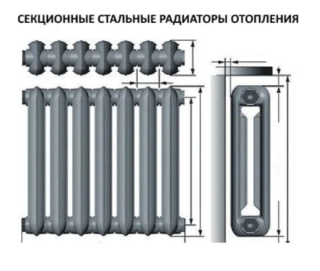

Sectional

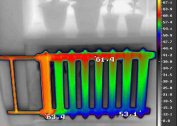

Metal batteries assembled from separate sections look very much like cast-iron radiators. At the same time, they have significant differences in manufacturing and technical specifications.

Metal batteries assembled from separate sections look very much like cast-iron radiators. At the same time, they have significant differences in manufacturing and technical specifications.

- Initially, separate sections are made by stamping and resistance welding.

- The next stage is the welding of sections into a single product.

The design is a symbiosis of panel and tubular radiators.

Low corrosion resistance and high price are the main indicators that limit the spread of this type of device.

At the same time, sectional iron batteries withstand high pressure and can be used for heating in apartment buildings.

The sections are connected by welding, which reduces corrosion at the joints, eliminates leaks between the components.

Relative disadvantage compared with aluminum and bimetallic products: it is impossible to reduce or increase the number of sections. The product is a single whole.

Network Connection Methods

Depending on which way the fittings go, the batteries come with a side or bottom connection.

Depending on which way the fittings go, the batteries come with a side or bottom connection.

There is no fundamental difference in manufacturing, but the lower version is more suitable for rooms with a design approach to decoration, so such products are more expensive. This is a purely marketing move by sellers.

Side connection can be used with any pipe routing options:

- vertical with the upper wiring, when the coolant "flows" along the risers;

- with the lower wiring in one- and two-pipe, dead ends and with the reverse movement of water.

With a lower connection, it will not be possible to apply vertical wiring, all other circuits are available.

The advantages of the lower eyeliner are the ability to hide the pipes in the screed or under the floor trim. Only 5 - 10 cm tubes under the radiator will remain in sight. In this case, a large heat loss is considered a relative disadvantage - the total heat transfer of the system is reduced by 10 - 15%.

To “turn” the connection of radiators from side to lower, special corner adapters are on sale.

Popular manufacturers

Steel radiators are present in the catalog of all well-known manufacturers of heat engineering.

- Kermi is a German industrial giant. A distinctive feature of the line of panel heat exchangers is their low resistance to pressure drops. The maximum indicator is 9 Atm at an antifreeze temperature of 110 ° C. Thus kermi is installed exclusively in private homes.

- Rommer is a Chinese brand, in the lineup there are only 4 models of panel steel radiators that differ in height. Rommer Ventil 300 (500), Rommer Compact 300 (500). Ventil is equipped with bottom fittings, Compact with side fittings. The numbers in the designation indicate the height of the device. The length varies from 40 to 200 cm. The manufacturer claims for all models a maximum pressure of 13.5 bar, which is enough for installation in apartments. Multilayer coating using phosphating technology. Products have been certified according to European standards, so there is no reason not to trust the quality.

- Buderus, Germany. A well-known brand, the steel radiators of which withstand up to 10 Atm and a temperature of up to 120 degrees.

- Lemax is a Russian manufacturer of heating equipment. The range includes any product from boilers to batteries. The core of the range of heat exchangers is Valve Compact and Compact steel panel radiators. The first option is for the bottom connection, the second for the side. Separately presented line of hygienic radiators. There are no parts for improving convection and decorative grilles in the design, which facilitates cleaning, less contributes to dust accumulation.

In addition to these brands are trustworthy: Lidea (Belarus), Conrad and Prado (both Russia).

Short memo for choice

When starting to look for radiators instead of old ones or for installation in new housing, the following characteristics should be considered:

- Power. It is believed that for every square meter of the room 100 watts of radiator power is needed. The calculation is approximate, you can more accurately find out from online calculators presented on manufacturers' websites.

- The maximum pressure that the structure can withstand.

- Maximum temperature. The parameter affects the quality of the connection of the outlet pipes with pipes and the resistance of the paint.

- Dimensions. When installed in the recesses under the windows, the radiator should occupy at least 65 - 70% of the length of the recess.

- Type of connection (lateral or lower) depending on the intended pipe layout.

- The presence of a temperature controller.

- Connecting sizes of branch pipes.

Any consumer will be able to choose a good steel radiator that will last a long time without breakdowns or accidents.