The circulation of the coolant in the heating circuit can be carried out naturally and forcibly. Due to the wide range of pumps, the second system is most often installed. In order for heating to be effective, it is necessary to choose the right circulation pump and install it correctly in the heating circuit.

Features of forced circulation

Water or other heat transfer fluid moves through the heating circuit due to circulation. It is of two types - natural and forced. In the first case, additional equipment is not required, the fluid itself moves through the system due to a properly designed circuit. In the second case, the coolant moves under the action of the circulation pump.

Natural circulation of water along the circuit has an important advantage - ease of installation and a minimum amount of equipment. But it is less effective, since you need to take into account many different nuances. If the tilt angles and pipe diameters are incorrectly calculated, the system will not work.

Forced circulation is more reliable and better. It has the following advantages:

- The diameter of the pipes is small compared to the natural circulation system. As a result, the cost will be lower. In addition, a pipeline with a small cross section does not spoil the appearance of the room.

- The ability to covertly connect radiators.

- No complicated pipe angle calculation is required.

- Versatility and efficiency.

The disadvantages include:

- The high cost of the pump. Also, for his work requires electricity, which will require financial costs.

- Risk of equipment breakdown.

- The system will not work when the power is turned off. It is necessary to provide for the possibility of autonomous power supply of the pump.

Despite its shortcomings, forced circulation is preferable to use in homes.

Installing a circulation pump in a heating system solves several problems:

- uniformity of heating of heating appliances;

- expansion of the heating system circuit;

- elimination of air congestion problems.

You can put in a finished heating system by tapping.

Pump selection

The heating system is connected to water. The pump usually runs on electricity, so its contact with the liquid is unacceptable. For this reason, all pumps for the heating circuit are divided into dry and wet.

Dry type

In the dry circuit there is a division into two sealed sections. In the first pump part, direct contact with water is carried out, and in the second electric part, power is supplied from the network. It is completely isolated from liquid.

The advantages of dry appliances include:

- high power

- high throughput;

- ensuring optimal pressure in the network.

Dry products are justified in large industrial buildings. It is better not to put them in apartments due to shortcomings:

- big sizes;

- installation complexity;

- the presence of a shaft that wears out over time and requires repair;

- noisy work.

When buying a pump, it is important to choose the place of its installation in advance and calculate the amount of water that it will pump. The best place to install is a separate room for the heating system.

Wet type

This type of equipment is suitable for apartments, one- and two-story private houses. Wet-type pump device: a housing with a closed electrical part that is connected to the pump chamber. It carries out pumping of the heat carrier. Tightness is achieved by using gaskets. At the inlet and outlet there are pipes and flanges for connecting pipes.

The electrical part is also divided into two parts. In the center is a glass in which there are all electrical mechanisms except the power harness of the starter. It is hermetically located outside the glass and does not come in contact with water. In the glass there is a rotor, on the shaft of which the impeller is mounted. To place the glass in the coolant, a valve is used to release air.

The disadvantages of the system include a decrease in efficiency. Advantages - low power consumption, easy installation and the ability to install on any part of the pipe. It is important that the glass is in a horizontal position, otherwise when installed vertically, the mechanism will overheat and will quickly fail.

It is important to ensure that no particles of plaque and dirt get into the equipment. For this, a cleaning filter is placed in front of the inlet.

Criterias of choice

Pre-selected dry or wet type. In residential buildings, the latter is installed. You also need to determine the voltage, power and performance of the pump.

For heating the apartment pumps with a frequency of 50 Hz and a voltage of 220 V. The voltage must be 220V, which is supported by additionally installed stabilizers.

Power is selected so that all performance is maintained. The higher it is, the more energy is needed to operate the pump. Class A, B, and C devices exist. Class A is characterized by minimal power consumption, but their cost is high.

When choosing equipment, you should pay attention to its operational characteristics. They can be found on the pump box or in the documentation for it.

The performance criterion is determined individually for each type of work. An optimal balance should be observed in the volume of distilled water and the electricity spent on it.

An important criterion is the range of operating temperatures. For modern models, it varies from 2 ° C to 110 ° C.

Pump installation

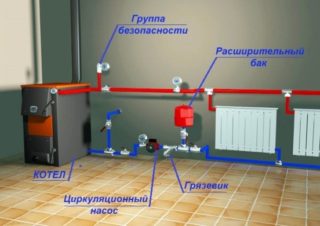

Installing the pump for heating a private house with your own hands is not difficult. First of all, you should choose the place where the device will be connected. The best option is mounting on a polypropylene pipe the return pipe before entering the boiler in the direction of water movement. There must be an expansion water tank in front of the pump. If it is open or membrane type, the pump can be installed in any part of the return.

New high temperature pumps can be installed on the feed pipe. They are able to withstand up to 110 ° C. In this case, all system parameters must be balanced. If this is not done, in extreme cold, when operating at maximum power, the coolant may boil and damage the system. Therefore, the recommended place on the supply pipe is the area away from the boiler, but before the first branching of the battery.

In large houses, two groups of supply pipes can be made. In this case, it is recommended to put your own pump on each.

There are no general recommendations for choosing a place. Each case is considered individually before installing the pump and considering all the features of the heating system and premises.

Step-by-step installation

For self-installation, you will need sets of adjustable wrenches, pliers, tow, sealant. Cranes, adapters, and overhangs of suitable diameters will also be required.Nuts are supplied with the pump. Work is associated with welding parts, so the master must be able to work with equipment.

The algorithm for the correct installation of the pump for heating:

- Assembly by a node with cranes. Two will be installed at the edges of the pump, one on a straight pipe.

- Assembling the pump loop. It is necessary to tighten the nuts, but do not tighten them. Tighten at the end after checking the system.

- Trying on the bypass loop and marking the cooking sites.

- Welding parts with each other.

- Assembling the assembly on the return.

- Tightening the pipe nuts.

At the end, connect the pump. The assembled system needs to be tested. Pump maintenance is carried out in operating mode. The filter is periodically cleaned and the pressure gauge readings are taken. In case of discrepancy with the average values, the device is removed and regulated by the master.

Popular manufacturers

The most popular pump manufacturers in the CIS include:

- Danish brand Grundfos and German Wilo. These devices belong to the high price category.

- The middle price segment is represented by decent models from Italian firms DAB, Aquario, as well as Chinese Sprut.

- The Vortex, Caliber, Oasis, Neoclima companies have cheap pumps.

Choosing a quality product is quite difficult. This is due to a large number of fakes and cheap low-quality goods. They differ from high-quality models in their short life, mismatch of technical characteristics, noisy work, strong heating of the case. In order not to change a broken product during operation, it is recommended to immediately choose a quality pump from a trusted manufacturer.