Pipes in the heating system are key. The speed of movement of hot water, heat loss and hydraulic resistance in heat supply depend on them. Along with steel and copper pipelines, polymers are widely used. How to make a polypropylene heating system with your own hands for a private house and apartment? To answer this question, you should familiarize yourself with the characteristics of this material.

Properties of polypropylene heating pipes

For the manufacture of this type of polymer, polymerized ethylene and propylene are used. As an improvement in performance, reinforced polypropylene for heating should be chosen. An amplifier layer is present in it, preserving the rigidity of the structure when exposed to high temperatures.

Before you make water heating yourself from polypropylene, you need to find out the technical qualities of these pipes. Unlike cross-linked polyethylene, they do not pass oxygen molecules, have the lowest specific gravity with sufficiently high strength characteristics.

Properly installed do-it-yourself polypropylene heating will have the following properties:

- High degree of thermal insulation. This allows you to reduce heat loss in highways. But at the same time, one cannot count on the heat transfer of pipelines in heat supply;

- Smooth inner surface provides minimal hydraulic loss. It also contributes to the absence of scale and deposits inherent in steel lines;

- Fairly good maximum pressure and temperature. The two-pipe heating system made of polypropylene will function normally with pressure surges up to 20 atm. and when exposed to a hot coolant with a degree of heating up to + 90 ° C;

- Minimum requirements for installation and maintainability of pipelines. In the presence of a special soldering iron, emergency situations can be solved independently.

Since you can install heating from polypropylene using the pipes intended for this, you should first familiarize yourself with the accepted classification. With the wrong choice of model, the probability of depressurization of heating will be quite high.

Before making heating from polypropylene, it is necessary to calculate the optimal thermal regime of the system. It should not exceed the operational parameters of polymer pipes.

Types of polypropylene pipes for heat supply

Professional installation of polypropylene heating begins with the choice of pipes. They differ not only in diameter and wall thickness, but also in other technical qualities.

Truly high-quality heating of a private house with your own hands from polypropylene is possible only with the use of appropriate pipes. Almost all information about their properties can be found in the markings on the outer surface. Some of the items do not need to be decrypted. But special attention should be paid to such parameters:

- Production material. For heating pipes, PP-R grade polypropylene is used. It is heat resistant. In addition to it, one can meet pipes of the PPH and PPB brands. With their help, you can organize a cold water supply system;

- Rated working pressure. It is designated by PN-10 symbols (16,20 or 25).For autonomous heating, it is possible to install polypropylene reinforced with fiberglass for heating PN-20. In centralized systems, installation of PN-25 pipelines is recommended due to possible pressure surges;

- Range of diameters, wall thicknesses and maximum allowable temperature effects. Data can be taken from the table below.

| Pipe grade | Diameter range, mm | Wall thickness mm | Maximum water temperature, ° С |

| PN-10 | 20-110 | 1,9-10 | +20 |

| PN-16 | 16-110 | 2,3-15,1 | +45 |

| PN-20 | 16-110 | 2,6-16,1 | +60 |

| PN-25 | 21,2-77,9 | 2,8-18,3 | +80 |

All pipes made of polypropylene for heating must have a reinforcing layer. It is made of aluminum foil or fiberglass. The latter are characterized by higher reliability, but also at a greater price. In violation of the technology of applying aluminum foil, it is possible to separate the outer or inner layer from its surface.

This phenomenon is quite common for handicrafts. Therefore, it is preferable to purchase reinforced polypropylene for heating using fiberglass.

There is a color marking of polymer products. Fiberglass reinforced polypropylene for heating will have a red longitudinal strip on the surface, indicating the possibility of use in heat supply.

Accessories and soldering rules for pipes made of polypropylene

The connection of polymer pipes can be performed in several ways - soldering, detachable or one-piece fittings, gluing. For the installation of water heating with your own hands from polypropylene, diffusion welding is best suited. The main connecting element in this case are fittings.

It is important that the quality of the purchased components is not inferior to the pipes. All fittings for pipes made of polypropylene for heating do not have reinforcement. This is offset by a thicker wall. They differ in appearance and scope:

- Couplings. Designed to connect individual pipes into a single highway. They can be either of the same diameter or transitional for joining pipelines with a draft section;

- Corners. Scope - production of corner sections of highways;

- Tees and crosses. Required for dividing the trunk into several separate circuits. With their help, a collector for heating is made of polypropylene;

- Compensators. Hot water provokes thermal expansion of pipelines. Therefore, before soldering the heating from polypropylene, compensation loops should be installed, which do not allow surface tension to appear in the main.

Before starting the soldering process, it is recommended to calculate the amount of all consumables: pipes, fittings and valves. For this, a heat supply scheme is drawn up indicating the configuration of each node.

During the installation of polypropylene heating, it is necessary to use a special type of shutoff valves designed for soldering.

Self soldering polypropylene pipes

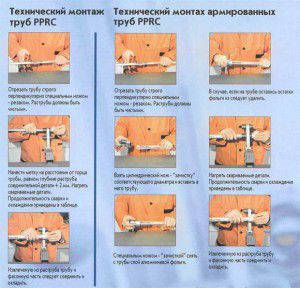

In order to make heating from polypropylene, a minimum set of tools should be purchased. It includes a soldering iron for pipes, special scissors and a trimmer. The latter is necessary for stripping the nozzles from the reinforcing layer in the soldering area.

Before soldering the heating from polypropylene, cut the required pipe size. For this, special scissors with a base for the nozzle are intended. They will provide an even cut without distortion.

For self-installation of polypropylene heating, you will need to perform the following steps:

- Degrease the soldering spot on the nozzles.

- Using a trimmer, remove the reinforcing layer from the heating zone.

- Turn on the soldering iron and set it to a specific temperature.

- After heating the mirrors, install the nozzle and coupling into the nozzles. Do not make axial rotations during heating of polypropylene.

- After a certain period of time, connect the pipe and coupling to each other.

- Wait for the final cooling.

With this technology, you can make a reliable heating system from polypropylene with your own hands. The advantage of this method is the possibility of soldering on already mounted sections of the line. In this way, you can quickly repair the heating of a private house with your own hands from polypropylene.

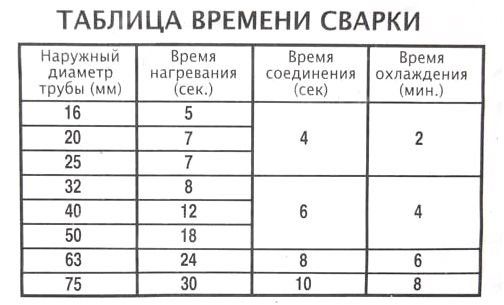

An important point during the independent soldering of water heating from polypropylene is the heating time of the workpieces. It depends on the diameter of the pipe and the wall thickness. With insufficient melting of the material, the diffusion process will be low, which over time will lead to stratification of the joint. If the pipe and the coupling are overheated, part of the material will evaporate, and as a result, a strong reduction in the external dimensions will occur. Therefore, for the installation of heating from polypropylene, the recommended heating time of the plastic should be adhered to, depending on its diameter and wall thickness.

Do-it-yourself polypropylene installation requires good ventilation in the room. When the plastic evaporates, its volatile components can enter the respiratory system.

For a small amount of work, you can purchase an unprofessional soldering iron worth up to 600 rubles. With it, you can solder the heat supply system from polypropylene for a small house or apartment.

DIY polypropylene collector

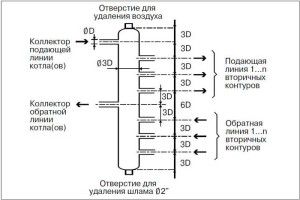

To complete the collector heating, a distribution comb is required. It is a pipe of relatively large diameter, on which several nozzles are located for connection to individual highways.

The manufacture of a collector for heating from polypropylene can only be used for small systems of underfloor heating. This is due to the relatively small pipe diameter and design requirements. With the independent manufacture of a collector for heat supply from polypropylene, the following components will be needed:

- Tees with transitional size 20 * 25 * 25 or 25 * 32 * 32;

- Shut-off ball valves 20 or 25 mm;

- A piece of pipe for connecting tees to each other.

Using a soldering iron, a collector is formed from polypropylene tees and pipes. On each branch pipe mounted ball valves. The disadvantage of installing such a design for heating from polypropylene is the mismatch of the cross-sectional dimensions of the pipes - the rule of 3 diameters is not respected.

That is why home-made collectors made of polypropylene components are not widely used. Exceptions are prefabricated structures that comply with all design rules.

For a two-pipe heating system made of polypropylene, a mixing valve can be installed instead of the collector to control the temperature of the coolant.

In what schemes can polypropylene pipes be used

Due to its high quality and reliability, reinforced polypropylene for heat supply is used in almost all types of systems. But is it always advisable? To resolve this issue, all factors affecting the installation, operation, and maintainability of the future circuit should be analyzed.

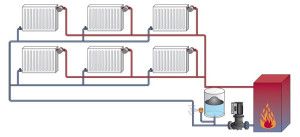

The complete set of the two-pipe heating system with polypropylene makes it possible to solve several problems at once. Firstly, the reliability and service life of pipelines will increase. However, this will only be relevant if the piping connection technology has been followed. The second advantage is the reduction of heat loss during the movement of the coolant through the pipeline.

But experts do not recommend doing the heat supply of a private house with their own hands from gravitational-type polypropylene. This is due to the following factors:

- Polypropylene pipes are needed for heat supply of large diameters - from 40 mm and more. Diffusion welding is not suitable for their connection - matching will be required using a special installation;

- The increase in the complexity of installation;

- Increased costs through the use of a profile welding machine.

From this we can conclude that fiberglass-reinforced polypropylene for heating is applicable to all heat supply systems except gravity. But in this case, the limitations are not due to technical characteristics, but to rational considerations.

Flush mounting in polypropylene heating walls is not recommended. It has a relatively large coefficient of thermal expansion, which can lead to an increase in the load on the external walls of the pipeline. Therefore, it is best to use schemes with an open installation or to make false walls.

The video material tells about the methods of independent diffusion soldering of polypropylene pipes for heating: