The weather is unpredictable. Long rains or heavy snowfalls are common in many regions. Streams of moisture rush down the roof. Uncontrolled water can bring big trouble. Puddles on the plot and damp walls of buildings can cause the destruction of the house outside.

A system of gutters and pipes will help to drain rain and melt water from the roofs of buildings, away from walls and foundations. It will fill the watering tanks.

In this article, we consider one of the options for the manufacture and installation of a drain from sewer pipes, made by hand. We will identify the pros and cons of this design.

Why do you need a drain

The drain consists of gutters and pipes. Brooks on the roof flow into a gutter, fixed under the roof of the building and longer down the pipes. On land, streams are distributed through a drainage system.

The drain consists of gutters and pipes. Brooks on the roof flow into a gutter, fixed under the roof of the building and longer down the pipes. On land, streams are distributed through a drainage system.

By controlling rainwater flows, the drain protects:

- Blind area and foundation from erosion.

- Walls from getting wet and further cracking of the facade in the cold.

- Plot in front of the house from the formation of puddles.

In summer cottages and household plots, water can be collected in special containers for irrigation.

Drains play the role of decoration. They create a complete look for the roof, positively affecting the look of the yard.

Why sewer pipes are suitable for this purpose

Drains are made of various materials:

Drains are made of various materials:

- galvanized iron;

- copper;

- shaped tin pipe;

- plastic;

- sewer pipes.

A drain from sewer pipes is a suitable solution for private households and farm buildings. Consider the advantages of this choice:

- The financial side of the issue. The purchase and installation of a finished drainage system will cost 3-4 times more expensive than a home-made one. To perform this work, no special equipment and tools are required. Sewer polymer pipes and fittings for them cost little money.

- DIY installation. Polymer pipes are lightweight. Mounting a system from them is not difficult, although some nuances need to be foreseen and designed.

- Appearance the finished drainage system will harmoniously fit into the design of the building and complete the image of the roof.

- Long service life. Polypropylene pipes are not afraid of corrosion and do not need to be painted. They are designed for long-term use.

- Easy replacement. In case of damage to the drainage system, during operation, the replacement of parts is not difficult, since everything has the same size.

How to properly place the drain pipes

Similar work should begin with the project.

Similar work should begin with the project.

Bypassing the construction, draw on the leaflet an approximate drainage scheme. It is necessary to consider how the gutters will be located, where the gutters, drainage systems on the ground will be located. It is necessary to provide for the need to use a water collection tank for irrigation, if necessary.

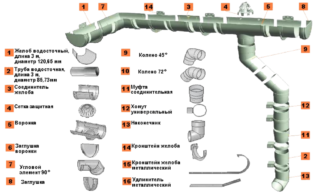

The next stage is a detailed study of each individual node. Counting fittings that we will need to connect pipes and gutters. We count and write down corners, tees, plugs.

We measure the length of the gutters and pipes. The maximum distance between the drains is 10-12 meters. We get two gutters when sawing one pipe. The diameter of the pipe for the gutter is 110 mm, and the pipes, if desired, can be 50 or 110 mm.

When designing a drain, pipe material should be considered.

Sewer pipes come in polyvinyl chloride (PVC) and polypropylene. PVC pipes are designed for underground installation and are not suitable for a drain. The sun and the difference in street temperatures will destroy them.

Polypropylene pipes are white, gray and brown and meets the operational requirements:

- White and gray pipes for the southern regions. They are not designed for frost.

- Brown pipes are thicker and are used for outdoor installation. They are resistant to frost, but do not tolerate heat. Used in the central and northern regions.

For the installation of the structure we use factory clamps. In order to save money, fasteners can be made independently from a galvanized strip with a width of 20 mm. The number of clamps is calculated at the rate of 1 pc per 50-60 cm.

We prepare the fasteners depending on the material of the walls to which the drain will be screwed.

When designing, it is necessary to take into account the location of the pipes at the junction. The pipe from which water is poured must enter the receiving pipe, and not vice versa. We pay attention to the angle of inclination of the gutters. If it is not taken into account, water that does not completely flow out in the winter will freeze, interfering with runoff and creating excess weight of the gutter.

In the ground or underground parts, we also plan a slope.

In cases of impossibility of water drainage to the side, special drainage pits are planned. Their depth is about a meter. They are filled with large rubble or broken brick.

Phased installation and operation of the system

Installation work begins with cutting pipes lengthwise into two parts. We dissolve the pipe in half with a grinder or an ordinary hand saw. The plastic is soft and sawn quite easily. The main thing is to cut exactly according to the markup.

Installation work begins with cutting pipes lengthwise into two parts. We dissolve the pipe in half with a grinder or an ordinary hand saw. The plastic is soft and sawn quite easily. The main thing is to cut exactly according to the markup.

The gutter is mounted on the edge of the rafter system, on the cornice or on the roof. The gutters should go one-third of the pipe over the roof and protrude two-thirds. In this case, the flow of water will enter the gutter. We lay the slope towards the funnel (0.5-1 cm per meter). We calculate the total bias on the side. Having outlined the beginning and the end we connect them. This will ensure a uniform slope.

The top of the gutter is 3 cm below the edge of the roof. This will protect the structure from snow coming off the roof.

The system is assembled from top to bottom. First, gutters are hung, then drainpipes. The distance from the pipe to the wall is at least 10 cm. The gutter joints are fixed with self-tapping screws and sealant.

To protect the system from leaves and accidental debris, a mesh is mounted in the gutter. It is attached to the edges of the gutter with metal clips.

Conclusion

Proper design of the drainage system, the correct calculation of components and the availability of elementary tools will help to carry out installation without the help of specialists. This will reduce the expenditure of funds.

A self-assembled system from sewer pipes, the drainage system will not only save the house and the site from destruction by storm water, but will also serve for more than one year.