Natural moisture retention on the surface is a feature of flat roofs. It accumulates due to rains and melting snow. For the prevention of flooding of the upper floors and flights of stairs, special devices are used. A receiving funnel for storm sewers on the roof timely removes water from the roof, protecting institutions, apartment buildings and private houses, industrial facilities with equal success.

Purpose of funnels for storm sewers

The main objective of the products is the removal of fluid from the roof. To do this, a gutter mechanism is installed on the roof, combining several funnels. They are mounted in a certain sequence, covering the entire surface. Through them, water flows through pipes into the sewer, ravine or ditch, for the territory of the object.

Funnels must meet certain standards:

- durable, waterproof contact with the roof waterproofing system;

- a sufficient length of the pipe to connect to the riser in the attic or in the subceiling room;

- filtration system protecting the pipe from blockages.

Together, these parameters will ensure the rapid removal of excess fluid from the roof.

Types and arrangement of funnels

There are many types of storm funnels, combined in 2 basic categories:

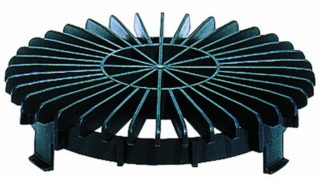

- flat models with gratings;

- bell-shaped modifications.

In the first case, installation is made on monolithic roofs without a sand layer. Lattices are made in the form of cells, squares, ovals, etc. All storm runoff goes on top, so the grill is at roof level or slightly lower. Galvanized wire mesh, umbrella or inner cone protects against debris.

The bell-shaped design includes the funnel itself, an internal umbrella, and a bell (glass and lid). The edges are equipped with special teeth that clamp the roofing material tightly adjacent to the surface. Inside there are ribs that open a small gap for water flow. As a result, leaves, paper and other debris do not enter the pipe, preventing clogging.

Production materials

When choosing a material, the owners of the object and specialists are guided by its ability to withstand the effects of moisture. Because of this, preference for a long time was given to cast iron and galvanized steel. Today they are also widely used, but are largely superseded by plastic, which has managed to prove its effectiveness.

- Cast-iron monolithic models. A common version adapted to tightly clamp the roll surface. It forms a waterproofing carpet, quickly removing excess moisture. Cast iron is also in demand due to decorative properties - the bell-shaped designs created from it look representative.

- Steel modifications. The reliable option used both in trellised models, and in caps. Funnels are created from semi-boiler, asphalt, galvanized types of iron, which guarantees a long service life and corrosion protection. Operational properties are practically not inferior to cast iron, while steel is much cheaper.

- Plastic option. It is characterized by increased practicality and ease of installation. Such designs better withstand the effects of moisture, temperature and other environmental factors. The service life is not limited, and the price is much lower, which is especially true when picking industrial facilities.

The choice of material is determined by the characteristics of the object, including its area, appearance, aesthetic requirements.

Features of the installation of funnels on the roof

The installation of structures, their number and the interval between funnels depends on the characteristics of the object: area, configuration, rain volume and other parameters. In practice, the distance between the 2 elements is about 25 meters, which is enough for timely drainage. A smaller amount leads to blockage of the funnels, followed by the accumulation of liquid on a flat surface.

All components are connected to drainpipes, in case of overload, a backup system is formed. It is activated during spring snowmelt, heavy rainfall or during prolonged rains. In this case, it is important that the receiving part is not clogged.

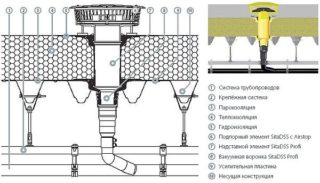

Installation is carried out in several stages:

- The inner element is inserted into a special hole on the roof. Fasteners should not be rigid.

- The outer part is inserted from above, passing it through the roofing carpet and insulation. A seal ring is placed between 2 elements.

- The cap apron is installed on the roofing lining and an additional waterproofing layer.

- A roof covering is placed in the funnel bowl, which is fixed with a ring and fixing components.

- The process completes the installation of the protective grill.

Success is determined by competent work planning and the qualifications of specialists.