Storm sewers are an important attribute of communications established in the city and of a personal plot. One of the important elements of the system are grates for drainage trays. The functionality of the storm and the appearance of the territory depend on their installation.

Purpose of drainage gratings

Arrangement of stormwater and drainage is possible with the help of drainage trays to drain excess moisture. For their manufacture, concrete, metal and polymers with a smooth surface are used. When installing trough structures at an angle, a uniform drain of excess water is ensured even after prolonged rainfall. They cover the device with special gratings that can prevent branches, leaves and other debris from entering the sewer.

Lattice parts also have additional functions:

- Safety. By closing the drainage cavity, they allow you to avoid getting injured by people and animals by negligence.

- Creation of unhindered access to transport. Drainage grilles placed at the same level with the surface of the road surface allow cars to maneuver and withstand significant loads.

- Landscaping - a street or a personal plot.

In appearance, the drainage grate for draining sewage on the street can be slotted or cellular. Both types are functional, the choice is due to decorative preferences.

Types and sizes

In size and shape, the grating parts must correspond to the trays that they cover. The size of the gratings depends on the width of the hydraulic section of the chute element and is indicated in the marking: from DN95 to DN500. The standard tray length is 1 m, although they are more elongated. Width - in the range of 14–400 cm.

Lattices for storm sewer systems are divided by load class:

| Class | Load (t) | Destination | Popular models |

| AND | up to 1.5 | Are mounted on personal territories and paths for pedestrians. | Storm plastic, stamped steel galvanized, copper water intake, stamped steel stainless. |

| B | up to 12.5 | Used in car towns, in car parks. | Cellular galvanized steel. |

| WITH | up to 25 | Are established on highways or gas stations. | Stamped stainless steel, cast-iron slotted and mesh. |

| D | up to 40 | They are able to maintain the weight of the truck and are placed on the tracks where such vehicles are allowed to travel. | Cast iron slotted and cellular. |

| E | up to 60 | They are installed in truck parking lots, terminals, warehouses. | |

| F | up to 90 | They are used in airports, military bases, in areas of heavy heavy machinery. |

The latter type is rarely used and only in places with extremely high load on the road surface.

The cost of the product also depends on the size and load class. The higher the last parameter, the more expensive: the reinforcement of the gratings is carried out due to their thickening and additional processing of the source material.

Production material

Subdivided lattice products according to the material of manufacture. The scope of the details also depends on it:

- Cast iron elements are used for most of the linear drainage systems, which are installed in areas with constant friction and high pressure.

- Stainless steel metal gratings are used at large gas stations, roadsides, near industrial plants and in locations where there are high requirements for the anticorrosive characteristics of the material. To reduce the cost of stormwater drainage, galvanized steel is sometimes used.

- Plastic grilles are used in places with light loads: on personal plots, walkways for pedestrians, parks and squares. Their installation on roads with a dense stream of movement of freight vehicles is not allowed.

- Copper products can withstand only a small load and are used as decor.

- A concrete tray is inexpensive, but hard to mount

- Plastic products are the least durable and do not withstand high loads.

- Cast iron tray

In places with increased load, it is desirable to use lattice elements made of cast iron. They have a lot of weight, but are as hardy as possible. A cast-iron grate for covering large drainage trays will require installation of special equipment. To improve corrosion resistance, they are galvanized. To ennoble and give decorativeness, paint on metal.

Installation Rules

Before installing the grill, the tray itself must be correctly mounted. The installation procedure depends on the material from which it is made.

Before installing the grill, the tray itself must be correctly mounted. The installation procedure depends on the material from which it is made.

Plastic trays

Installation of polymer structures is carried out in stages:

- A ditch is dug in accordance with the drawing in the area where the installation of the tray product is supposed.

- A concrete substrate is created by pouring the mortar in a uniform layer to the bottom of the ditch.

- Plastic trays are placed in the trench in the center.

- Slopes are poured with concrete to ensure the stability of the drainage structure.

Connect the trays in a single butt construction. For convenience, a tongue is made on one side of the tray, and a groove on the opposite side. For an angular connection, a small hole is cut in the side wall and the products are joined at an angle of 90 degrees, they are sealed and a plug is installed.

Fix the grate on the plastic tray as follows:

- Install the main mounting system in the tray element by unscrewing the bolt from it.

- Fix the hardware in the groove on the lattice.

- Tighten the screw - firmly, until it stops.

The stamped lattice is fixed quite simply: bend the locks around the edges and fix the part in the tray.

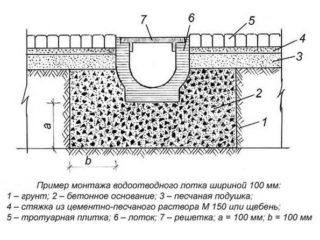

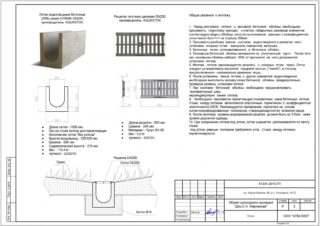

Concrete trays

Products are manufactured with both a rectangular and a round inner surface (for example, variants of the Aquastock brand). The latter let sewage through better. Installation of both those and others is made according to one scheme.

Products are manufactured with both a rectangular and a round inner surface (for example, variants of the Aquastock brand). The latter let sewage through better. Installation of both those and others is made according to one scheme.

Tray structures are installed in a previously dug trench on a concrete pad. The thickness of the layer is determined depending on the degree of load. The base is usually made from concrete B25. The fastening of the sides is performed in the form of slopes.

Reinforced concrete trays are docked to each other and sealed. With the angular connection of the drainage system, the necessary part of the side wall is cut out.

For better drainage of moisture flowing into the channels, it is necessary to create the necessary slope in the direction of the water discharge point or the central receiver.

Thermal seams are formed in the direction of the drainage line by notches at a distance of 20 mm from each other to prevent deformation of the system during seasonal temperature differences.

Lattices are attached to concrete using special screws. They can be removed for cleaning. The top of the installed grating must always be below the surface of the coating by 0.5 cm.

It is best to connect the chute chain to the sewer lines through a sand trap. The pipeline from it to the first well is performed using a pipe section with a bell and smooth walls.

The correct selection of lattice elements and their strong fixation to the trays are important for maintaining safety on the roads. A vehicle passing even at low speed is quite capable of knocking out an unsecured grille, creating an emergency.