Perforated drainage pipes provide water drainage, collect moisture from the site and transport it. When installing the filter, the sewer system is protected from mud clogging.

Scope and principle of action

The drainage system reliably protects the foundation of buildings, and also does not allow rain and groundwater to accumulate on the site. This is especially important for areas located in the immediate vicinity of marshes, a humid lowland or near a body of water, as well as with a high level of groundwater.

The drainage system reliably protects the foundation of buildings, and also does not allow rain and groundwater to accumulate on the site. This is especially important for areas located in the immediate vicinity of marshes, a humid lowland or near a body of water, as well as with a high level of groundwater.

Due to the decrease in humidity, mold will not form on the walls of houses. The territory is protected from the formation of puddles, ice in the cold season. In gardens and gardens, plants will not suffer from excess moisture and will not rot.

It is most effective to use perforated pipes made of polymers in geotextiles for drainage systems. The principle of operation of the perforated drainage system is as follows:

- Water from the surface and from the soil enters the sewer system through perforation.

- Drains are discharged through a pipe into a well tank.

- A case made of geotextile or geotextile serves as a filter from debris and sand.

Pipes are already sold with a filter shell or wrapped with material immediately before laying in a trench. Without this, the system will constantly clog up and will not be able to work normally.

Specifications

The material for the manufacture of pipe segments are:

The material for the manufacture of pipe segments are:

- polyethylene (HDPE, LDPE);

- polypropylene;

- polyvinyl chloride.

Previously used asbestos-cement and ceramic products, but now they use polymer versions of perforated pipes. They are lighter, easier to install, cheaper and more resistant to negative external influences. With their low weight, they have high stiffness characteristics, which give them special ribs that contribute to an even load distribution even at great depths.

Polymer pipes are single-layer or two-layer, most often with a corrugated surface. With a small thickness of the walls, they do not lose rigidity. For this reason, even products of large cross-section have a relatively small mass, which greatly simplifies installation.

In pipelines of two layers, the inner surface is made smooth, which allows debris to move and reduces the possibility of clogging of the system. Models made in one layer have a corrugation inside and out. They are more flexible, so they are suitable for creating drainage near buildings.

In pipelines of two layers, the inner surface is made smooth, which allows debris to move and reduces the possibility of clogging of the system. Models made in one layer have a corrugation inside and out. They are more flexible, so they are suitable for creating drainage near buildings.

Due to the increased rigidity, two-layer pipe products can be carried out to a depth of 6 meters. Single-layer pipes have a limit of up to two meters.

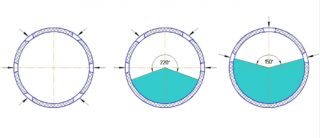

Perforate pipes in whole or in part. In the first case, the holes are located at a distance of 60 degrees around the circumference, respectively, along the cross section there are 6 perforation holes of 1.3 mm. With regard to partial perforation, only three holes are provided around the circumference of the product, which contributes to a more rapid discharge of waste water.

Pipes are produced in six and twelve meter lengths or in rolls. Pipelines are distinguished by the size of the section. Sizes - 110, 160, 200 mm. For household plots, models with a diameter of 110 mm are recommended.

Flat drainage pipes, also with perforation and in the filter, are popular. They have higher compressive strength, so the system can be laid at the very surface and save on earthwork. Flat models fold more compactly, which simplifies transportation. With all the efficiency, water is removed no worse.

Feature Selection

The main criteria for selecting parts of the drainage line are the degree of rigidity and the location of the perforation.

The first indicator depends on the depth of the laying of pipe lines: they must withstand the pressure of the layer of earth located on top. When purchasing pipes, pay attention to the marking indicating the stiffness class:

- SN 2–4 are suitable for depths up to 3 m;

- SN 6 - up to 4 m;

- SN 8 - up to 10 m.

Additionally, it is required to take into account the depth of underground sources, the amount of precipitation and the installation method of the drainage complex. These indicators are taken into account when choosing a perforation pattern. If holes run across the entire surface around the pipe, it is chosen to lower the groundwater level, to remove the effects of heavy rainfall and snowfall.

For storms, products with perforation of segments in one-third or two-thirds of a circle are suitable. Half-openings are characteristic of universal pipelines.

Choosing pipes, it is necessary to take into account their cost. The price per linear meter of perforated drainage pipes in geotextiles depends on the size and manufacturer. On average, a meter of a pipeline with a cross section of 110 mm costs 55 rubles, 160 mm - 110 rubles and 200 mm - 185 rubles. For flat pipes, the price per linear meter starts from 75 rubles.

Rules for installation and installation

It is possible to lay perforated piping in an open way on the surface. In the role of a drainage system are channels, gutter or pipe segments with holes in the upper third, installed at a depth of not more than half a meter. They can be left open, covered with a grate or covered with gravel that acts as a filter. The method is used when installing storm sewers along roads and pedestrian walkways, along the perimeter of buildings.

It is possible to lay perforated piping in an open way on the surface. In the role of a drainage system are channels, gutter or pipe segments with holes in the upper third, installed at a depth of not more than half a meter. They can be left open, covered with a grate or covered with gravel that acts as a filter. The method is used when installing storm sewers along roads and pedestrian walkways, along the perimeter of buildings.

Closed installation technology, involving the deepening of pipes into the ground, is more common. When arranging a deep drainage system, it becomes possible to divert underground currents located above the level of pipe laying. A similar technique is suitable for draining the earth and moving water from the places where it accumulates - gutters, summer showers, baths or pools.

System installation steps:

- Make a scheme of highways and mark the territory.

- Dig a trench to the required depth, taking into account the state of the earth, the level of underground currents and the load class of the selected pipes. The ditch should be 40 cm wider than the outside diameter of the pipeline. The ditch is made with a slope of three degrees to the drain hole.

- At the bottom of the trench, lay out a sand and gravel pillow. The thickness of the sand layer is not less than 100 mm, taking into account compaction, the upper crushed stone layer is not less than 200 mm.

- Connect the pipe sections with couplings.

- Check the slope using a regular cord taut along the entire pipe.

- At turning points and overfalls, arrange inspection wells with covers to clean and monitor the condition of the drainage system.

- Fill the pipes with gravel first, then sand, and then a layer of soil. Sometimes backfilling is only crushed stone or expanded clay.

Effluents are discharged into an open water body or rain sewer. A check valve is installed at the end of the drain pipes. If it is impossible to ensure such an exit, it will be necessary to create a collection well from which the collected fluid is pumped out from time to time.

Proper selection of a perforated pipeline and proper installation will significantly increase the service life and efficiency of the drainage system.