If household water flows into water bodies or into the ground without treatment, the environment suffers greatly. To prevent an environmental disaster, a variety of methods for cleaning contaminated wastewater are used.

The main methods of purification

Technological processes for the purification of domestic sewage are very effective. After passing through treatment in VOC, clarified water can be used again for watering the garden or for technical needs.

Technological processes for the purification of domestic sewage are very effective. After passing through treatment in VOC, clarified water can be used again for watering the garden or for technical needs.

Most often, the following methods are used to clean drain liquids:

- biological;

- mechanical;

- physical and chemical.

In order to clarify household and domestic wastewater, due to its simplicity and effectiveness, the first two cleaning methods are usually used.

Mechanical methods

During the application of any methods of clarifying contaminated liquids at the initial stage, mechanical-type techniques are usually used to separate coarse impurities. The technology of mechanical cleaning is the simplest and most affordable. For its implementation, contaminated liquid:

During the application of any methods of clarifying contaminated liquids at the initial stage, mechanical-type techniques are usually used to separate coarse impurities. The technology of mechanical cleaning is the simplest and most affordable. For its implementation, contaminated liquid:

- defend;

- filter;

- filtered.

The process occurs due to the use of coarse filters or in slop constructions through the deposition of heavy components under the influence of gravitational forces. Mechanical cleaning contributes to the removal of approximately 60–70 percent of contaminants from domestic wastewater.

Sludge facilities are used for cleaning sewage liquids, which are sent to them not only from residential, but also from industrial complexes.

In the course of sedimentation, it turns out to eliminate most of the oily impurities that appear with industrial effluents. Mechanical cleaning is used by car wash owners and oil refineries.

Cleaned mechanically and stormwater. To do this, sand traps are connected to the highways. The composition of precipitation that collects from the surface of the earth contains:

- soil impurities;

- branches

- foliage;

- pebble inclusions.

Sand traps hold up large debris, preventing it from clogging stormwater.

Bioremediation Methods

The technological process consists in the use of aerobic and anaerobic microorganisms capable of processing complex organic components in sewage. In this case, they decompose into gas and water.

Aerobic microorganisms need oxygen for life. To increase the cleaning efficiency, it will be necessary to create suitable conditions by installing an aeration system.

Anaerobic bacteria do not require oxygen, so they are able to live in sealed containers. A by-product of their livelihoods is methane. Installations in which purification is carried out using such microorganisms are equipped with a ventilation system.

Cleaning standards

Facilities and devices for wastewater clarification should provide the necessary level of treatment - this is controlled by law. The most stringent rules govern the operation of sewage effluents emanating from industrial facilities. The norms provide for the possible concentration of each substance in a clarified liquid separately.

For domestic wastewater requirements are not so stringent. However, the regulations still do not allow the discharge of wastewater without treatment into open water or soil. For this, homeowners can be held accountable.

There are no strict requirements for wastewater that is discharged after being cleaned into the ground. It is important for the homeowner that a relatively clean liquid enters the soil.Otherwise, he can bring his territory to such a state that living in the house will become impossible.

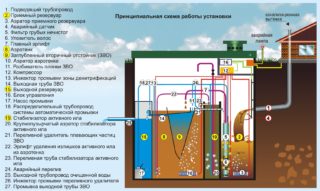

Types and principle of operation of VOCs

Local treatment facilities for domestic wastewater contribute to the processing of waste into a relatively safe liquid substance that can be used for technical needs or discharged into the soil.

Local treatment facilities for domestic wastewater contribute to the processing of waste into a relatively safe liquid substance that can be used for technical needs or discharged into the soil.

VOCs used for bio-treatment:

- Septic tanks are hermetic chambers into which sewage is discharged. Anaerobic microorganisms that process sludge and contribute to the purification of water live there. The liquid after the septic tank requires additional purification, for example, in a filtration well, before it is discharged into a reservoir or soil.

- Septic devices with biological filters. The principle of operation of the biofilter is to leak water through the thickness of coarse-grained material (crushed stone or sand), which is covered with a film of special bacteria. According to this scheme, filtration fields and well installations work. When sewage passes through a biological filter, due to microorganisms, the processes of oxidation and decomposition of organic components are activated.

- Bioponds - artificial water bodies with a depth not exceeding a meter. In them, contaminated liquid after mechanical cleaning is processed due to the action of bacteria. To accelerate the activity of microorganisms, it is necessary to warm the reservoirs with sunlight: in the Central Russian winter, these ponds have low productivity and are almost never used. Strengthening the activity of aerobic bacteria is also done through forced aeration.

- Aeration tanks - hermetically sealed installations that use forced aeration. To process the liquid faster and more efficiently, use activated sludge containing the necessary microorganisms in its composition.

- Deep cleaning stations. The facilities are used for complex clarification of wastewater with maximum effect. After passing through them, the liquid becomes purified to 98%. Water is driven through several different filters and treatment facilities.

Any bio-purification methods are applied exclusively after mechanical treatment of wastewater, for example, their sedimentation.

To clarify wastewater at enterprises and in residential complexes, a membrane bioreactor is increasingly being used. It combines bio-treatment with activated sludge and mechanical membrane filtration. The membrane module is used to separate sludge and is an alternative to the deposition of this substance in classic biological treatment plants.

Advantages of bioreactors:

- compact dimensions with high productivity;

- the use of old cleaning complexes when updating equipment;

- the ability to work with a significant accumulation of activated sludge.

There are two types of biological reactors: with internal and external membrane placement. In the second embodiment, the filter is isolated from the process chambers, and the installation of an intermediate pumping pumping equipment is necessary.

Among all local systems, only membrane biological reactors and deep-purification stations make it possible to obtain clarified water so that it can be discharged into natural water bodies or used in an irrigation system for irrigation. Despite the fact that these plants are not cheap, the absence of additional stages of pumping or wastewater treatment makes their purchase advisable.