Concrete trays are used to drain water in drainage and stormwater systems. Their proper arrangement allows you to get rid of excess moisture in the streets and to avoid the appearance of puddles, waterlogging, destruction of buildings and road surfaces.

Design and varieties of concrete trays

The device tray is quite simple. They are produced in the form of rectangular or rounded gutters. Designs are made with a drainage grate (usually cast iron, but sometimes steel or even plastic) or without it. Unlike open products, they have grooves or other systems for securing the lattice element.

Another variety is slotted trays - their upper side has slots that perform the function of a grating.

There are types of concrete trays that are made with an additional vertical drainage system or with slopes inside - up to 0.5 cm.

Manufacturers follow the requirements of GOST 21509-85. In accordance with it, products differ in type, load class, size and shape. Additionally, the rules of transportation, manufacture and installation are indicated.

The blind area and drainage allows the trays to protect buildings from sewage. The higher the throughput of the products, the greater the operational life of the road and pavement.

Intended classification

The scope of the trays involves the arrangement of storm sewers near residential buildings or industrial facilities. When choosing it is important to consider the degree of load on the system. Errors made in the calculations can cause the drainage structures to cope with external pressure and fail.

According to the load class that the reinforced concrete can withstand, the trays are divided as follows:

| Class | Maximum load (t) | Scope of application |

| S250 | 25 | Highways with medium traffic. |

| D400 | 40 | Car parks, high-traffic highways, gas stations. |

| E600 | 60 | Highways, industrial complexes, truck parking lots. |

| F900 | 90 | Territories of airports, military and industrial bases. |

For small loads (up to 12.5 tons), plastic trays that are easier to install are often chosen. Reinforced concrete products are also divided into two series - standard and reinforced. The former hold a load of up to 25 tons and are installed on roads with narrow (up to half a meter) curbs. Reinforced can withstand up to 90 tons and are used in airports, industrial areas, in heavy vehicle parking.

Tray classification by purpose:

- Culverts. Suitable for gravity drainage.

- Stormy. Needed to collect and discharge rain and melt water.

- Drainage. They are used in drainage systems near the foundation foundations, basement and basement floors.

- Bumpy. They are installed on highways and road junctions, where the curb is connected to the roadway.

- Sewer. Drains are discharged into sewer collector systems.

- Telescopic. Used for the construction of channels in the construction of tunnels, bridges.

- Edge

- Telescopic

- Drainage

The latter are also installed in areas with a large slope. They are usually made of heavy concrete, and sometimes reinforced with steel bars.

Sizes and volume

Concrete trays for stormwater are manufactured in more than 150 sizes. They are usually meter long. Their width can be from 14 to 400 cm, and height - from 6 to 168 cm.But according to the specifications, manufacturers can resize depending on the purpose of the gutter.

Volumes of standard trays vary from 0.07 to 0.3 cubic meters.

The throughput of the product is determined by its dimensions and depends on the standard value of the amount of precipitation.

Product labeling

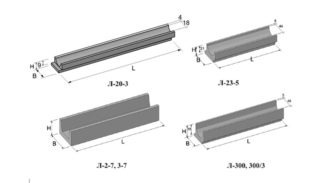

The standard labeling of the trays is the letter “L” and two digits. One of them shows the serial number (up to 38), the second shows the maximum load indicators in kN / m. But now on the market there are foreign products made according to the standards of other countries. They can be marked differently:

The standard labeling of the trays is the letter “L” and two digits. One of them shows the serial number (up to 38), the second shows the maximum load indicators in kN / m. But now on the market there are foreign products made according to the standards of other countries. They can be marked differently:

- DN is a value indicating how wide the tray is from the inside (in mm). If the numbers are two through a fraction, the second shows the depth of the gutter.

- L is the sectional length. It can be from half a meter to three meters, but the standard option is a meter. Occasionally there are very long trays - up to six meters.

- B is the width of the product outside. Depends on the internal value and wall thickness. The indicator can reach 190 cm.

- H is the height of the walls of the tray. Maximum - 150 cm.

Weight indicators are indicated depending on which metric system the country of manufacture uses.

Manufacturing Features and Materials

When creating concrete products, two techniques are used. This is vibrocasting or vibrocompression. In the first case, concrete is compacted during the pouring process by vibration. In the second, the parts are sealed with a special press. Such products are stronger, since possible cavities and air bubbles in the thickness of concrete are eliminated under pressure from the press. This eliminates the risk of internal splits.

To improve the resistance to stresses, special plasticizing substances and additives are added to the concrete mixture. Additives that involve air and are not afraid of sulfates make the trays resistant to temperature extremes, the negative effects of moisture.

Reinforced concrete trays are reinforced with steel bars and made of cement of grades no lower than M500. Products are durable, resistant to stress, but very heavy. Their weight can reach up to 2.5 tons. However, such trays are necessary in places with heavy traffic of heavy vehicles.

Instead of steel, fiberglass reinforcement or polypropylene fiber is now used. They give the necessary strength, increase anti-corrosion properties. Such a product weighs less than concrete products, but costs less. Thanks to the fibration, the shrinkage deformation is also reduced and the resistance to bending load is increased.

Despite the rather high cost, polymer concrete products are in demand. They are characterized by a mixed composition of concrete mortar and molten plastic. Such gutters are durable, durable and wear-resistant, not afraid of the effects of aggressive environments.

The simplest are small sidewalk trays (ebbs). They are created from a simple sand concrete mortar of low grades, without reinforcement or fibing. Such products weigh a little - up to 3 kg, but also do not last long.

Pros and cons of reinforced concrete products

The main advantages of LVK from reinforced concrete include:

- frost resistance;

- strength;

- resistance to significant loads and temperature jumps;

- anticorrosive properties;

- safety for human health and the environment;

- moisture resistance;

- budget price.

The ability to resist corrosion and other external influences increases the life of up to several tens of years. Products are not afraid of temperature fluctuations, which allows them to be installed in regions with any climate - in the far north and hot south.

Drainage products do not require special care - periodic cleaning of accumulated leaves and branches is enough. Products are made with a smooth surface, which contributes to the free passage of garbage.They can be installed on soft soils with highly located underground sources.

The disadvantage is the significant weight of the product. It increases the cost of transportation. Also, due to the severity of the gutters during installation, rental of special equipment is assumed. Because of this indicator, it is especially difficult to mount the chain chain on moving soils. However, a large mass for hydraulic drainage structures has an advantage: even a poorly fixed tray will never be washed away by a stream of water.

The cost depends on the size, technical parameters and strength. Prices for open concrete drainage trays start at 200 rubles, products with a cast-iron grate are more expensive - from 900 rubles. For comparison, polymer concrete trays cannot be found cheaper than for 1200 rubles. A product with steel reinforcement will cost from 3,500 rubles.

Mounting Features

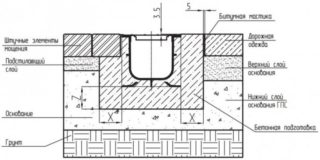

The installation of the gutters is almost the same for both private and industrial construction. Installation begins with the preparation of the required documents and the selection of suitable products.

The process itself includes the following steps:

- In accordance with the project, all the elements of the water disposal are marked.

- By marking, dig a ditch. The volume must exceed the dimensions of the structure that will be placed in it. The earth in the trench is carefully tamped so that the soil becomes dense. The location of the gutter should be 0.5 cm below the surface.

- At the bottom of the trench they lay and tamp a pillow of sand and gravel well.

- On the prepared base, the gutters themselves are installed taking into account the slope for the drain. For reliable fixation of products with each other, use the "tongue-groove" system, if one is provided, or simply fasten with hardware. Joints are treated with special sealant. If it is not, you can use acrylic compounds or bitumen.

After the installation of the drainage system is completed, voids are filled up on the sides with earth and begin to improve the territory. Lattices are mounted after completion of all work.

Installation of the drainage system can be performed on an existing coating or on a new one. To prevent clogging of the drainage system, it is recommended to clean it every two weeks.

Concrete gutters are used not only for drainage, but also for laying an electric cable, heating main equipment. However, it was the application in storm sewers that brought products to popularity.