Stone material is obtained by mixing and hardening the compacted mass, including a binder, filler and water. The proportions of concrete play a role in creating durability and the likelihood of not collapsing under compression. Special additives are introduced into the composition of the mixture in order to improve the properties of the material when used in various designs.

Concrete composition and special additives

In the production of sand, crushed stone, cement and water are mixed, the concentration of ingredients is determined by the brand of binding cement, aggregate size, sand quality. The concrete mass includes a number of water repellents, plasticizers. In the process of concreting, water and cement remain the main binding components of the mixture.

There are usual mixtures for civilian and industrial construction, special solutions for laying roads, erecting hydraulic structures, and thermal insulation devices. There are special formulations that resist high temperatures, chemical aggression, protect against radiation.

Concretes are subdivided in accordance with GOST 74.73 - 2010, GOST 25.192 - 2012 depending on various indicators:

- type of binder - slag, supercement, alkaline, alabaster, silicate compositions;

- structure - porous, dense mixtures, special consistency aggregates;

- strength conditions - hardening in the natural environment, during heat and moisture treatment, various pressures.

The proportion of cement and sand for concrete remains important. Additives give mixtures specific characteristics and properties.

Types of regulatory additives according to GOST 24.211 - 2008:

- plasticizers to reduce the volume of water, stabilizers to prevent delamination;

- mobility regulators for transportation over long distances;

- additives to increase frost resistance, corrosion resistance, water resistance;

- retarders to delay the start of setting;

- accelerators for quick hardening.

Components are introduced to increase the density, resistance to shock, abrasion of artificial stone. Photocatalytic components allow the solid material to self-clean from contamination and dust. The concrete formula involves the introduction of mineral ingredients to increase viscosity and pozzolanic activity.

Concrete Composition Requirements

The mixture is produced in factories or prepared at a construction site. In this case, the proportions of the concrete composition must be observed in order to produce a material with the required qualities. The main characteristics are the density of concrete and the amount of binder component.

The mixture is produced in factories or prepared at a construction site. In this case, the proportions of the concrete composition must be observed in order to produce a material with the required qualities. The main characteristics are the density of concrete and the amount of binder component.

By density, artificial stones are divided into types:

- especially heavy with a density of more than 2500 kg / m³;

- heavy - 2200 - 2500 kg / m³;

- lightweight - 1800 - 2200 kg / m³;

- light - 500 - 1800 kg / m³;

- especially light - less than 500 kg / m³.

The brand is assigned according to each area of application. The conditions of preparation and transportation over a distance, the circumstances of hardening are taken into account. The size of a large filler is selected, which is linked to the capacity of the concrete mixer, its type, dimensions of the product and the level of reinforcement.

Astringent ingredient affects the quality of the mixture:

- lean concrete is characterized by a low concentration of cement and an increased inclusion of crushed stone;

- fatty - high proportions of the binder and a small volume of large filler;

- commodity - the proportionality of the components is taken according to standard recommendations.

The filler in the mixture is up to 85% of the volume, it forms a solid skeleton, reduces shrinkage and prevents the appearance of cracks. It is necessary to have all the required parts for mixing concrete in a home concrete mixer and observe the dosage accuracy.

Composition and proportions of concrete for a bucket and for a concrete mixer

The proportionality of cement and water (W / C) is called the water-cement module, which is taken into account in the production of concrete mass. The lower the W / C ratio, the stronger the mixture. Theoretically, the ratio should be within 0.2, but such a dough has poor ductility and is inconvenient in operation. In practice, a batch is made with an index of 0.3 - 0.5.

Adding a large volume of water is a mistake in the proportion of concrete for the foundation or other construction. The mobility of the concrete mass is increased, but the compressive strength and density are reduced. The pores in the mixture appear as a result of the evaporation of excess moisture, which did not react with cement during the hardening process. Water does not fully react if cementitious cement is not sufficient.

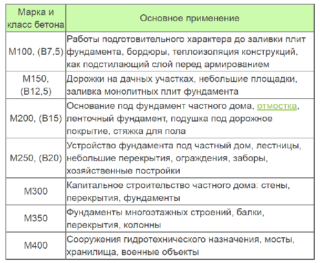

Grades of concrete stone are determined taking into account the compressive strength, which is determined by testing standard cubes of frozen material with a size of 200 x 200 mm. The brands M600, M500, M400, M300, M150, M100 and less are accepted. Concrete shows different reliability depending on the stone filler (crushed stone, slag, gravel, expanded clay aggregate) and on the characteristics of cement.

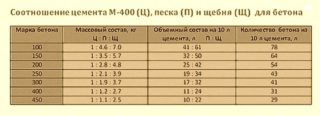

Cement M400

When using a binder of this brand for the manufacture of concrete M200, a proportion of 1: 3: 5: 0.5 is taken, where in order the portions of cement, sand, filler and liquid are indicated.

When using a binder of this brand for the manufacture of concrete M200, a proportion of 1: 3: 5: 0.5 is taken, where in order the portions of cement, sand, filler and liquid are indicated.

If you take a household concrete mixer with a mixture volume of 110 l at the outlet, concrete preparation will require the number of components:

- cement - 18.5 kg;

- sand - 52 kg;

- crushed stone - 115.7 kg;

- water - 5.8 liters.

It is better to use natural sand of medium and large size. Clay sand is limited. A small amount of clay particles reduces the strength of concrete. The sand is enriched during washing, mixing with imported high quality material.

Proportions of cement M400, sand and gravel to obtain different grades of concrete in a bucket (in kilograms):

- M100 - 1.0: 4.6: 7.0;

- M150 - 1.0: 3.6: 5.6;

- M200 - 1.0: 2.7: 4.9;

- M250 - 1.0: 2.3: 3.8;

- M300 - 1.0: 2.0: 3.5;

- M400 - 1.0: 1.3: 2.5.

Water is usually taken in half of the volume of cement. The brand of concrete depends on what will be built, for example, the foundation for the fence, blind area, screed or pole.

Mix the solution before use, in a volume that can be used in 2 hours.

Cement M500

The use of a binder of this brand with a similar proportion of 1: 3: 5: 0.5, where in order the portions of cement, sand, filler and water are indicated, gives the concrete brand M350.

The use of a binder of this brand with a similar proportion of 1: 3: 5: 0.5, where in order the portions of cement, sand, filler and water are indicated, gives the concrete brand M350.

To prepare the mixture in a concrete mixer with a finished mass output of 240 liters, the following components are taken:

- cement - 40.5 kg;

- sand - 113.8 kg;

- crushed stone - 235 kg;

- water - 12.65 liters.

Instead of sand, you can use the remains of metallurgy, mining, chemical industry. At home, it is difficult to make even M400 concrete, and it is better to order the M500 brand at the factory. Manufacturers sell dry water mixing kits at the site, but they must be taken from a trusted supplier.

The proportions of the concrete composition for the foundation of cement M500, sand and filler for the preparation of various grades of concrete in a bucket (in kilograms):

- M100 - 1.0: 5.8: 8.1;

- M150 - 1.0: 4.5: 6.7;

- M200 - 1.0: 3.5: 5.5;

- M250 - 1.0: 2.6: 4.4;

- M300 - 1.0: 2.4: 4.4;

- M400 - 1.0: 1.7: 3.3.

The ratio is correct for concrete that is laid on a dense surface. The porous base sucks moisture from the mixture, so the solidified mass is 1.5 times stronger.

Basic rules and recommendations for mixing concrete

The mixture is carefully compacted during manufacture and installation, and proportions are observed. The air is expelled from the gaps, and the cement milk is redistributed for tight adhesion with the solid aggregate. Manual electric vibrators are used when casting monolithic sections, and vibration tables are used in the manufacture of reinforced concrete and concrete blocks (slabs, crossbars, beams).

Waterproofing is carried out in 2 stages:

- strengthening additives are added to the composition;

- finished structures are covered with a waterproof layer of penetrating action.

Components that resist corrosion are introduced into the mass. Such a form of construction and location is selected so that the finished product is less subjected to cleavage, bending and other types of fracture, and perceives only the compression load.

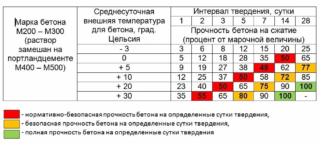

In winter, concrete warms up at the construction site after being laid into the formwork. In frost, the interaction of water and cement is weakened, the mass does not gain strength. After defrosting, such products may break up into individual components. To warm up, electrodes are inserted into the mass through which an electric current passes.

Features of concrete mixtures

The concrete class is set according to compressive strength. The cube is tested by compression and in 95 cases it is destroyed by a single load, which is taken as the limit. The class is indicated by the letter B and numbers that indicate the magnitude of the boundary pressure in MPA (megapascals), for example, B25.

When designing, the age of the mixture is assigned, which corresponds to its tensile and compression strength along the central axis at a certain solidification time. Concrete brand with letter M and numbers from 50 to 1000 means tensile strength in kgf / m³.

Workability of the mixture means the settling time of the cone of the selected concrete sample and is an important indicator when concreting using a concrete pump:

- superhard - more than 50 sec .;

- hard - 5 - 50 sec .;

- mobile - less than 4 seconds.

Other indicators are bending strength, frost resistance, water resistance. Frost resistance is indicated by the letter F and the numbers 50 - 1000, which indicate the number of episodes of freezing and thawing to failure. Water resistance is shown by the letter W and the numbers 2 - 20, indicating the magnitude of the pressure that can withstand a cylindrical sample.

Concrete application

Artificial stone is used in different directions of construction, depending on what proportions of components, cement and additives were laid in the production of the product.

Areas of application of brands for strength:

- manufacture of support foundation pillows - M100, M150;

- pouring monolithic screeds, bases, paths, retaining walls, blind area - M200;

- the device of monolithic strip foundations, slab bases, load-bearing elements, pavement coatings - M350;

- erection of structures of hydraulic structures, mines - M400 and M450;

- construction of structures with special requirements for quality, for example, dams, dams, metro stations - M500, M550.

In private construction, different types of concrete are used. For laying floors, warm types are taken using slag, expanded clay instead of crushed stone. Woodworking waste is used as a filler, chips, sawdust are used. Such mixtures have a lower mass and prevent overcooling of the room. Compositions are reinforced with a mesh when arranging entrances to the house, descents into the garage to reduce the effect of shear.

In capital construction, concrete is used for the construction of high-rise and low-rise houses, arches, bridges, domes, beams and pipes. The metal frame in piece plates, beams, girders expands the possibilities of using reinforced concrete products.