Not a single full-fledged plot of land can do without farm buildings (hozbloks). There are many different buildings, the most common of them is a barn. You can keep pets in it, store firewood or tools, you can equip a small workshop or store building materials. The main requirements that apply to this type of farm buildings are the stability of the structure and its durability. These characteristics depend on the correct laying of the foundation, the choice of which is largely determined by the composition of the soil and the features of future construction.

Types of soil

Before you begin laying the foundation for the shed, you need to determine the composition of the soil on the allocated land. There are several types of soil:

- rocky;

- sandy;

- gravel

- sandy loam and loam;

- clayey.

A site with rocky or gravel soil is the best option. Rocky soil does not freeze, and gravel can freeze by no more than 0.5 meters. These soils do not "float", do not compress and do not sag. Their only drawback is heavy handling. However, on such soils, the foundation for the hosblock does not require deep penetration.

Clay soil is considered unsuitable for construction. It exerts strong pressure on the base of the structure, subject to expansion and compression.

Least suitable for laying the foundation is soil consisting of sand, sandy loam and loam. Even with small frosts, it freezes to a great depth, and the formation of “quicksand” is also characteristic of it.

Typical foundations

When building hozblokov, you can use different types of foundations:

When building hozblokov, you can use different types of foundations:

- tape;

- columnar;

- monolithic (jellied) and its varieties - plate and floating;

- on driven piles (pile);

- pile-screw.

Such structures may be finely or heavily buried. The barn is considered a lightweight structure, therefore, during its construction, a shallow base is most often laid, the depth of which depends on the depth of freezing of the soil and averages 0.6 m.

Strip foundation

The strip foundation is most often used in suburban construction. It is a monolithic or prefabricated strip running along the entire perimeter of the structure. On this strip, then all the walls of the structure are erected. If the shed is built of heavy materials, under the foundation it is necessary to provide a sand and gravel cushion covered with waterproofing. The depth of the bookmark depends on the composition of the soil and the weight of the structure.

Column foundation

The column foundation is used in the construction of structures of lightweight construction (frame, panel, etc.). It is based on massive pillars made of brick, concrete or stone. Pillars are located in places of increased loads and in the corners of the structure. On soft soils, the posts are extended to the bottom, which allows you to distribute and reduce the load on the soil. The posts are interconnected by a grillage (frame). The space between them is filled with crushed stone and covered with a layer of concrete. The columnar foundation for the barn is not recommended to be erected on heaving soils. In addition, depending on the type of soil, the foundation may need a sand cushion.

Monolithic foundation

The monolithic foundation is a reinforced concrete slab laid on a layer of crushed stone. Pour the slab under the barn directly on the spot, it is not necessary to deepen it. All load-bearing elements of the erected structure are installed on this plate.It can be displaced along with the structure, thereby compensating for soil vibrations (floating foundation). Waterproofing for such a foundation is a prerequisite. The foundation can be used in the construction of structures on heaving and landing soils with weak bearing properties.

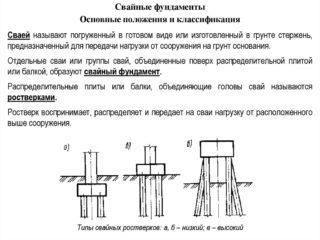

Pile foundation

The basis of the construction of the pile foundation laid piles (columns), buried in the soil to solid soil layers. When erecting a barn on piles with their own hands, its upper part is connected among themselves by beams or blocks (foam blocks, etc.). Pile structures are used in conditions of:

The basis of the construction of the pile foundation laid piles (columns), buried in the soil to solid soil layers. When erecting a barn on piles with their own hands, its upper part is connected among themselves by beams or blocks (foam blocks, etc.). Pile structures are used in conditions of:

- unstable and heaving soils;

- high water table;

- marshland;

- uneven terrain.

Pile screw foundation

A screw pile is a steel pipe with a spiral blade around the trunk. This pile is screwed deep into the ground, which makes it possible to compact the soil at its base (underground). The upper part of the piles is cut at the same level and poured with concrete. Such structures are laid on swampy, peat or flooded soils. They are used in the construction of lightweight (frame, wooden, etc.) buildings in a complex landscape.

The advantage of a pile-screw foundation is that it can be built at any time of the year.

Concrete mortar for pouring the foundation

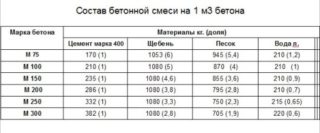

Starting to lay the foundation under the do-it-yourself hoblock, you need to prepare a concrete solution, which includes cement, sand, gravel and water. The durability of the whole structure depends on the quality of its preparation. To make the solution tenacious, you need to mix crushed stone and sand in a ratio of 5: 3, add 1 part Portland cement grade M-400 and fill everything with water. As a result of mixing, a dense homogeneous mass should be obtained.

Starting to lay the foundation under the do-it-yourself hoblock, you need to prepare a concrete solution, which includes cement, sand, gravel and water. The durability of the whole structure depends on the quality of its preparation. To make the solution tenacious, you need to mix crushed stone and sand in a ratio of 5: 3, add 1 part Portland cement grade M-400 and fill everything with water. As a result of mixing, a dense homogeneous mass should be obtained.

When preparing the solution, crushed stone of different fractions should be used - from large to small. Crushed stone, sand and water should be clean, free of debris and any impurities. Cement should be fresh.

The technology of building the foundation under the barn

When erecting sheds, they often lay a strip foundation. It can be used for all types of soil and for almost any structure. It gives the opportunity to equip the basement.

When erecting sheds, they often lay a strip foundation. It can be used for all types of soil and for almost any structure. It gives the opportunity to equip the basement.

The laying of the strip foundation begins with digging a trench. Its depth should be 15 cm higher than the depth of freezing in the coldest time of the year. The width of the trench should be about 70 cm, which will make it possible to obtain a foundation foundation (strip) of 40 cm wide. Crushed stone is poured onto the bottom of the trench, the layer of which should be at least 10 cm after careful tamping. After that, the compacted crushed stone is covered with a 5-centimeter layer of sand.

Then, a formwork is installed in the trench, protruding above the edge of the trench by about 20-30 cm, which will raise the building above ground level and protect its walls from getting wet.

To strengthen the entire structure, it is recommended to lay a mesh of reinforcement in the trench. In this case, the diameter of the reinforcement should be about 12 mm, and the mesh size should be about 30x30 cm.

The prepared solution is poured into the trench along the upper edge of the formwork and allowed to solidify well. Next, the formwork is removed from the trench, the formed cracks are covered with earth and well packed.

A waterproofing layer is laid under the shed on top of the foundation, which will separate it from the base of the building.