The brand of concrete mix characterizes quality when choosing a composition. The material has other indicators: ductility, resistance to moisture, frost. The concrete brand for the foundation indicates the ultimate compressive strength of the set stone, after which it is destroyed. Bulk components are mixed and shut with water in a certain ratio.

General concepts and specifications

Foundation concrete is lean, salable and greasy. In the first form, there is a lot of filler in the form of crushed stone, cinder block, but little cement. Ready-mixed concrete is made in a standard proportion, and in the oily variety, the content of large stones decreases and the volume of the binder increases.

The density of concrete is from 500 to 2500 kg / m3, depending on this mixture are divided into types:

- especially heavy;

- heavy;

- lightweight;

- lungs;

- especially light.

Water resistance is indicated by the letter W and one of the numbers: 2, 4, 6, 8, 12. The indicator indicates the ability of concrete to resist moisture. A material with a high rate is used as concrete for the foundation, monolithic slabs, basement, blocks, because it is in contact with soil water.

Frost resistance is indicated by the letter F and the number 50, 100, 150, 200, 300. The indicator is important for construction in the northern regions, because it determines the ability of the material to withstand repeated freezing and thawing in the natural environment.

Concrete grades for the foundation

The strength of concrete increases during the hardening process. After setting the next day, it is immediately 50%, but the mixture gets the required 100% only after 28 days. Strength is determined by the ratio of liquid and cement in the composition, which is called the water-cement module (W / C). A concentration of 0.2 is considered ideal, but such a solution is difficult to stack and its ductility is low. In practice, a ratio of 0.3 to 0.5 can be made.

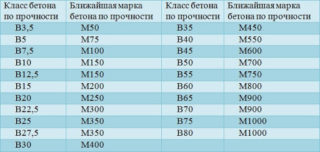

Distinguish the brand of concrete and its class. The mark is indicated by the letter M and a number that shows the tensile strength of the hardened mixture by the compressive force in kg / cm2. The class shows the load that the sample can withstand before failure, but is expressed in MPa (megapascals).

Conformity of grades and classes of concrete:

- M 100 - B 7.5;

- M 150 - B 12.5;

- M 200 - B 15;

- M 250 - B 20;

- M 350 - B 25;

- M 400 - B 30;

- M 450 - B 35;

- M 550 - B 40.

Almost always, the brand depends on the volume of cement in the composition. An increase in the amount of binder leads to an acceleration of solidification, therefore, additives are required that extend this period. Strength is checked in the laboratory when testing a hardened sample with dimensions of 0.2 x 0.2 m.

Tape

M 100 is a lean solution, it can be poured with the support pillows under monolithic bases. The concrete brand for the strip foundation is used above: M 150, M 200, M 250, M 300. From this concrete, the foundation is poured under a brick garage, a fence, a one-story or two-story house from expanded clay block, wooden beam or logs.

M 300 and M 350 are used for support bases on unstable soils. Pile and pile-grill foundations, ceilings of buildings are made of such concrete, walls are erected. To increase the strength, concrete is reinforced with a three-dimensional frame or flat mesh, depending on the application.

M 450 and M 550 are used in the construction of foundations, to which special requirements apply, they work in conditions of high humidity or in permafrost regions. Such bases include retaining structures of hydraulic structures, bridge supports, extremely loaded piles, beams.

Tiled

The base in the form of a plate can be monolithic or precast. In the first case, the concrete mass is poured into the formwork, and in the second, ready-made slabs made at the factory are used. At a construction site, the composition M 200, M 250 is kneaded to make the bulk of the slab.Before the device of the slab support, a foundation pillow is created from sand, gravel, which is concreted with lean concrete M 100.

At the precast concrete factory, slabs are also poured from the M 200 and M 250 brands. The laid and reinforced slab is placed on vibration tables to get rid of excess air bubbles. Concrete vibrate manually in a construction site.

Slabs of mortar M 300, M 350 are used if the building is being erected on frozen ground, quicksand, clay or swampy soils. Special anti-moisture additives are added to the mixture before solidification. The structure is covered with a waterproofing compound, which is absorbed and additionally protects the slab from the effects of soil fluid.

For the blind area

For the protective strip around the house, concrete is used for the blind area of the M 150 brand. A similar composition is used for garden paths and walkways to outbuildings. The width of the blind area is calculated taking into account the protrusion of the roof overhang, but is standardly taken at the level of 1.0 meters.

Before laying the concrete mortar, a layer of clay is made to reduce the possibility of moisture penetrating to the foundation. Additives are added to concrete to increase resistance to rain and atmospheric moisture. The appearance of transverse and longitudinal cracks in the thickness of the blind area is not allowed. The thickness of the concrete is 7 - 10 cm.

Rules and criteria for choosing a concrete brand for the foundation

The characteristics of a certain class are regulated by norms, standards, are prescribed in the technical specifications of TU. For each brand, process maps are developed taking into account building rules.

To determine which brand of concrete to use for the foundation, several factors of influence must be taken into account:

- total load of the building on the base;

- soil properties and description;

- climatic indicators in a given geodetic region;

- the presence of a basement, a garage in the underground part;

- type of foundation (strip, slab, pile).

The usual type of ready-mixed concrete M150, M 200, M 250 is used for regular and industrial construction in normal conditions. There are special solutions with enhanced resistance to high temperatures, protection against background radiation. Compositions with a porous filler in the form of slag, expanded clay, sawdust are used to reduce heat loss through the base.

Taking into account the load

The collection of loads on the foundation is done by professional designers. The owner of the house can approximately calculate the weight of the house, but it will not be easy to determine the effect of snow or wind force taking into account the windage of the roof. For this, many tables with specific coefficients are used.

The collection of loads on the foundation is done by professional designers. The owner of the house can approximately calculate the weight of the house, but it will not be easy to determine the effect of snow or wind force taking into account the windage of the roof. For this, many tables with specific coefficients are used.

Determine what concrete is needed for the foundation of the house by calculating the total weight of the building and the current loads:

- The weight of the walls. The volume of the enclosing structures is calculated and multiplied by the volumetric weight of the material. Aperture beams, ledges, bay windows, loggias and balconies are taken into account.

- The weight of the floors. The weight of the beams, girders, girders is calculated, the mass of the floor and floor material is added.

- Coating weight. The load from the roof structure, rafters, lathing, roofing is summarized.

- Constant load. It takes into account equipment, furniture, people, communications.

- Temporary load. The weight of the snow is calculated, the pressure of the wind is taken into account.

Recommendations regarding the choice of brand are given in the project of the house, so the user most often needs to take a class from the technical documentation for the construction.

According to soil properties

Soil characteristics at the site of construction of the object are taken into account for the right choice. Important properties include heaving of the soil, which indicates the deformation and shear of the layers when the season changes. Bloating depends on the composition of the earth's layer.

Soil characteristics at the site of construction of the object are taken into account for the right choice. Important properties include heaving of the soil, which indicates the deformation and shear of the layers when the season changes. Bloating depends on the composition of the earth's layer.

Rocky and sandy soils belong to the category with weak heaving properties; they differ in a homogeneous structure; therefore, they evenly disperse efforts along the foundation body.On stable lands, the M 200 brand is used.

Clay soil and loam strongly swell in spring with warming and in case of frost. In the cold, clay increases in volume. The layers swell unevenly due to uneven soil moisture. For the foundation on unstable types of soil, the brand M 300 and M 400 are used.

By design of the base

The brand of concrete used depends on the type of foundation, for example, a basement, a basement garage, an underground cellar or a monolithic slab are being built. In the latter embodiment, it is important whether such a base is heated or made in the form of a cold support.

The mark of the standing of soil waters in the spring and the depth of freezing of the earth plays a role. The water resistance of concrete of the M 200 brand is lower than that of the composition of M 350, so the benefit of the latter cannot be overestimated. To save money, the M 200 is used, but external insulation from moisture from the roofing material is done on a special mastic.

The pile foundations are pointed by a stable soil layer, therefore, the calculation relates to the laying depth of columnar supports. For such structures, a brand of at least M 350 is used, and the grillage is made with M 300 concrete. Several options are calculated to find a good option in terms of efficiency, bearing capacity and water resistance.

Concrete production

Water in the concrete mixture is taken from ½ of the volume from the same indicator of cement. There is always a desire to add more water to increase ductility. But the excess liquid does not react with cement and remains in the form of uncompensated sections. During hardening, water evaporates through the thickness of the concrete and voids form in its place, which affect the strength index.

The standard ratio of concrete: 1: 3: 5: 0.5, where the components are distributed according to: cement, sand, gravel, water (in volume ratio). With cement of grade M 400, with this proportion, concrete grade M 200 is obtained, but if cement M 500 is used, then with this composition concrete M 350 will be obtained.

Calculation of the amount of solution

The foundation of any design is divided into sections that have geometric dimensions to calculate the volume. The cubature of disparate elements is added up and the total volume is obtained.

The foundation of any design is divided into sections that have geometric dimensions to calculate the volume. The cubature of disparate elements is added up and the total volume is obtained.

Concreting of 15.2 m³ (strip foundation) requires 9.5 parts of components (1: 3: 5: 0.5). Divide 15.2 / 9.5 = 1.6 m³, where:

- cement - 1 part = 1.6 m3 x 1.6 (volumetric weight of cement) = 2.56 tons (52 bags of 50 kg or 103 bags of 25 kg);

- sand - 3 parts = 1.6 m3 x 3 x 1.5 (volumetric weight of sand) = 7.2 t, KAMAZ can be ordered

- crushed stone - 5 parts = 1.6m3 5 x 2.1 (volumetric weight of crushed stone) = 16.8 tons (to buy in bulk).

Each specific option is calculated, while taking into account the location of the structure. The foundation is designed so that there are less shear and bending loads, and only compression or tension acts. Concrete works more efficiently for such efforts.