A walkway of pavers or asphalt, located around the house, is not just an element of the landscape, but a functional design. The purpose of the blind area is to protect the foundation from the negative effects of the external environment. It is not difficult to make it, so house owners often arrange the construction on their own.

What is the blind area

The blind area is a covering along the perimeter of a building, necessary for water drainage. The design is made of waterproof material. It is of two types:

- hard - waterproof monolithic coating of concrete or asphalt;

- soft - a protective tape made from bulk materials (gravel, gravel) or tiles; moisture is removed using an internal waterproofing layer.

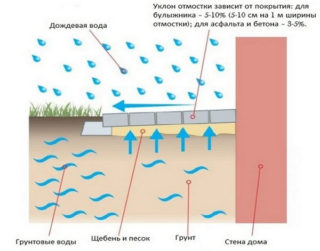

The blind area is not limited to the top decorative coating. Under it is heat and waterproofing, as well as backfill, which protects the foundation from heaving of the soil.

The need for blind areas and requirements for it

One of the elements of comprehensive building protection is a perimeter drainage cover. It is necessary to protect the foundation and basement from rainfall and flood waters. During rain, water flows down the roof and falls on the area near the walls. The soil is gradually eroded and sags. The base of the house loses strength due to constant contact with moisture. In winter, the freezing of water that has penetrated the foundation and basement leads to masonry rupture and cracking. Damage reduces the structural bearing capacity.

In addition to the main protective function, the coating performs other tasks:

- Additional thermal insulation of the base of the building. When creating the blind area, a layer of insulation is part of the common pie. This helps prevent freezing of the soil, improve the thermal insulation of the basement and basement.

- Decorative function - the blind area of decorative tiles, natural stone or cobblestones is used as an element of landscape design. Material in structure and color is selected in harmony with the facade of the house. A neat tape around the perimeter gives the building a finished look. Sufficient cover width allows you to use it as a track.

- Barrier from swelling of the soil - the structure goes 40-50 cm deep, being a barrier around the foundation. It evenly distributes the deformation effect of the soil resulting from seasonal freezing.

The device blind areas regulate the building requirements for the foundations of buildings. By standards, its width depends on the type of soil and the size of the overhang of the roof. The average figure is 100 cm, but can be increased to meet the recommendations of specialists. The size of the coating should exceed the size of the roof overhang by 15-20 cm. The advice is not relevant if a competent spillway system is arranged. Rainfall from the roof goes down the drain and falls into a storm sewer. For sandy soil, the width of the concrete strip can be reduced to 70 cm, on clay soil it should remain at least 1-1.2 m.

The second important criterion is the angle of inclination. According to the standards, it is 1-10 °. The slope value is selected based on the amount of precipitation in the region, the design features of the coating. If it serves as a track, then you should not exceed an angle of 3 °, otherwise it will be dangerous to move along ice in it. The slope should be from the wall, in which case the water will drain into the drainage or storm trays.The material of the blind area is also important - crushed stone, tile, pavers require a slope of 5%, concrete tape - within 3-5%. According to the rules, the outer edge of the structure should protrude 5 cm above the ground.

The length of the protective coating is not regulated, but it must be continuous and cover the entire perimeter of the house. The thickness of the blind areas according to SNiP is:

- sand - 10-15 cm;

- crushed stone - 6-10 cm;

- concrete - 7-12 cm.

The size of the layer of bulk materials is given in a compacted form. To create a frost-resistant concrete coating, cement of the M400 or M500 brand will be required. The sand should be clean, free from impurities. The size of the crushed stone fraction is 30–40 mm.

In areas with strong stable soil, the blind area for the pile foundation can not be arranged. It is enough to organize the correct drainage of rain and melt water. An internal or external drainage system is being constructed with drainage pipes directing the water to the storm sewer.

Design Varieties

To protect the foundation, several types of blind areas are used. They differ in design features, materials and manufacturing technology. Any design consists of internal bulk layers and an external coating. The protective tape is hard and soft.

Concrete paving

The material meets all the requirements of frost resistance and moisture resistance, has high mechanical strength. The thickness of the elements is 6-8 cm. They are classic rectangular or curly. It is easy to work with paving stones; a home master can lay it, following the technology. Concrete products are installed on compacted layers of sand and gravel. Before the layout, a drawing (diagram) of the future coating is made. On the edge of the track place a side. Paving stones can be tamped with a vibrator, seams sprinkled with sand.

Made of stone pavers

The blind area of the building made of pavers is a beautiful landscape solution. The material for it is granite, basalt, in some cases sandstone. The geometric shape of the parts can be different, usually sawn stone, less often chipped. The texture and color is selected in accordance with the architectural features of the basement. Stone paving is more durable and more reliable than concrete products. She is not afraid of temperature spikes, moisture, mechanical stress.

From paving slabs

The blind area around the house made of paving slabs is an attractive design with a long service life. Piece elements are made in two ways: casting and vibropressing. Vibrocast tiles are attractive in appearance; they are made in various colors and shapes. Its minus is insufficient strength. Vibro-pressed products are made in a simple form and muted shades, but they are much stronger. The coating is laid on the base of sand and gravel. To exclude horizontal movements, a curb of concrete slabs is installed.

From crushed stone

A soft blind area made of gravel is a budget option that does not require much effort when installing. The basis of the bedding is clay. To create a waterproofing, you will need to buy a plastic film or other canvas. Sand is poured on top of it, at the same time a slope is formed. Next is the geotextile, part of which is wound on the wall. Finishing filling is carried out with crushed stone of the middle fraction (30-40 mm). The blind area made of gravel around the house is made on movable heaving soils. The soft structure is not affected by soil movements.

Concrete structure

The device of a rigid blind area made of concrete requires a lot of effort and time, but the result is a coating that preserves the integrity of decades. The clay or clay and sand serves as the bedding for it. The design on heaving soil requires reinforcement with a metal mesh. Concrete mixture is poured into the formwork installed around the perimeter of the house.So that when expanding the material does not crack, leave expansion joints every 3 m of concrete tape and along the base. It takes 4 weeks to gain strength.

Tools and styling technology

With an independent device, the blind areas will need not only to buy material, but also to prepare the necessary tools:

- bayonet shovel and pickaxe for earthwork;

- cord, measuring tape and pegs for marking;

- construction mixer and buckets or concrete mixer;

- hammer;

- building level;

- spatulas;

- mallet.

The step-by-step installation instructions for the concrete blind area include the following items:

- Land marking. From the wall of the house measure 70-120 cm and drive in pegs around the perimeter. A cord is pulled between the stakes. The marking shows the outer boundary of the structure.

- Excavation. The next step is excavation. A trench up to 50 cm deep is dug with a pick and shovel. When choosing soil, the bottom is made with a slope of 2-3 cm from the wall.

- Waterproofing - the bottom of the trench is rammed with clay, which will serve as a hydraulic lock. It is covered with roofing material, a thick plastic film or a special membrane. One of the edges lead to the wall. Waterproofing is laid with overlapping adjacent paintings.

- Sanding rammer - a layer of clean sand is poured and carefully rammed. Its height should be 10-20 cm, depending on the depth of the ditch. Then a layer of crushed stone is poured up to 10 cm. The mixed fractions are taken.

- Thermal insulation. For warming, the blind areas use rigid polystyrene foam boards. It is laid on a sand pillow. Sheets with a thickness of 50 mm are laid in two layers with overlapping seams. This prevents the appearance of bridges of cold.

- Formwork and reinforcement. For concrete construction, formwork is assembled from boards with a thickness of 20-30 mm. They are fastened with nails or bolts. Reinforcement is carried out using a grid with 100 mm cells or a strapping frame made of reinforcement. Every 22-2.5 m between the grid, wooden slats are laid, which will indicate the damper seams.

- Concreting. A mixture of Portland cement grade M400, sand and gravel is used as a fill. The mixture is prepared in portions and poured into the formwork. It should evenly fill the frame without leaving voids. On the formwork, the solution is leveled by the rule. To release air in several places, concrete is pierced with a rod. To increase the strength of the coating, the surface is sprinkled with dry cement with a layer of 2 mm. Concrete should dry for 28-30 days. For uniform evaporation of moisture, the surface is covered with polyethylene.

Ceramic tiles or pavers laid on top will give an aesthetic appearance to the gray concrete coating.

Advantages and disadvantages

Before choosing the type of blind area, you should weigh the pros and cons.

Advantages of soft construction:

- lack of shrinkage;

- resistance to temperature fluctuations and soil heaving;

- when using paving stones and tiles, an attractive architectural element is obtained;

- simplicity of the device.

Disadvantages:

- sprouting grass;

- pollution of the embankment from rubble or gravel.

Rigid construction advantages:

- asphalt or concrete tape is highly durable;

- durability of operation;

- water resistant.

Disadvantages:

- for any deviations in the technology of laying layers or pouring concrete, cracks may occur;

- the coating is not decorative;

- laborious and long work.

If there is not enough data to assess the construction conditions, consult a professional.

Common mistakes when creating your own coating

The rush during the installation of the protective structure or the lack of information about the laying technology leads to problems with the operation of the blind area. Among the most common errors:

- Insufficient width - a narrow strip will not prevent erosion of the soil by water falling from the roof during rain.

- Small slope - a lack leads to stagnation of moisture on the coating. Excessive tilt is also dangerous, it makes it difficult to walk on the surface.

- Lack of expansion joints - soil movement and natural expansion of concrete when heated without embedded expansion joints lead to structural failure. Seams are left between the blind area and the outer part of the basement, as well as across the concrete strip itself.

- Insufficient size or unevenness of the sand-gravel cushion - poorly tamped layers shrink. A soft construction can damage the waterproofing layer, and cracks will appear on the surface of the concrete coating.

- The use of sand mixed with clay - contaminated components degrade the quality of the concrete mortar. Its durability and operating time are reduced.

- Are there grooves for drainage of water or drainage? The water drainage from the building will not be effective if it does not fall into a special drainage system. On it, moisture should go into a storm sewer or simply be diverted away from the building.

The blind area around the house is a quality protection of the foundation from destruction. The coating of decorative materials makes the functional design a winning element of the landscape.