The foundation perceives the loads from the building and evenly distributes the forces on the base. The foundation for the fence will protect the fence from distortions, tears and deformations. The base is a concrete strip with square extensions under the pillars of brick or concrete. Metal racks do not require an increase in the size of the support strip.

The need for a foundation for the fence

A solid base is an integral part of the fence, especially if the fence is heavy. The judicious use of the material involves the construction of a foundation in accordance with the needs. For example, metal racks with a grid require pouring only under the pillars, and a continuous concrete tape will cause overruns.

The support in the earth will become irreplaceable in such cases:

- on the construction site is unstable soil;

- the fence is installed near a river or other reservoir;

- strong winds are observed in the area, the house is in an open area.

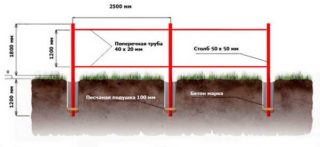

Under the brick pillars of the fence, the base is made wider in the plane and deepened in comparison with the concrete tape. A similarity of a pile is made, the base of which stands 20 cm below the main strip. For a fence on a strip foundation, a trench 20 cm wide is made with a depth of 50 cm. Under the posts, the section in the plan is 40 x 40 cm and the depth increases to 70 cm.

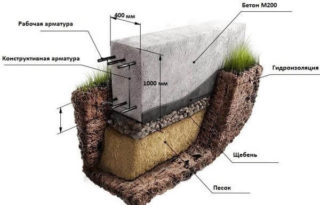

The foundation is reinforced with a frame with rods with a thickness of 8 - 10 mm. For the cross members, 6 mm rolled metal is taken, the jumpers are set in increments of 40 cm. The joints of the reinforcement are welded, connected by knitting wire or plastic clips. The door supports are connected to the frame from the reinforcement in the foundation body.

Parameters affecting the depth of the foundation

The indicator affects the uniformity of the load distribution, prevents the shift and deformation of the base itself and the fence. Depth value means the distance from the top of the foundation to its sole. The tape base is laid in steps, if a large surface slope with a vertical drop is observed on the site. The upper part of the support should protrude 10 cm from the soil so that dirt and precipitation do not accumulate on top during bad weather.

The indicator affects the uniformity of the load distribution, prevents the shift and deformation of the base itself and the fence. Depth value means the distance from the top of the foundation to its sole. The tape base is laid in steps, if a large surface slope with a vertical drop is observed on the site. The upper part of the support should protrude 10 cm from the soil so that dirt and precipitation do not accumulate on top during bad weather.

Depth of laying is determined taking into account factors:

- design feature of the fence;

- fence weight and load size;

- land relief and soil category;

- ground moisture standing height;

- freezing mark in winter.

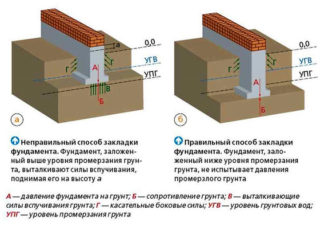

Under sections of corrugated board between heavy posts, the laying depth is reduced, and under the basic elements, a concrete tape under the fence is made lower. This method saves resources and reduces labor costs during excavation and concreting. The freezing index is determined by the type of soil in the special tables of the construction area.

The base is buried 30 to 40 cm below this indicator for massive barriers made entirely of brick or concrete, while the width of the support should not be less than the width of the wall. The freezing mark is not taken into account during construction on rocks, in which case the foundation is deepened by the size of the immersion columns (50 - 70 cm).

Types of foundation for the fence

The type of support depends on the material of the fence. Columnar and monolithic foundations are used in different cases, depending on the severity of the fence.Correct calculation along with high-quality materials will lead to the creation of a solid foundation and a long service life of the fence.

The choice of design is affected by:

- uniformity of the structure of the fence in plan;

- the presence of massive pillars;

- soil stability and moisture.

Insufficient height or width of the base will not allow you to withstand the effort, so the fence can fall after a frosty winter. The base sags due to its mass, soil shifts under loads, cracking as a result of freezing and thawing cycles (if the freezing depth is not taken into account).

The basis is:

- columnar;

- monolithic;

- from masonry;

- tape type.

A different form of the foundation allows you to find the best way to counter negative factors and maintain the integrity of the fence. Concreted tapes are continuous and intermittent, and prefabricated prefabricated glasses are used under the gate posts and columns. A prerequisite is welding of outlets with a reinforcing frame of a monolithic section. Builders save material using combined designs.

Pillar fill

Pillars are exposed at a distance of 1 - 4 m, square holes are dug under them to a depth of 0.8 - 1.2 m. At the bottom, filling is made of compacted sand, gravel or gravel. For strength, a volumetric metal frame is made of reinforcement, in the center of which a supporting element of the fence is placed. The verticality of the installation is checked using a plumb line in perpendicular planes.

Concrete is poured in layers between the elements; each layer is vibrated by an electric tool. Air bubbles weaken the concrete mass, so they need to be expelled from the solution. If the fence is made of corrugated board, the posts are placed after 2 m, because the material has high windage and the wind load increases.

The positive sides of the columnar base under the fence:

- profitability - the solution is laid only in places of support racks, and not along the entire length of the fence;

- ease of installation - no skilled workers required;

- Duration of operation - pillars are not destroyed and serve up to 30 years.

The columnar base is made for fences made of netting, wooden grating, picket fence, metal profile, siding. Work well in clay soils. The bottom (heel) can be expanded if the soil belongs to the heaving category.

Monolithic fill

This design includes the simultaneous operation of the posts together with the concrete base. The option is used for heavy fences made of monolithic concrete, brick, natural stone, which are built on swampy lands, in permafrost or quicksand. The combined action of the tape and poles, filled at the same time, can withstand the loads from the wall, wind forces, the weight of the supporting poles, prevents soil shifts.

To build such a foundation for the fence, follow the step by step instructions:

- A common tape trench is dug to a depth of 50 cm around the perimeter in accordance with the diagram and drawing. The width is determined in accordance with the transverse size of the fence.

- The position of the fence posts is marked, and soil is dug up for deepening. The size of the pit is 40 x 40 cm, and the step of the supports is taken 1 - 2.5 m. The earth is taken out by 1.5 meters.

- A sand and gravel pillow is made. The posts are installed in pits and concreted 2/3.

- The reinforcing mesh is laid in the longitudinal trenches. If necessary, formwork is made or pouring takes place directly into the ground.

To prevent moisture from leaving concrete in wood or earth, lay a film on the sides of the trench. Formwork is needed if the base is 10 cm above the ground surface.

Stone foundation

The bottom of the fence made of natural stone looks advantageous in combination with high-quality materials, such as forged bars, carved wood.For a fence made of light corrugated board, such a base is not used. The stone belt is the base of the fence, which rises 0.7 - 1.0 m above ground level. Such a foundation does not penetrate into the ground.

The laying perimeter is pre-aligned, boulders are used, reinforcement for the bundle is placed inside the masonry. Metal rods or other embedded parts are vertically installed in the body of the stone base for the subsequent fastening of the upper fence. A solid foundation can be made with one's own hand if one is familiar with such work.

The stones have different dimensions and shapes, so attention is paid to the joints of the elements. Large parts are combined with small parts so that voids are not created. The stones are placed on a cement-sand mortar, concentration 1: 3 (cement, sand, respectively). The masonry mass is immediately removed from the surface of the stone, otherwise after adhesion it is difficult to remove from an uneven area. Elements turn with their attractive side outwards if the interior of the fence is not particularly important.

Tape base

A common option in the form of a concrete tape is performed under the perimeter of the fence. The base is easily done with your own hands, if there is little experience with concrete and excavation. It is a tape base for massive and heavy fence designs. The depth of laying is determined by the type of soil. A reinforcing cage is placed in the body of the tape, without which the foundation will crack after the first winter.

The tape base is carried out:

- finely buried;

- buried.

The first option is built in soil with stable characteristics. The second variety is intended for unstable soils, but rarely goes deeper than 0.7 m, even if the fence with a strip foundation is of great height. The design of the tape may be monolithic or contain prefabricated reinforced concrete blocks.

Advantages of the tape type:

- ease of construction - no special equipment is needed, marking is done manually, like digging a trench, preparing concrete and pouring;

- low construction cost - simple materials are used, the dimensions do not imply an overspending of cement, sand, gravel and metal;

- foundation production speed - together with the trench digging, the period takes no more than 4-6 days.

The tape base is made for fencing of various materials that have weight or strong windage.

DIY construction technology

Before starting the construction of the foundation, it is necessary to calculate and draw the elements of the fence. Sheets of corrugated board, slate have dimensions that are taken into account when marking the supports. Columnar foundations are made in the recesses of trenches in strictly defined places, so it will subsequently be too late to redo the structure of the fence taking into account errors.

For foundations, concrete of the M300 or M200 brand is made, such a composition is recommended by specialists for the foundation under the fence. The protruding top of the base is painted in a suitable or contrasting color compared to filling the fence. Such a foundation is decorated with tiles, ceramics, natural materials.

Step-by-step instruction

The ditch digs manually or using an excavator. In the second option, you will have to do a bottom cleaning and align the longitudinal walls after the machine is running. A layer of crushed stone and sand is laid with a thickness of 10 - 15 cm, which is spilled with water and rammed with hand tools.

Instructions for the device:

- Formwork is made of boards or sheets of particleboard, OSB with impregnation. You can use improvised materials, for example, door leafs, sheets of flat slate, furniture panels. Shields are fastened together and fixed to the frame. On the outside, stops and braces are placed so that the concrete does not ruin the structure.

- A bulk frame made of metal rods is placed in the formwork; for longitudinal elements, you can use a corner, a strip. Elements are joined by welding or viscous.For lightweight fences, you can use flat longitudinal mesh of reinforcement.

- Concreting is done in layers. If it is necessary to leave the work front for tomorrow, a safe rabra (a kind of ladder) is performed at the site of the future joint, since there should not be vertical seams. A vibrator is used after each installation to get rid of the air inside.

In summer, the top of the foundation on the second day is covered with a layer of sawdust to prevent drying out of the surface and the appearance of small cracks. Chips are moistened daily with a watering can.

Concrete hardens on the second day after pouring, and gains 100% strength after 28 days. The formwork is removed after a day, and the structure can be loaded only after 2 weeks.