When installing measuring instruments in three-phase power supply circuits, special attention is paid to bringing the controlled values to a form convenient for connecting to an electric meter. With significant current loads reaching 1000 Amps, special converting devices - current transformers (CT) are used for this. If available, the maintenance and repair of metering devices connected to the line is significantly more complicated.

Appointment and features of the KIC

The PUE specifically stipulates the requirement for connecting the meter to existing power networks in terms of its switching through a device called a test box (ICC). When using it, it is possible to short-circuit the secondary circuit of the measuring transformer, which makes it possible to de-energize the supply lines for each phase supplied to the meter.

Connecting a current transformer through the test box allows you to turn the procedure for replacing and checking the meter into a completely safe task. In addition, disconnecting the load from the supply line in this case is not necessary.

Test boxes for the electricity meter are especially in demand in the following situations:

- for bypass control circuits;

- if there is a need for their complete shutdown;

- if necessary, block voltage on each of the phases;

- for connecting to the monitored line of the measuring device (electric meter).

The need for ICC boxes is also explained by the fact that there is a special group of consumers, each of which is not allowed to be disconnected from the mains even for a short time. Taking into account the fact that periodically there is a need to carry out work with the meter, the terminal test box IKK significantly simplifies all operations. In this case, there is no need to de-energize the power line and install a replacement shunt in place of the measuring device.

Fixture design

Typical adapter boxes are available in several designs, differing in their appearance and shape. Most often they have the appearance of a rectangular block with thick walls made of durable and non-combustible material (carbolite or plastic). In this design, the box resembles a substrate with groups of terminals placed on it, forming the so-called “clamp stand”.

Through its edges, through holes are made, used to fasten the KIC to the walls of the switchboard. Its connecting contacts are made on the basis of brass or galvanized steel (sometimes phosphor bronze is used for this). Some models of boxes are equipped with such additional elements as a flange or lever, simplifying the installation process.

Transition contacts are made in the form of spring-loaded plates or screw clamps placed on the conductive plates of brass, sheet metal or steel. Their use is explained by the resistance of these materials to corrosion and high conductivity. On top of the block is closed with a transparent cover made of plastic, securely fixed to the base. When operating the test fixture together with the electric meter, its cover is also sealed. For this, through ears are provided for hanging the seal or a small hole for the control screw (screw). The transparency of the protective coating allows you to visually control the exclusion of contact groups.

Typical differences

All test terminal boxes are primarily distinguished by the type of mains supply.In accordance with this indicator, they are divided into the following types:

- pads installed in 380 volt power circuits;

- the same products, but designed for 220 volts;

- low-voltage samples designed for installation in a 110 volt network.

It is customary to distinguish products in shape and working size. According to these characteristics, they can be round, rectangular or square, small in size or enlarged series.

In general, test boxes are classified by the following characteristic features:

- appointment;

- mounting method;

- the number of rows on the substrate;

- the number of contact groups in each of them;

- type of fixation and brand of wire;

- execution (corner boxes or straight lines).

For the intended purpose, the products are used together by meters or are intended for ordinary switching operations. They can be mounted on a DIN rail or installed in a cross-module. The possible number of rows and contact groups in these devices is one or two with the number of contacts from 3 or more.

In accordance with the method of fixation used, all boxes are for screw, barrier and fixed (push) fastening. The brand of the connected wire is selected depending on the type of terminal used in the box. Screw and end mounts are suitable for all types of conductors, and single-core analogs are usually inserted into spring and knife clamps. However, the main difference between the test blocks for meters in the connection diagram, according to which they are used for one metering device or for several samples at once.

IKK test boxes are produced by most major manufacturers of electrical equipment using various materials in their manufacture. This fact is confirmed by the presence of a number of products with various quality certificates.

Device mounting

Devices are in demand when laying new electric lines and, if necessary, their modernization. During installation, the requirements of the PUE relating to the rules for the operation of test boxes are necessarily met. According to the regulations, for the placement of the KIC, it will be necessary to prepare a specially equipped place, protected from the penetration of unauthorized persons and accessible to maintenance personnel.

At the terminals of the box, only wires of homogeneous metals having electrochemical compatibility may be combined.

The tightening torque of the contact screw connections must not exceed 2.5 Nm, which guarantees the safety of the terminals. In addition, they must not be damaged or show obvious defects. The fixing of the IKK case at the installation site is carried out only mechanically - by screwing it on or fastening it with the help of special latches. The box is usually mounted in an electrical cabinet immediately after the meter.

Connection Example

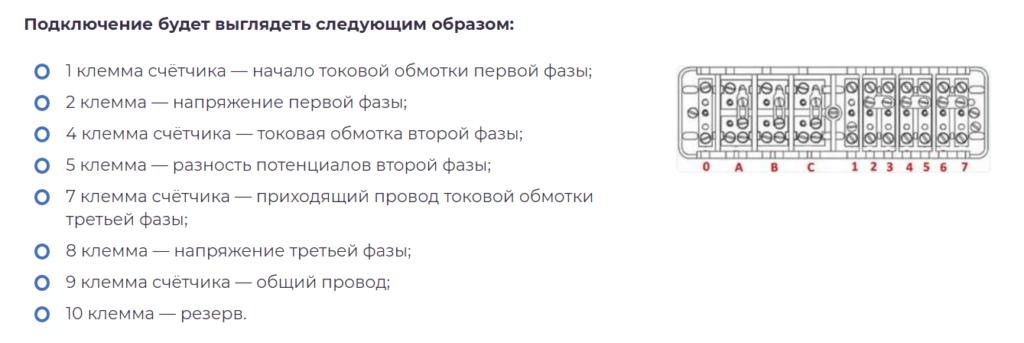

The exclusion of a real meter (CE6803 V100 / 10 T1, for example) by means of a test box is carried out according to a pre-prepared scheme.

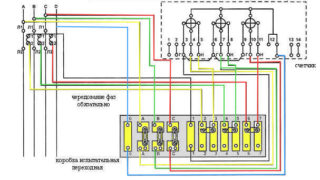

According to the PUE, all three-phase meters must be connected through current converters and a junction box combined with them.

When choosing transformers, it is more convenient to use the TOP-0.66 product with a current transfer coefficient of 200/5. As an example of connection, consider the box KI 10 or B3179, manufactured by METZ. Weight does not exceed 0.6 kg, dimensions - 68x220x33 mm. Disclosure sequence of these products:

- A counter is mounted in the working panel, and then the test box itself and current transformers.

- TTs for each phase are combined according to the “star” scheme; wherein the common terminal is grounded reliably.

- From it, wires with a cross section of 1.5 mm² are stretched to the box body.

- Three cores (2.5 mm²) are also laid from the meter.

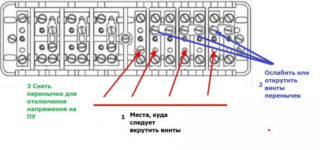

For ease of installation, all wires must be marked before laying: the beginning of all current phase windings, as well as the general conclusion, are indicated on them.In this case, the conductors from the electric meter are brought into the box from its upper part, and then are alternately disconnected in the contact group. It should have a larger plate area than the same contacts intended for taps from current transformers (they are located on the underside of the box).

For ease of installation, all wires must be marked before laying: the beginning of all current phase windings, as well as the general conclusion, are indicated on them.In this case, the conductors from the electric meter are brought into the box from its upper part, and then are alternately disconnected in the contact group. It should have a larger plate area than the same contacts intended for taps from current transformers (they are located on the underside of the box).

The excluded test plate is closed by a lid on top, after which the product is ready for use.

If you need to carry out any operations with the electric meter to remove it, you only need to remove the jumpers in the KIC. After that, the chain of its connection with the meter is broken.

The nuances of using

Test boxes as the simplest type of construction do not require special maintenance, which does not mean their absolute reliability. According to the requirements of current standards, it is recommended to tighten the screw terminal contacts regularly during the operation of the KIC. During operation, the conductors heat up and slightly deform, which causes loosening of the connections.

For boxes with clamp-type contacts, such requirements are usually not presented. In addition, it is much more convenient to handle them, because you do not need an additional tool to turn off the meter.

Procedures associated with the installation, dismantling, as well as opening and subsequent sealing of the box are carried out only by qualified specialists.