During the repair, it is often necessary to face the replacement or laying of new wiring. To choose the material, you should study the characteristics of the options offered on the market and their useful life. If the budget is limited, aluminum can be preferred.

Benefits of Aluminum Wiring

The material is light weight. This fact allows wiring in large buildings without significant burden on the foundation. For the same reason, an aluminum cable is considered a priority for laying power lines. In the days of the USSR, almost all buildings were fed with this material.

The metal is corrosion resistant. In the open state, aluminum instantly reacts with oxygen. As a result, a film forms, which in turn protects the wire from further oxidation.

Another plus is the low price. If you compare the wiring with a similar copper product, the first is cheaper.

Terms of Use

The apartment has a lot of household appliances powered by electricity. Based on this, the edited PUE indicates a minimum cross-sectional index of 16 square meters. mm This parameter applies to the wiring that is used to electrify the apartment.

When mounting work with aluminum products, one more rule must be observed: for connecting wires, you need to use clamping contacts. So that the metal does not oxidize, a special lubricant is applied to it. This method of connecting individual elements will minimize the level of transition resistance.

There is another option that is relevant for installation in a junction box. The bare rods are connected together by welding. This is a laborious process that takes longer. Therefore, masters often resort to clamping contacts. However, qualitatively the result of applying the second method will be higher.

With a partial replacement of the old wiring, it is often necessary to connect copper conductors with aluminum. If you do this directly, the following happens:

- oxidation and weakening of contacts;

- heating of veins with different resistance;

- melting insulating braid and bare metal;

- short circuit and fire of materials.

Electricians connect dissimilar wires in safe ways:

- Steel bolt, washers and nuts. Galvanized parts are not recommended. The connection is cumbersome, but in practice the effectiveness of such a contact has been verified. The main thing is that the bare parts of the wires do not have the ability to touch each other.

- A clip called “Walnut”. In this case, there is no need to cut the wire. It is enough to clean a small area, which will be placed between small metal plates. When using this type of clamp it is worth paying attention to the material. As a rule, they are made of stainless steel, which can lead to overheating of the wires. Contacts are placed in a "shell" of refractory plastic.

- Terminals into which bare metal is inserted. Inside the clamp is a paste that interferes with the oxidation process. Masters recommend using them only on lighting fixtures.

- Pads. Their use will require periodic tightening of the screws - approximately every 6-8 months. When choosing this clip, you should make sure its quality.

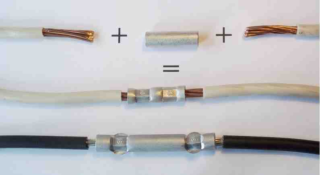

The best option for connecting dissimilar wires is considered crimping. The essence of this method is that the veins are cleaned of oxide, covered with hot tin.Next, the wires are inserted into the sleeve GML, which is pressed.

For tightness, the contacts are treated with a heat-shrink adhesive. It is important to be careful with aluminum, which by its nature is soft and brittle metal.

When choosing wires, it is worth considering the level of load that they can withstand depending on the cross section. For example, 2.5 mm corresponds to 4.4 kW, 10 mm to 11 kW, and 70 to 36.3 kW.

Life time

When installing electrical communications, each consumer wants to take into account the facts of reliability and durability. The service life of aluminum wiring can be nominal, warranty and actual.

Nominal

The theoretical indicator is taken into account at the design stage. If you follow all the rules of installation and operation, then the time period will be 25-30 years. In this case, the temperature should not go beyond -50 to +50 degrees Celsius. It is important not to forget about the need for preventive work and constant monitoring of the status of contacts.

Warranty

The indicator, as a rule, differs from the nominal term in a smaller direction. It can be as little as 5 years. In this case, for a free replacement, there are strict conditions that must be met:

- storage of products;

- transportation;

- the installer has a license;

- Operating conditions.

The last paragraph implies a load that should not exceed that specified by the manufacturer.

When choosing a transaction, the actual value should be important for the buyer. With the right choice of cross-section and automatic machines, proper maintenance, the life of aluminum wiring can reach 100 years. However, it all depends on the quality of the alloy, the laying and use of the network.

The disadvantages of aluminum wires

The limited service life of the wires is due to the characteristic behavior of aluminum in the conditions of its operation. When the temperature changes, the metal is deformed. The more times it expands and returns to its shape, the higher the risk of a break in the cable core.

The fragility of aluminum eliminates the possibility of bending the wire when laying it. It also leads to heat and fracture.

Naked contacts are almost instantly oxidized. The resulting film greatly reduces the level of current conductivity, which leads to a decrease in the cross section of the wire and lower the permissible value of the withstand load. This will be followed by overheating and destruction, which contribute to the appearance of fire.

How to extend wiring life

In order for aluminum wiring to last as long as possible, it is necessary to follow the rules for making contact connections and use protective equipment. It is also important to monitor the general condition of the wires.

Non-compliance and violation of operating requirements will lead to the rapid failure of any wiring. Periodic monitoring of contacts will prevent damage and extend the life of the communication.