The electrical industry offers customers a wide selection of conductors for creating electrical wiring, connecting devices to the mains. All products (wires, cords, cables) have their own technical characteristics, operating conditions and purpose. In order to be able to understand the variety of goods and choose the best option for work, you need to understand what kind of wires are and correctly decipher the marking.

Basic concepts

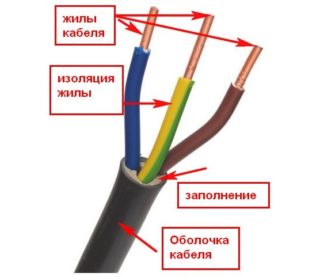

A wire is a product that consists of several parts that conducts electric current. Conductors are used to connect devices to the power point. The main parts include lead cores and an insulating layer.

Under the residential understand a wire of metal, which conducts an electric current. Its most important characteristics are the material of manufacture, the number of thin wires and the cross-sectional area. Wires can be divided into single-wire (monolithic) and multi-wire. The conductor flexibility depends on the number of cores - it increases with the number of wires. How much current a wire can conduct depends on the cross-sectional area. Each material can pass a different current with an equal cross section. To select a wire, you need to use special tables that indicate the maximum load for a certain cross-sectional area.

Insulation is a dielectric protective layer that helps to protect a person from direct contact with a current conductor. In addition, the insulation allows you to place several cores side by side without the risk of a short circuit between zero and phase, and also protects the wire from the negative effects of the environment. Typically, the insulation layer is made of PVC, rubber, polyethylene and other materials.

Often several layers of insulation are made. Additional protective layers are necessary when laying the wire in difficult conditions, unstable soils, under roads. The composition also includes armor, outer and outer protective layers.

Information on wire material and insulation, cross-sectional area can be found in the alphanumeric marking. It is regulated by the rules and is the same for wires and cables for various purposes. Letters indicate the type of conductor, material of execution, flexibility and other characteristics. The numbers show the cross section and the number of cores.

Difference in conductors by material

The main materials from which different types of wires are made are copper and aluminum. Less commonly, cores are made of steel wire. The types of cables and wires and their purpose depend on the properties, characteristics and positive qualities of a particular material.

Aluminum

The veins made of aluminum became a real discovery in electrical engineering. Aluminum is the fourth material in terms of electrical conductivity after silver, copper and gold. This made it possible to reduce the cost of cable production and make electrification easier.

The benefits include:

- cheapness;

- chemical resistance;

- low weight.

Disadvantages:

- fragility;

- destruction of the protective oxide film under the influence of temperature;

- difficulty soldering;

- deterioration in electrical conductivity due to the presence of impurities;

- short service life.

Aluminum requires regular maintenance, so such wiring will eventually cost more than copper. In addition, the short service life and fragility make long-term use of aluminum disadvantageous. For this reason and for safety reasons, aluminum wires must not be used in laying new power lines.

Copper

Copper conductors are highly conductive. Other benefits:

- high flexibility;

- elasticity;

- Reliability;

- durability;

- ease of soldering and welding;

- long service life.

Disadvantages:

- cost;

- high weight due to high density;

- contact oxidation in air - it is necessary to lubricate the damaged area with special means.

Copper is more beneficial to use. This is due to its characteristics, duration of operation and ease of installation. It is copper conductors that are used in all types of electrical wiring.

The main types of wires

The most important factor when choosing an electric wire is the power of the connected household appliance. In everyday life, the types of electrical wires PUNP, PPV, PVS, ShVVP and others are most often used.

Flat wires

All cables from this group have similar characteristics and purpose.

- PUNP - a flat conductor with protection and single-wire copper conductors of the PBPP brand (may also be called PUNP) has a cross section from 1.5 sq. Mm to 6 sq. Mm. As external and internal insulation, PVC is used. Operating temperatures - from -15 ° to + 50 ° C. The minimum bending radius is 10 diameters. It operates at voltages up to 250 V and a frequency of 50 Hz. The main use is a lighting group, sockets.

- PBPPg - Already by name you can understand the distinguishing feature of this conductor - this is its flexibility. The multicore structure allows to reduce the bending radius to 6 diameters. The remaining characteristics are similar to PBPP.

- APUNP - The wire with the designation APUNP is a single-wire aluminum conductor. Section 2.5 - 6 sq. Mm. The remaining characteristics are similar to the PUNP wire. The cable is rarely used, since it is prohibited by the provisions of the PUE. It has a low cost.

All of these flat wires can only be used in lighting. For other purposes, it is better to purchase other conductors.

With jumpers

The main representatives of this group are PPV, APPV. PPV is easy to determine by the characteristic jumpers between the conductors, which are made of PVC, as well as the insulating layer. Consists of 2-3 single-wire cores with a cross section of 0.75 -6 sq. Mm. It operates at a voltage of 450 V and a frequency of up to 400 Hz. Operating temperatures from -50 ° C to + 70 ° C. The insulation is resistant to combustion, alkali and acids. It can be used at 100% humidity. The minimum bending radius is 10 sizes of diameters.

The main representatives of this group are PPV, APPV. PPV is easy to determine by the characteristic jumpers between the conductors, which are made of PVC, as well as the insulating layer. Consists of 2-3 single-wire cores with a cross section of 0.75 -6 sq. Mm. It operates at a voltage of 450 V and a frequency of up to 400 Hz. Operating temperatures from -50 ° C to + 70 ° C. The insulation is resistant to combustion, alkali and acids. It can be used at 100% humidity. The minimum bending radius is 10 sizes of diameters.

An analogue of the described conductor is an APPV with aluminum conductors. The section starts from 2.5 sq. Mm. These types of wires are suitable for lighting and power groups.

Single core

The reclosure is made of aluminum and is a single-core conductor with a cross section of 2.5 square mm. up to 16 sq. mm. single-wire and 25-95 sq. mm. for multiwire structure. PVC is used as insulation, which allows working at 100% humidity and temperatures from -50 ° C to + 70 ° C. There are no restrictions on use.

Also, representatives of single-core electrical products are PV1 and PV3. The numbers in the marking indicate the class of flexibility. As a wire, a single-wire copper core with a cross section of 0.75-16 square mm is used. or multiwire with a cross section of 16-95 sq.mm. Soft wire PV3 is actively used in places where frequent bends and transitions are required.

Conductors for electrical cords

PVA - a copper wire with a multicore structure, having a cross section of 0.75-16 square mm. The insulation is multi-colored for the convenience of the master, the shell is white. It operates at a frequency of 50 Hz and a voltage of 380 V. It has a high level of flexibility. Designed for approximately 3000 bends or more. Operating temperature range from -25 ° С to + 40 ° С. Modification of PVSU is applied from -40 ° С to + 40 ° С.

ШВВП is a copper stranded conductor for connection, consisting of two or three stranded wires. The cross section is 0.5-0.75 sq. Mm. Not used in wiring inside walls. The main application is the lighting group and low-power household appliances.

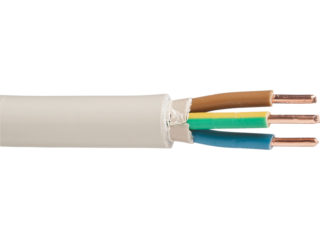

Power cables

Crimp power cables are used for indoor and outdoor wiring.The most common is domestic VVG. It is used to transmit current up to 1000 V. There are various modifications of wires with single-wire and multi-wire conductors with a cross section of up to 240 sq. External and internal insulation made of PVC. Maximum working temperature + 40 ° C, humidity 98%. The most popular modifications include AVVG (from aluminum with single-wire cores), VVGng (non-combustible), VVGz (with filling between the insulation of rubber shavings or PVC threads). The minimum bending radius for all modifications is 10 diameters.

The European counterpart of VVG is NYM. It is more reliable, as it is made of high quality materials and has passed more stringent testing. By designation, it is a household cable for sockets or lighting. The maximum voltage is 660 V. The bending radius is 4 diameters. Operating temperature range from -40 ° С to + 70 ° С. Do not use NYM when exposed to direct sunlight and lay directly in concrete.

KG flexible cable consists of 1-6 stranded copper wires. It is designed to operate on voltages up to 660 V and a frequency of not more than 400 Hz. For internal and external insulation, rubber is used, which gives the wire additional flexibility. It works at temperatures from -60 ° С to + 50 ° С. A scope - connection of powerful installations (welding machine, heater, generator). It is expensive, so in everyday life VVG cables are used more often.

VBBSHv - a copper conductor with single or multi-wire cores. It has a cross section up to 240 sq. Mm. The insulation is made of PVC material. Under the lower shell armor is created from two metal bands. It can withstand loads up to 1000 V and temperatures from -50 ° C to + 50 ° C. Typically, the following modifications are used - AVBBSHv (from aluminum), VBBSHvng (non-combustible), VBBSHvng-ls (there is no emission of smoke and caustic gas during smoldering).

Information Conductors

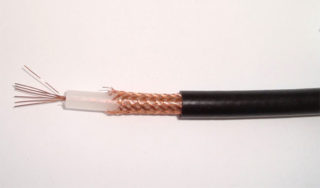

Connecting telephones, computers, television antennas is done using special cables for transmitting information.

The PK75 antenna cable consists of a copper single or multi-wire core. The cross section is 1 sq. Mm. The insulating layer is made of polyethylene and shielding braid. The outer insulation is made of cambric. It is used to transmit low-current signals of high frequency.

Computer twisted pair cable is used to connect a PC to a local network. It represents 4 or 8 wires that are intertwined with each other in pairs. For added protection, a burst thread is installed. There are different types of cables with and without shielding, which are used for various purposes.

Telephone wires are low current. They allow you to mount telephone lines in the house or lay them between substations.

Specialized Cables

For work in non-standard conditions, conductors with special characteristics are used. These include the PNSV heating wire. It is made of steel and galvanized. For insulation, heat-resistant PVC or polyethylene is selected that retains its properties in the temperature range from -50 ° C to + 80 ° C. They work at a load of 220-380 V. The main scope of application is the creation of underfloor heating.

Runway - copper cable with a cross section up to 25 sq. Mm. has double insulation made of polyethylene or PVC. It works up to 660 V. It is capable of working at sharp pressure surges and temperatures from -40 ° С to + 80 ° С. It is usually used to power pumps that are lowered into wells.

RKGM - copper single-core power heat-resistant installation cable. The cross section reaches 120 sq. Mm. It operates at voltages up to 600 V. Organosilicon rubber is used as insulation material. The outer shell is made of fiberglass. Properties are stored at temperatures from -60 ° C to + 180 ° C. The scope is places with elevated temperatures (baths, saunas, electric furnaces).