The production and transmission of electricity to consumers is not an easy task and has a large number of features. Sooner or later, every homeowner is faced with wiring replacement issues. It is important to know the advantages and disadvantages of the materials of manufacture, as well as the service life.

Rules, orders and PUE for aluminum and copper wiring

In accordance with the amendments adopted in 2019, wiring in residential premises can be made of aluminum and copper cables.

However, not aluminum wires of the 60-70s sample are suitable for operation, but modern alloys with some iron content. The main thing is to comply with the requirements given in the table.

| Line name | The smallest section of cables and wires, mm.kv | |

| With aluminum alloy conductors | With copper conductors | |

| Group Network Lines | 2,5 | 1,5 |

| Distribution network lines for residential premises (risers) | 6 | 4 |

| Lines from floor to billboards and to the meter | 4 | 2,5 |

Ban aluminum wiring in the apartment

In accordance with international standards, old-style aluminum wiring is recognized as potentially fire hazardous, therefore it is prohibited to carry it out. A few facts that confirm this:

- In the world, cases of fire were repeatedly recorded, the cause of which was aluminum wiring. As a result, more than a dozen people were killed.

- According to statistics, in apartment buildings and country houses with an aluminum electric grid, the spontaneous combustion rate is 55 times higher than the number of fires in rooms with electric wires made of other materials.

- According to chapter 7.1. PUE. Clause 7.1.34 this type of wiring is allowed for use only in structures that were built before 2001.

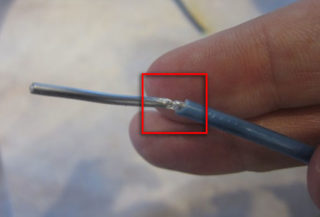

- To prevent a fire? Do not connect copper and aluminum wiring, for example, by twisting.

The aluminum wiring of the old model was not unjustifiably banned for use. There are more reliable and affordable materials that will not allow spontaneous combustion under increased load.

Properties of aluminum wiring

Aluminum is not the best option for indoor wiring, but the material has several advantages compared to peers. We are talking about low weight, which greatly simplifies installation work, provided that a large amount of aluminum cable is required. The cost is lower compared to copper. These two main advantages became decisive when choosing the types of wiring during the construction of structures in the USSR.

Another important feature of the material is corrosion resistance. However, aluminum is strongly oxidized by interaction with air. The result is a film that protects against further damage to the wiring. This film has poor conductivity, which can be attributed to another drawback.

In comparison with aluminum wiring, it is better to give preference to copper for the following reasons:

- During oxidation, copper does not lose its conductive properties.

- It has a long service life.

- The material is more resistant to mechanical stress, such as bending, twisting, etc.

During oxidation, films are formed in both cases, but each has different conductive properties.

Aluminum fluidity

First of all, you need to know about the physical and chemical characteristics of aluminum. The substance belongs to the group of flowing metals; it is several times softer than copper. This is a significant drawback, as homeowners have a need to regularly check and, if necessary, pull all screw contact points, for example, in sockets, circuit breakers and terminal blocks. This is very inconvenient if there are 10 or more sockets in the house that need to be disassembled, tightened and mounted once a half-year.

Flexibility and fragility

The second feature of aluminum conductors is brittleness and fragility. If you bend them several times, they break off without much effort. To deform copper, you need to make a lot of effort.

When installing aluminum wiring, one must be very careful and accurate in their actions, since shifting, twisting and twisting the contacts will lead to breaks.

Connection of aluminum to automatic machines

The third feature of the material is the contacts of the switching equipment. For RCDs, circuit breakers, voltage relays, contactors, terminal blocks and starters, they are initially made of copper or brass.

If brass-aluminum = copper-aluminum contacts are directly connected, a galvanic pair is formed, accompanied by strong heating of the junction and the formation of oxides.

Cross section

Another feature of aluminum wiring is the need to increase the cross-section of the wiring conductors. If earlier it was enough to use cables with copper conductors of size 2.5 mm.kv, now there is a need to lay at least 4 mm.kv.

Is it possible to change old aluminum wires in an apartment

Steel-aluminum wire must be changed. One of the most significant reasons is the maximum load that it can withstand. Even a fully functional and productive wiring installed several decades ago will not be able to withstand the stresses of today. This is due to the large number of household appliances installed at home. And it is strictly forbidden to additionally equip the wiring with a large cross section, as this can cause overheating and due to fire.

It is recommended to give preference to copper cables, because they are more fire resistant and reliable, withstand heavy loads.

Despite the requirements of the PUE for the operation of copper wiring in multi-apartment and private houses, on October 16, 2017, the Ministry of Energy issued Order No. 968 on permission to reuse aluminum wires. However, we are not talking about the material that was used in the 60s of the last century, but about more advanced cables, which consist of veins of an alloy of aluminum with iron.

Specialists of the Russian company RUSAL developed alloys, which were assigned numbers 8030 and 8176. On March 20, 2019, amendments were made to the rulebook that allow them to be legally used in their households.

Requirements for Removing Old Wiring

First of all, you must de-energize the packet switch. This eliminates the possibility of electric shock. The next stage is the dismantling of old wiring and equipment.

It is best to start dismantling with junction boxes. The covers, according to the layout, are located on the walls under the ceiling. From the very beginning, the lead-in wire is found, carefully insulated and cut. After that, you can proceed to extract the remaining wires.

If the cable ducts are in improper condition, it is not possible to run new wiring through them. In such cases, electricians are advised to leave the old communications intact, and to lay new ones on the surface of the walls.

Basic requirements for operation

The use of aluminum wiring is allowed subject to the basic requirements:

- The cross-sectional size should be at least 16 square meters. mm

- To connect several parts, clamping contacts are required. In addition, a special store lubricant is used to prevent oxidation of the contacts and maintain a minimum transition resistance.

- In junction boxes, special welding is used to connect parts of the electrical wires. The disadvantage is that this method is rarely used because of its high cost and time.

If masters were called for soldering, you need to personally monitor the quality of the work performed so that everything is carried out in accordance with the technical requirements.

The maximum allowable load on aluminum wiring of different cross-sectional sizes.

| Conductor cross section, mm | Aluminum conductors and wires | |||

| Voltage 380 V | Voltage 220 V | |||

| Current, A | power, kWt | Current, A | power, kWt | |

| 2,5 | 19 | 12,5 | 22 | 4,4 |

| 4 | 23 | 15,1 | 28 | 6,1 |

| 6 | 30 | 19,8 | 36 | 7,9 |

| 10 | 39 | 25,7 | 50 | 11 |

| 16 | 55 | 36,3 | 60 | 13,2 |

| 25 | 70 | 46,2 | 85 | 18,7 |

| 35 | 85 | 56,1 | 100 | 22 |

| 50 | 110 | 72,6 | 135 | 29,7 |

| 70 | 140 | 92,4 | 165 | 36,3 |

| 95 | 170 | 112,2 | 200 | 44 |

| 120 | 200 | 132 | 230 | 50,6 |

The service life of aluminum wires, subject to all operating rules, reaches several decades, but if you neglect the technical recommendations, problems will begin in six months or a year.

https: //