Safety of working with electrical equipment is ensured by grounding. In the event of a leak, it draws current into the ground, so that when a person touches metal parts, he will not be damaged. One way to create protection is the main ground bus. It is designed to connect several conductors for grounding and equalization of potentials. The tire may have a different design, dimensions and installation methods. When working with it, a number of nuances must be taken into account so that the installation and subsequent operation take place efficiently and reliably.

Ground bus design

GZSh (main grounding bus) is a protective element that is mandatory when creating any electrical networks. Grounding allows you to protect a person and a home in the event of an emergency or current leakage.

The entire system of the main grounding bus is made of metal (steel, copper). In the role of structural elements, water pipes, a gas pipeline, steel structural elements and other metal parts can be used. Often, ventilation and air conditioners are used to create a grounding system.

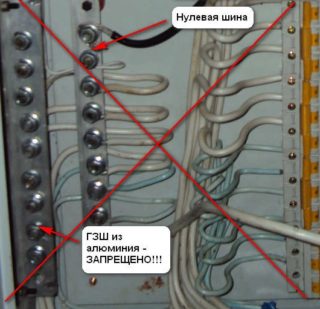

PUE requirements allow the use of not only steel, but also copper grounding devices. Steel is used more often because of its cost, but copper is better for technical specifications. It practically does not oxidize, has good electrical conductivity, is reliable and does not rust. Aluminum is not used, as it is prone to oxidation and has insufficient resistance.

GZSh has a smaller cross-sectional area than the protective wire or zero. The section is selected depending on the metal. For copper wires in installations up to 1000 V, an area of 10 sq. Mm is required, for aluminum from 16 sq. Mm., For steel from 75 sq. Mm.

According to GOST requirements, at least five simultaneous connections must be connected to the main grounding bus. Typically, copper busbars are capable of simultaneously connecting 14 or 18 rails. This number of connectors is enough for 10 or more apartments with the condition of uniform load distribution.

There are two main types of grounding buses - REC-ET2-M and REC-ET. The first type is usually installed in special profiles in cabinets. The tire holder requires a special organizer that protects the device from corrosion, which allows you to connect up to 9 consumers.

Size requirements

Current regulations indicate what dimensions a tire should have. It should be in the form of a strip on which the required number of contact holes for bolted joints can fit.

For industrial products of the brand XX-UHL4 TVS, the following standards: 3 × 30, 3 × 40, 4 × 40 mm. The number of holes is also standardized - 10, 15 or 20. These sizes may vary depending on the manufacturer, but all proportions must be maintained. All characteristics of the main ground bus must also be maintained.

Security element

The main ground bus is protective equipment. It is used as the main element of the protective circuit to divert lines through residential buildings and industrial buildings. Similar products are used when connecting equipment with a voltage of up to 1000 V.

The device is a connecting element for several different power consumers. It provides the operation of the entire grounding system in the building. Also, it must equalize the potentials in the electrical network. Thanks to the bus, you can separate the conductors and connect the contacts.

In addition to the main grounding bus, the system includes a set of copper connectors and a design of a metal profile or reinforcement, which is a grounding contour. This circuit must be driven into the ground near the building to ensure reliable contact of metal and soil.

Usually, the grounding bus collects conductors from the following structures:

- main ground loop;

- cases of pipelines, metal equipment;

- lightning conductor.

Also connected to it is a PEN conductor, which is part of the cable supply voltage.

It is important to consider the grounding system at the design stage of the house.

Installation location

The main bus can be placed inside the input device of electrical installations. In case of separate installation, the tire should be located in a convenient accessible place.

If the product will be placed in places accessible only to qualified workers, you should choose an open location. If there is a risk of access by unauthorized persons, you should put the grounding bus in a protective shell - a cabinet, a box, a box with a key. There must be a grounding mark on the shell body, as well as a table with the technical characteristics of the product.

If the building has several separate inputs, a bus is installed on each input equipment. All buses should be connected by a conductor, which will equalize the potentials. The cross section of the wire must be at least half the cross section of the PE cable. All parts must comply with the requirements of GOST and PUE.

The main way to connect the wires is welding. It is characterized by high reliability and durability, so that the contact will meet all the necessary safety requirements. Terminals and clamps are also used. They are easy to install and inexpensive, but have less reliability than welding and soldering.

Protection Box Installation Requirements

The installation of the box has special requirements. The shield must be equipped with a lock so that there is no unauthorized access. It can be placed at a height of at least 150 cm from the floor so that children do not accidentally climb into the drawer. The installation location should be selected taking into account that the environment also affects the operation of the ground electrode. For this reason, in the case of 80% humidity, the air temperature should be about 15-20 ° C. At higher or lower temperatures, the reliability of the structure will deteriorate. It is not recommended to put the box in places with aggressive chemicals, as well as sources of fire and heat.

When installing structural elements that implement working grounding, the following points should be considered:

- To make the installation convenient and reliable, you should fasten the main grounding bus with bolts on the steel casing of the box.

- During installation, it is necessary to connect the ground bus and the zero rail using a steel or copper jumper.

- The dimensions of the tire should be comparable with the cross section of the zero working and protective wires.

- Installation of wires relative to each other is not regulated by the norms and requirements of official organizations.

The requirements for the cross-section of the PE grounding plates also apply. The cross-sectional area must be at least 10 square mm, if copper is selected as the material. If the plate is made of steel, the minimum section is 75 sq. Mm.

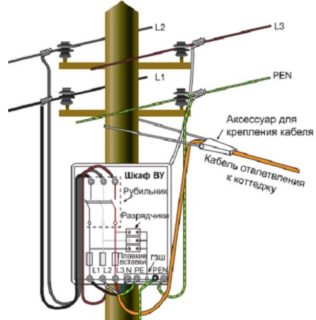

On an air line pillar

The installation of the main grounding bus can be carried out on an additional input device, if any. It can be a pole on which the supply line is supplied. According to the requirements of the PUE and other applicable standards, it is necessary to connect the bus installed on the pole with the main distribution strip, which is located in the internal input device.

In addition, it is necessary to re-arrange the grounding of the PEN wire on the pole by allocating a separate grounding bus for it.

Outside installation

The main bus can be mounted in places where only professional workers have access. Most often these are factories and production facilities. In this case, it is not necessary to put it in the closet. The busbar can be fixed on the surface of the insulator made of durable material. An example of such a product is a 19 inch TLK plate. The grounding bus on insulators is reliable and quality. It allows you to ground all important plant installations.

Integrated tires

The design is created completely from scratch by the master. However, there is already a ready-made device with grounding buses on sale. An example is a DIN rail, which comes with a 220 V switch to power the device. Also included are zero tires with an insulator. The maximum allowed simultaneous number of connections is 22.

On sale you can find three varieties of such rails. For circuit breakers, DIN U3 is used, also this model is available with a zero ground bus. The third type is DIN U4 with additional functionality. All products are anticorrosive and easy to install.

One of the most popular rails is the TLK-ERH-CU 19-inch. Made of copper, it is inexpensive and has a high level of quality.