Using indoor LED strip is important that its operation is stable, durable and does not have a negative impact on people's eyesight. The correct operation of such lighting devices is guaranteed by the power supply for the LED strip, which is selected in accordance with certain calculations. A correctly selected converter will protect the LEDs from power surges and premature loss of luminous flux quality.

The principle of operation of a switching power supply

Switching power supply is by far the most commonly used for LED strips. The principle of its operation is to transform the duration of the working part of the period for a rectangular pulse current, as well as the duration of its supply to the device. Such parameters are set in accordance with the zero level. This refers to the part of the period when the maximum permissible voltage can be observed. This characteristic is called latitude. Its transformations are carried out in the range of 0-100% and cause specific modifications in the indicator of the available voltage of the light source.

In such cases, the output current preserves its own stability at the most optimal level. The changes do not concern the spectral composition of the light flux, and the power dissipation is kept within the nominal values.

The power supply itself, when operating in a pulsed mode, suffers minimal losses. Regulators of this class are most optimal in order to implement a computer or digital method of controlling the degree of illumination.

The main disadvantage of such models is the increased level of flicker. But it is peculiar to extremely cheap power supplies. A similar effect is harmful to human eyes and can occur even at low brightness levels. Long tracking of such a light phenomenon can cause:

- the formation of unpleasant visual sensations;

- headache development;

- fatigue growth;

- decline in mindfulness and visual acuity.

To avoid negative effects, it is better to give preference to branded power supplies. They are somewhat more expensive, but lack this effect.

Key selection criteria

To choose the power supply for an LED strip, you need to pay attention to such key characteristics of this device:

- value of the output voltage - it must necessarily correspond to the indicator of the lighting device;

- device power indicator - calculated by a special formula;

- level of protection;

- the presence of additional features.

When choosing a power source, you also need to consider its cost. Moisture protected models will cost more. Pricing is influenced by the device conversion method and its performance indicators.

Conversion method

By the method of conversion, power supplies can be divided into 3 main types:

- linear

- transformerless;

- impulse.

Linear power supplies were invented back in the last century. They were actively used until the early 2000s, before the appearance of pulse devices on the market. Now practically not applied.

Transformerless models are unsuitable for powering LED lamps. They have a complex structure - the voltage of 220V in them is reduced by means of an RC circuit with subsequent stabilization.

The most popular is the pulse-type converter.It is favorably distinguished by the increased value of efficiency, small weight and compact dimensions.

The main serious minus - the unit cannot be turned on without load. Otherwise, the power transistor may fail. On modern models, this problem was solved using feedback. As a result, at idle, the voltage at the output does not exceed the allowable indicator.

Cooling

Depending on the cooling system used, the power supplies are divided into 2 types:

- Active cooling - the device is equipped with an internal fan, which is responsible for the cooling efficiency. This design makes it possible to interact with high enough power. At the same time, the fan may be humming and must be cleaned periodically, since dust enters the housing with air flow.

- Passive type cooling - the device is not equipped with a fan (free cooling). Such power sources are very compact, but at the same time suitable exclusively for domestic use, as they are designed for small loads.

Execution

By type of execution, power supplies are divided into such designs:

- Small plastic case. Such a device looks similar to laptop power supplies and has a collapsible plastic case. Models of this class function stably and will be the best option for use in dry rooms.

- Sealed aluminum housing. Design features, tightness and strength of the material used, allow the use of such an LED block in rooms with high humidity. It is resistant to moisture and has a long service life.

- Metal housing with ventilation holes. Such devices are not protected from external influences, therefore they are mounted in special closed boxes. The open housing allows you to quickly reconfigure the unit.

When choosing a power supply, you need to pay attention not only to its design features, but also to functionality. Do not overpay, because some of the additional functions the owner may simply not need.

Output voltage

This characteristic sets to what voltage rating the power source converts to the initial mains voltage of 220V. Usually it is 12V and 24V constant or variable type. The most common are 12V LED strips with a constant voltage type. Accordingly, they need a DC12V marking power supply.

Power

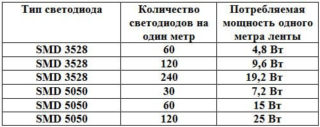

In some situations, there is simply no need for calculating the power of the power source. For example, if you need to connect 1 meter of tape on SMD class LEDs with 12V power, any unit with a constant voltage at the 12V output will do. If a more powerful load is expected, you will need to use the calculation formula.

You can choose the power of the power source based on the maximum length of the LED strip and on the consumption rate of 1 meter of the product. To facilitate this task, manufacturers prescribe the requirements for the power source in the instructions for the LED strip.

Additional functions

In addition to the main characteristics, when choosing power supplies, attention should be paid to the presence of additional functions in them:

- can be trivial and exclusively provide nutrition;

- more functional models have a built-in dimmer;

- individual devices are equipped with an infrared sensor or radio channel for control using the remote control.

The most expensive power sources are equipped immediately with a dimmer and remote control, which allows you not to clutter up the space of the room with separate units.

How to calculate the power of the power supply for LED strip

To determine the required power of the power supply needed in a particular situation, you can resort to using a simple calculation scheme.

For example, we will consider the popular tape model SMD5050 with a length indicator of 3 meters, a power of 14.4 V and a LED density of 60 pcs. per meter length.

First you need to calculate the energy consumption of the tape: 14.4V x 3m = 43V.

To account for the loss of power on the conductors, it is required to add 20% to the calculated power for the reserve: 43V x 1.2 = 52V.

The figure found that the lowest power source for this tape should be 52V. Blocks with such indicators are not available, so the figure needs to be rounded upwards - a 60V device is suitable.

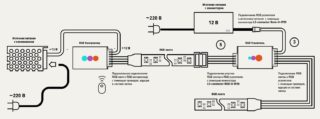

LED strip connection

Before installing in a regular place, the tape must be connected to the power supply. This process is simple and can be performed independently. For example, a block with a metal casing with ventilation holes will be considered. Such devices are most in demand. Inside the case there is a rectifier with a terminal module, which actually connects the light source.

Connection polarity

All power supplies are marked with the main purpose and its key characteristics. There is a symbol next to all terminal screws to ensure that the wires are connected correctly:

- L - phase, N - zero: this is the input of the power source. Using these terminals, the unit is connected to a common network.

- G - for ground connection. If there is no grounding in the apartment, this terminal is not activated.

- + V and -V are output terminals with converted to 12V voltage.

Power supplies of this class are equipped with an operation indicator - a green lamp. There is also a special swivel mechanism, which is designated as “V adj”. It allows you to slightly adjust the voltage - within 12-13V.

Wire cross section selection

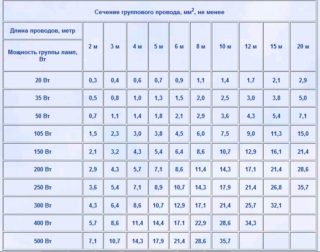

The choice of the cross section of the wire is extremely important, because the possibility of power loss when heating the lighting device depends on it. If when connecting the distance between the power source and the LED strip turned out to be large, it is necessary not only to eliminate the voltage drop on the connection cable, but also to level the power losses created by this cable.

The larger the cable section, the less power loss is observed.

To connect LED strips to the power supply, you need a cable with a cross section of at least 1.5 mm2. If the total cable length is more than 10 meters, it is better to take wires of a larger cross section, for example, 2.5 mm2.

Switching circuit selection

Before connecting the LED strip to the power source, you need to bring the cable to the installation site. For such lighting devices wires of marking VVG-P 2x1.5 or VVG 2x2.5 are used. A socket plug is installed on one end of the cable, and the second is stripped from the insulating layer to connect to the terminals of the network adapter.

The cleaned wires are inserted into the sockets of the power supply, and then fixed with screws. The connection is made to the connectors marked L and N. A brown wire is connected to the phase (connector L). A blue wire is connected to zero (connector N).

The main thing when connecting an LED strip is not to reverse the polarity, since these light sources operate from a constant current type.

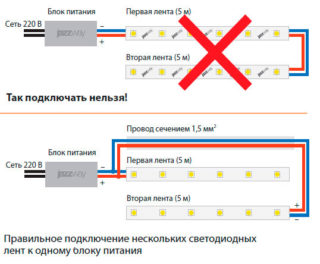

When connecting several power strips on LEDs to the power supply unit, certain rules must be observed.

Each tape should not be longer than 5 meters, it does not matter if it is solid or consists of several small segments. If the length is longer, current-conducting tracks may burn out.

Such a scheme assumes that all lighting tapes are connected in parallel, and not in series.When connecting them, it is also extremely important to observe the correct polarity.

Differences between the power supply and the driver

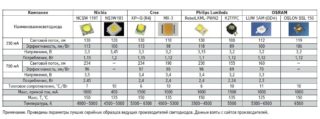

Power supplies are voltage sources that convert standard 220V to 12V or 24V. These devices are used mainly to power tapes on LEDs and those modules where a resistor plays the role of a limiter.

Power supplies are voltage sources that convert standard 220V to 12V or 24V. These devices are used mainly to power tapes on LEDs and those modules where a resistor plays the role of a limiter.

Drivers are current sources for LED devices. They are not marked with “output voltage”. Exceptionally current output and maximum power. They are used for stand-alone LEDs and modules that do not have a current limiter.