A pump that pumps well or well water correctly performs its functions only if there is a working medium. If there is no water to reduce friction and cooling, due to idle operation, the parts of the device will quickly wear out. The presence of liquids is monitored using dry run protection devices.

Dry running hazard

Structurally, downhole pressure equipment provides for the use of water as a protective agent. Cool liquid does not allow the parts of the pressure device to heat up, provides the required pressure. In addition, it is impossible to organize a traditional lubrication system for rubbing elements for downhole equipment: water also reduces the friction force.

Structurally, downhole pressure equipment provides for the use of water as a protective agent. Cool liquid does not allow the parts of the pressure device to heat up, provides the required pressure. In addition, it is impossible to organize a traditional lubrication system for rubbing elements for downhole equipment: water also reduces the friction force.

If there is no working environment:

- Parts heat up, grow in size and transfer metal expansion to the nearest nodes through metal connections.

- Gradually, the elements inside the pump become deformed.

- The unit “wedges” due to the transformation of the internal parts, which causes a voltage surge.

- The windings burn out in the electric motor, which finally destroys the pump.

Drainage of submersible pumping equipment occurs at low productivity of the deep source. If the water intake is large, the well quickly becomes empty. It will take time for the tank to fill up again. The reason for the surface pump to run on a dry run is the clogging of the pipe along which the pumping takes place. If water is withdrawn from the citywide network, water may end due to a breakthrough of the main or technical work on water supply branches.

Any type of borehole pumps for long-term operation requires a special device that shuts off the pump in the absence of the required volume of fluid.

Devices for effective protection of pumping equipment

The principle of operation of all types of dry running relays for a well pump is similar. A safety device shuts off the pump if there is a risk of idling or a lack of fluid is detected inside the pressure unit. After bringing the water level to normal, the pumping equipment starts up in standard mode.

However, each type of device has its own characteristics:

| Category | Device | Structure | Operating principle | Features |

|

Water level sensors

|

Float switch | A group of contacts is located inside the camera - "float". The device wire is built into the pump circuit. | When the water level drops, the contacts open, no current flows to the pump, and the unit shuts down. When the amount of liquid increases to the necessary criteria, the contacts are closed and the pump is connected. |

Simple and inexpensive equipment, but limited in use for narrow wells due to chamber volumes.

|

| Water level sensor | Consists of two meters lowered to different depths. | The first sensor sinks to the minimum at which the pump will operate. The other falls a little lower. If they stop contacting, the power supply circuit opens. |

The device turns off the pumping equipment even before the body rises above the water surface. Universal design, but requires professional customization.

|

| Protection relay | Includes a membrane, a group of contacts, several wires. | When the pressure drops, the membrane clamps the contacts, the power supply circuit opens. |

It can work with a decrease in pressure from 0.6 to 0.1 atmosphere.

|

|

|

Flow relays

|

Petal | In the highway there is a flexible plate - a petal. | If liquid does not enter the pressure unit, the lobe deviates from its original position, the contacts diverge and shut off the power supply. |

Ideal for pressure equipment used to maintain pressure inside the pipe during active water extraction.

|

| Turbine | Equipped with an electric magnet in the rotor. | When water passes through the turbine, an electromagnetic field arises, the pulses of which are read by the sensors. If there is no signal, the pump shuts off. | ||

| Duct controllers | An electronic device with a complex circuit, connected directly or via a transformer. | Automatically monitors several parameters of the aquatic environment at once, gives a signal about the termination of fluid supply, independently connects and disconnects the pump. |

Reliable devices equipped with non-return valves, but are not cheap.

|

|

There are combined controllers. Also, protection of the submersible pump from dry running can be carried out using frequency converters. But such options are not used on the home water supply network: they are unnecessarily expensive, bulky and energy-intensive.

Criterias of choice

Before purchasing the device, carefully study the passport of the dry running sensor and make sure that by design indicators it is suitable for your well pump.

Focus on whether the device’s enclosure is protected against water ingress. Only such devices are allowed to be mounted on deep pumps.

Check that all wires and parts of future circuits are sufficient for the power used. Otherwise there is a danger of burnout of the sensor or adapter.

Connection Features

Sometimes you can do without installing the device. The use of protective elements is optional under such conditions:

Sometimes you can do without installing the device. The use of protective elements is optional under such conditions:

- the well is deep;

- professional maintenance of pressure equipment;

- the water level in the system does not change.

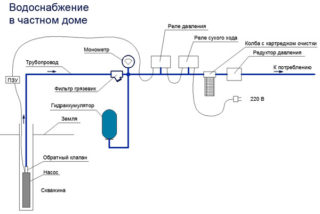

In all other cases, a device connection is required. Simple mechanical and electromechanical devices can be embedded independently. For installation, you will need the protection device itself, a suitable cable, tools for working with electric wires and keys for mounting on the pipe, as well as sealants and gaskets.

Relays are mounted before the first start of the water supply network. So you can anticipate problems and identify malfunctions. To perform a mechanical connection, you need skills in working with shaped elements. You will need to perform a threaded thread and seal the structure with linen fiber or fum tape. Cut the device into the pipe using an adjustable wrench. Then connect the electrical part. The conductors on the relay must comply with the pressure unit.

The safety device must not be connected before the water meter, otherwise it will not work correctly.

Pressure monitoring sensors are mounted with open contacts. To start the device, press and hold the red button until the pressure level reaches the desired value. If the number of atmospheres is not enough, the device will be turned off.

To connect the water flow switch, it is required to arrange them in series in the electrical network together with pressure equipment. When the pressure drops, the dry run protection will trip by opening the energy circuit.

Even an ideal protective device will be useless if you do not learn how to use it. If any sensor is triggered, do not start the pump again until you know what the problem is and fix it. Each sensor requires regular verification. In order for the system to work efficiently, you need to change elements in time that have expired.