The use of a heating cable in sewer pipelines saves the system from freezing and deformation due to ice plugs. Climatic and geological conditions do not always allow to deepen the highways so that this problem does not arise. For the high-quality functioning of the sewage system, it is necessary to choose and mount the heating element correctly.

Types of pipelines in need of heating devices

Depending on weather conditions and a variant of carrying out, the following types of pipelines are subject to heating:

Depending on weather conditions and a variant of carrying out, the following types of pipelines are subject to heating:

- cabling with laying pipes for draining sewage to a septic device or cesspool;

- sewer branches designed to drain the sewage filter;

- pipe segments that connect septic tanks to filter wells or drainage fields.

Heating can be installed on other types of pipes as insurance in case of extreme frosts unusual for climatic conditions. They use a special heating cable or lay pipe products already equipped with heating elements.

Principle of operation and advantages of a heating cable

The element is necessary for protection against freezing of pipe sections laid in the thickness of the earth. An insulated electric wire is installed on the pipe and connected to the mains.

The element is necessary for protection against freezing of pipe sections laid in the thickness of the earth. An insulated electric wire is installed on the pipe and connected to the mains.

Heating the sewer line with a heating cable has several advantages:

- the ability to maintain the required temperature level, which prevents the liquid from freezing;

- high security;

- easy and convenient use;

- energy saving due to automatic regulation system.

There is only one minus - the need to connect to the mains. On important highways, the installation of additional sources is required, which will help with a sudden shutdown of the central power supply.

Heating pipe sections in the ground is not the only area where heating wires are used. They are also used to equip a drainage system on the surface or in unheated rooms.

Types and specifications of cable

To heat the pipelines in a private house or in the country, three types of cable are used:

To heat the pipelines in a private house or in the country, three types of cable are used:

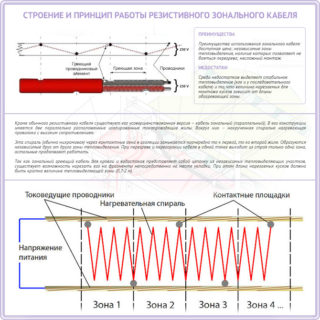

- Resistive element. Constantly heats the pipes regardless of street weather: maintains the set temperature. Electricity consumption also does not change. The heating process must be monitored all the time, but such a cable is inexpensive. When installing this type of heater, you will need to mount a set of temperature sensors and temperature controllers to change the mode of operation of the heating element when changing weather conditions.

- Zone cable. In action, it is similar to resistive, but it has a significant difference - it works in places, and not along its entire length. It is applied on separate sites and nodes of the highway.

- Self-heating option. Highly efficient and economical. Regulates the temperature regime depending on weather conditions. The principle of operation of such a heater is based on a semiconductor matrix.

The convenience of using the self-regulating option is determined by the fact that when divided into segments, it does not lose quality characteristics. It is possible to regulate the temperature regime on any segment of the heating cable. When connecting the heating wire for the first time, a one-time consumption of electricity may exceed the nominal.However, in a couple of minutes the heater equalizes power consumption.

Criterias of choice

For the effective selection of the heating system, it is necessary to evaluate the type of cable and its power per meter. The correct calculation will avoid overpayments for electricity:

- For pipe sections with a cross section from 22 to 36 mm, a wire with a power of 16 W is selected.

- If the water supply or sewage collector is assembled from pipes with a cross section of 50 to 110 mm, a 24 W heater is suitable.

- For pipe sections with a large cross section, a wire with a power of 33 watts or more is required.

Heating pipelines using a cable element will be more effective than using standard heat-insulating materials.

Mounting Methods

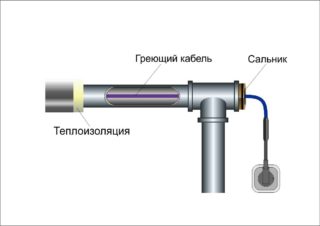

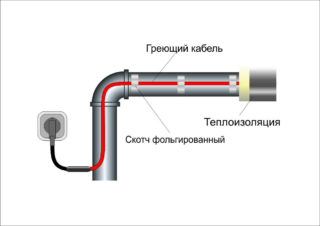

The method of location of the heating element in the pipeline can be external or internal. The cable for heating the sewer pipe is easier to mount on the outside. In this case, the electric cable envelops the pipeline or runs on top of it. If necessary, electricity is supplied to the device, and the cable begins to heat the pipe from the outside, while raising the temperature of the waste fluid. Installation of the heating element is carried out only along the pipeline, parallel to it or in the form of a wavy line, spiral.

When mounting the heating element, it is impossible to prevent overlapping wires: they can be shorted.

To lay the cable element inside the pipeline, a tee must first be equipped for easier wire entry into the system. As a result of direct contact of the electric heater with an ice plug, it disappears almost instantly. This heating option has many imperfections:

- a significant decrease in the reliability of the sewage system, since additional fittings are used;

- frequent blockages due to settling of solid impurities on foreign elements located inside the pipes;

- reducing the cross section of the sewer line, and, as a result, lowering the functionality of the entire system.

After analyzing the advantages and disadvantages of this method of installing electric heating, the owner of the house must make a choice between the effective operation of the sewer system and the qualitative removal of ice plugs. It is easier to lay a self-regulating type of heating cable inside the sewer pipe, but this is advisable only if it is impossible to perform external work.

Cable Installation Rules

The electric cable is fastened using heat-resistant adhesive tape or synthetic bandage with a pitch of 20 cm along the entire length of the sewer line. If the heating wires are equipped with a mineral insulating layer, they should be fixed with a tie strap or steel cable tie.

When choosing a suitable mount, consider the following nuances:

- The main means for securing the wire through the tape is its self-adhesive base.

- In the case of the use of bandages for electrical wires, you need to know their resistance to the influence of chemicals and high temperatures.

- When using wires in insulation made of polymeric materials, the use of metal fasteners is unacceptable.

When using adhesive tape with an aluminum base on top of the heating wires, the thermal power of the heater increases, which can adversely affect its operation.

Self-assembly of the heating wire is quite real. But if the sewage system is equipped with a large number of taps and tees, this will greatly complicate the installation process.