When installing an autonomous water supply communication, it is important to arrange a viewing well for the water supply. It is an important part of the network, provides access to the main working nodes of the highway. Here, the master can carry out repair work if necessary, sheltering from the cold or bad weather.

Purpose of wells

Thanks to such small mines, it is possible to organize:

- Free access to the equipment of the water supply system, monitoring its operability, places of branches, turns, crossing the pipeline. These places are more often subject to depressurization, leaks.

- Proper arrangement of pumping equipment in one place (hydraulic tank, automation, filter systems).

- Protection of all working elements from precipitation, debris, subzero temperatures, vandals.

- Access to shutoff valves (taps, check valves, drainage bends).

- Reception and drainage of water leaving the highway in emergency situations.

Viewing wells are equally widely used both in autonomous private water supply systems and in centralized highways. No exception - the line of industrial waste water or water supply to enterprises.

Types of wells, advantages and disadvantages

By type of building material, all viewing shafts are divided into the following types:

- Reinforced concrete (erected from the rings). They are resistant to aggressive environments, corrosion. Serve up to 20 years (for reinforced concrete). They have good frost resistance. Not affected by heaving soils. Reinforced concrete rings are characterized by a large mass, so the installation of a prefabricated reinforced concrete water well will have to be carried out using special equipment, which will entail financial costs. If at least one element is improperly installed, the entire shaft will skew over time. As a result, the well will burst.

- Brick. No less reliable option when installing a viewing shaft. It is especially good if the master’s site has leftover blocks after building the house. However, the process of installing a brick tank is time consuming, time consuming.

- Polymeric. You can buy ready-made plastic revision products, or install a simple barrel with a cut bottom. The first option is more reliable, because factory wells have stiffeners that withstand ground pressure. Plastic shafts are characterized by a long service life (up to 50 years), inertness to temperature extremes and aggressive environments. In addition, the polymer weighs a little. This allows you to work even on your own.

Any of the types of revision shafts should be equipped with a cover with a hatch. To protect the tank from atmospheric water, it is advisable to raise the entrance to the shaft 20-30 cm above the ground.

By type of destination, all wells are:

- inspection, they are also inspection or revision;

- differential ones are mounted at points of change in the height of the pipeline;

- linear set on long sections of the highway;

- engine rooms for equipment installation;

- nodal set at the connection points of several water supply lines;

- drainage.

Geometrically, all wells are round or square in design. The minimum dimensions of the mine are 80x80 cm. The depth should be at least 1 m.

How to determine the type of well

The type and type of viewing water well is selected according to the following criteria:

- The purpose of the tank. The geometry of the mine will always be the same, however, the parameters of the well vary depending on the purpose of its arrangement.Under the audit, you can do with less reliable brick or wood. For the installation of pumping equipment, it is desirable to mount a more durable tank of polymer or reinforced concrete.

- The financial possibilities of the master. Someone prefers to save at this stage of construction work, while someone invests thoroughly in each element. The device of a well from reinforced concrete rings will cost the most. Cheaper to put a plastic tank.

- The complexity of the process. Faster to mount a polymer (polypropylene or polyethylene) well. The maximum amount of time will take brickwork.

The final choice may be affected by the availability of building material on the master’s site.

Installation Steps

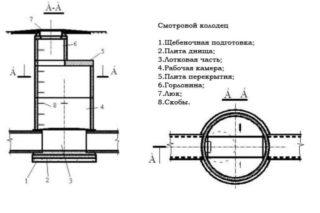

When installing a round, square or rectangular water well, it is important to initially prepare its base, especially when it comes to brickwork or installing reinforced concrete rings. Act in this way:

When installing a round, square or rectangular water well, it is important to initially prepare its base, especially when it comes to brickwork or installing reinforced concrete rings. Act in this way:

- For the installation of concrete pouring dig a pit under the mine. Its intended parameters are increased by 20-30 cm in depth and on each side.

- The soil is carefully rammed. Then a sand pillow is poured on top. It needs to be slightly moistened and compacted. A layer of sand filling is 10 cm. If we are talking about the construction of a drainage well, its bottom is made of a mixture of crushed stone and sand. A layer of buta is laid on top.

- Make concrete pouring. The solution is distributed over the entire surface of the bottom of the pit. Then it is necessary to drown the reinforcing mesh.

- Once the bottom is dry, you can put the rings of reinforced concrete or brickwork.

- Elements are lowered one after another, reliably joining them with brackets.

- All compounds are coated with sealant. You can use bitumen mastic.

- Brickwork is also desirable to process the outside and inside with a sealant mixture.

- After installation, technical holes are made in the well into which pipe outlets will be carried out. When it comes to rings, gaps are formed using a punch. For masonry, all openings are provided immediately. It is important to waterproof the pipe entry and exit points.

- At the last stage, the tank is backfilled. The soil must be compacted in layers.

The finished well is covered with a concrete cover with a hatch.

Polymer option

If you decide to put a plastic well, you can not make a monolithic base. It is enough to arrange a dense sand cushion of moist loose material.

Once the base is ready, the tank is simply lowered into the pit. It is important to make special technical holes in the caisson in advance for pipe outlets.

Backfilling of the well is done with a mixture of cement and sand. Everyone is ramming well.

The cover of the polymer well should also rise above the ground.

Features of operation and maintenance

As a rule, a manhole for water supply does not require special maintenance. However, such operational measures will be useful:

- It is worth regularly inspecting the walls of the mine for integrity violations. Cracks over time can lead to flooding of the reservoir with groundwater. Fistulas and gaps should be closed in a timely manner.

- It is necessary to monitor the tightness of all nodal connections in order to avoid flooding of the well.

- To protect the water supply system from vandals, it is advisable to provide a locking mechanism on the manhole cover.

A properly mounted inspection well lasts from 20 to 50 years without serious damage.

The location of the inspection wells on the site is regulated by SNiP 2.04.03-85.