Purification of domestic and industrial effluents, as well as storm water, ensures environmental safety. Filter units remove chemical impurities, organic matter, suspended particles. After treatment, the effluents are harmless to the reservoirs into which the discharge occurs. The most effective method of getting rid of pollution is a sorption filter for water purification.

Purpose of sorption filters

Installations for converting wastewater and surface water parameters to safe values are used when discharged into open water bodies. Sorption filters using granular filling (sorbent) capture:

- mineral sediment;

- dissolved iron;

- heavy metals;

- oil product residues;

- phosphates;

- ammonia nitrogen;

- organic pollution.

Coal-filled modules are used for high-quality liquid purification from a central water supply and a well. They remove impurities by binding them at the molecular level. An unpleasant aftertaste, color, chlorine compounds, organic matter, and fine sediment disappear. The liquid gets rid of all visible impurities, as well as nitrates and iron.

Application area

Sorption filters act independently or in combination with biological filtering devices. They are installed at various enterprises:

- petrochemicals;

- pulp and paper;

- textile;

- metallurgical;

- pharmacological and cosmetic;

- utilities.

Installations are widely used in storm sewers. Treated effluents can be used in the technical water supply system. Sorption blocks are effective at a concentration of pollution of not more than 100 mg / l.

Types, device and principle of operation

The adsorption process means the absorption by a layer of a solid of dissolved substances. The speed of the procedure depends on the structure of the sorbent, the amount of impurities and temperature. A common option for filter media is activated carbon. It is obtained from wood, coke nut shells, peat. Aluminosilicates are also used as an absorber. Sorbent is effective when it is necessary to absorb impurities of heavy metals.

Household filters for water supply are available in several versions:

- stationary;

- attachment on the crane;

- cartridge for a jug;

- desktop.

Devices vary in performance, degree of cleaning and resource cleaning backfill.

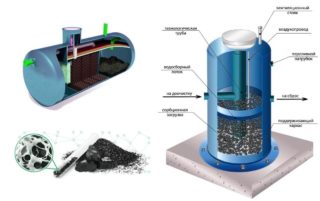

Blocks for deep wastewater treatment are a fiberglass cylinder, inside which there is a backfill. As the sorbent use:

- activated carbon (stone, wood, coconut);

- zeolite;

- aluminosilicates.

The design includes piping from the supply and outlet piping. Installations are classified according to several characteristics:

- filtration direction: direct-flow, displaced, counter-current;

- type of process: continuous or batch;

- hydrodynamic mode: mixing, displacement, mixed;

- sorbent state: mobile, motionless;

- phase interaction: continuous or stepwise.

The design of the filter is columned or capacitive.

Principle of operation:

- Cleaning in a sump, disposal of sand and oil products.

- Effluents pass through dense loading layers, usually activated carbon.

- Purified water is discharged through the pipe.

To regenerate the porous backfill, washing is carried out, its products are discharged into the sewer. The procedure takes 1-2 hours.

Advantages and disadvantages

The main advantage of sorption filters is a high degree of removal of contaminants from effluents. Among the advantages:

- simplicity of construction;

- the possibility of multiple regeneration of the sorbent;

- the possibility of using various backfill.

Disadvantages:

- Sorption blocks cannot be installed without sedimentation tanks with preliminary cleaning (sand traps).

- The equipment has significant dimensions.

- The costs of regeneration and replacement of the sorbent.

- Secondary effluent requiring treatment.

Manufacturers and models of sorption filters

Blocks for wastewater treatment are offered by Russian manufacturers, their products differ in performance and performance:

- Argel S - equipment operates in non-pressure mode. When sewage passes through the sorption charge, oil products, heavy metals, dyes, surfactants are removed. Models for underground installation are equipped with technical wells.

- NPO Industrial Water Treatment: SPP-FS 1-10 - a vertical unit with a maximum capacity of 10 l / s, SPK-FS - a horizontal model with a capacity of up to 100 l / s. Download changes 1 time in 3-7 years.

- The company "Teko-filter" produces sorption filters with coal filling FSU. They are a metal cylinder with piping and distribution devices. It is used for the treatment of storm water, the post-treatment of industrial wastewater and drinking water.

The average cost of the sorption installation of FSU is 100 thousand rubles, Argel S with loading - from 505 thousand rubles.