The essence of the reverse osmosis filter is the use of a special membrane layer, with which you can purify water from all known impurities. But for the device to work non-stop, it is necessary to maintain pressure in the line. For this, filtration columns are equipped with booster pumps.

Purpose of the pump and advantages of its installation in reverse osmosis systems

When the pressure in the pipeline is less than 2.9 atmospheres, the reverse osmosis filter device stops working normally. When approaching three atmospheres, the device begins to discharge more water into the drainage system than indicated in the technical documentation. In this situation, there is only one way out - to install pressure equipment to increase pressure.

When the pressure in the pipeline is less than 2.9 atmospheres, the reverse osmosis filter device stops working normally. When approaching three atmospheres, the device begins to discharge more water into the drainage system than indicated in the technical documentation. In this situation, there is only one way out - to install pressure equipment to increase pressure.

The models on the market are suitable for filtration devices with different types of membranes and are designed to stabilize insufficient pressure in the network. They respond to low rates - from 1 to 3.2 atmospheres.

The advantages of filters equipped with pressure installations include:

- The presence of a pump provides the system with constant inlet fluid pressure.

- The pump guarantees a stable flow, a predetermined capacity for direct-flow systems and a quick filling of the tank for devices with a storage tank.

- Filtering equipment with a pump does not depend on the number of consumers in the network.

It is recommended to install systems in houses of old construction, apartments on the upper floors, urban-type settlements, dachas, wherever pressure reliefs in the main are possible. Without a booster pump, you can confidently install reverse osmosis filters only on the lower floors or in urban private households with a central water supply.

The principle of operation and device

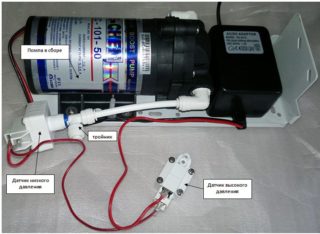

Pumping equipment is equipped with two sensors - low and high pressure. The principle of operation of a booster pump for a reverse osmosis filter is based on a change in pressure in the pipeline.

The first sensor labeled LOW on the chassis connects to the device through a tee. It turns off the pressure equipment when the pressure drops to 0.5 atmospheres at the outlet of the pre-filtering unit. This is a kind of protection against dry running. Its risk may arise from a clogged pre-treatment of the filter element or due to the interruption of water supply to the mains.

The second sensor is marked HIGH. It stops the operation of the equipment when the hydraulic tank of the filtration device is completely full and turns on the pressure equipment at a water flow rate. In addition, the device is equipped with an emergency stop pump in the absence of water.

The principle of operation of the reverse osmosis filter device with a pump is to increase the pressure of water. Pumps allow fluid to flow to the filter element and membrane, which leads to an increase in plant performance. However, they consume little electricity and work silently.

Installation Features

A water pressure increase pump is mounted for reverse osmosis filtration systems not in front of the device, but is built into it.

A water pressure increase pump is mounted for reverse osmosis filtration systems not in front of the device, but is built into it.

To install pressure equipment, you need a tee with connectors and a quarter-inch tube.

Scheme of further actions:

- Attach the tee immediately after the third flask of the filtration device.

- Feed one output to the low pressure sensor of the pumping device. To distinguish it is marked LOW, in addition, it is not end-to-end.

- Connect the second pin to the pump inlet. On the lower part of the case made of black plastic there are arrows that indicate in which direction the water flow is moving. It is important to strictly observe it.

- The outlet from the pressure equipment is connected to the diaphragm element through a four-way valve. To do this, pass the tube from the outlet to the valve and insert it into the plug hole marked IN.

- Connect the high-pressure through element with the designation HIGH at the outlet of the purified liquid from the reverse osmosis membrane. The output part is located near the center of the membrane body. To make the connection, cut the tube located there. The direction of the connection is not significant in this case.

Now you can install the filter device.

Pumping equipment is equipped with a mounting plate with anti-vibration pads, which allows connecting to almost any reverse osmosis system.

Operation and maintenance

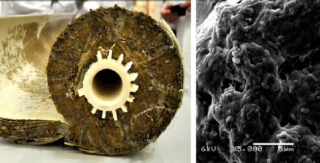

The reverse osmosis columns are arranged quite simply. The main element is a membrane that resembles a network of many steps. Each membrane cell is similar in size to a water molecule. Such a low transmittance allows you to effectively filter the liquid from hazardous substances and impurities. Only water, as well as dissolved oxygen and hydrogen, can pass through the membrane layer.

The filtering device cleans the liquid from trace elements, organic fragments, metal compounds.

To prevent tiny membrane cells from clogging, which can cause the pump to work for wear, pre-filters are mounted in front of the diaphragm. They must be cleaned regularly. Before entering the membrane, the liquid goes through several stages of filtration: from mechanical suspensions, pesticides, organic substances, chlorine.

The filter itself requires replacing the cartridges every 6 months, the membrane every 3 years, and periodically washing it inside and out. Rubber seals in the membrane body and prefilter flasks, as well as the cuffs on the membrane, are lubricated with a thin layer of silicone.

Pay attention to the condition of the storage tank. With fully drained liquid from the tap, the tank should be light, without water. Otherwise, increase the pressure in the air cavity of the tank.

Possible breakdowns

Like any technique, a reverse osmosis pump can break. If the damage is small, there is a chance to fix it yourself.

Frequent problems in such pumps and their elimination:

| Breakage | Probable cause | Replaceable Part |

| Extraneous noise at work | Bearing wear | Bearings |

| Uneven collector wear | Anchor or electric part of the motor | |

| Strong eccentric output on the motor shaft | Pump head | |

| Motor overheating | Installing an excess power pump | Pressure equipment itself |

| Worn brushes | Brushes | |

| Mud in the manifold | Anchor. Collector cleaning may help. | |

| Inter-turn closures in the armature winding | Anchor or motor assembly | |

| Power drop | Winding combustion | Engine or power supply |

If the pump does not turn on or off, it is better to entrust the tuning of the filtration equipment to professionals.

A reverse osmosis filter is the most effective. He is able to cleanse the liquid from 99 percent, make the water tasty and healthy. The performance of reverse osmosis plants directly depends on the quality of the diaphragm and the pressure of the water flow supplied to the filtration device. If the pressure in the water main is low, there is no need to talk about the normal functioning of the treatment equipment. To restore productivity, you need to install a boost pump.