Water supply to the objects is carried out by a number of mechanisms and structures: pumping stations, pipelines, filtration stations, water receivers. The coordinated work of all components increases the efficiency and reliability of systems, reduces the consumption of energy resources and improves the final water performance. To coordinate individual units, automated water supply and sanitation systems are equipped.

Requirements for automatic water installations

Modern technologies allow you to automate almost any water supply system:

- artesian women;

- filter stations;

- sewer pumping;

- first and second lift stations;

- booster stations;

- treatment facilities.

It should be borne in mind that the process of extraction, purification and delivery of water is associated with a variety of physical, chemical and biological reactions. Automation of the water supply process is carried out taking into account the following features:

- the intensity of the equipment is constantly changing;

- primary water characteristics are not stable;

- equipment is located at points separated from each other, they are controlled from a single center;

- stringent requirements for the quality of water supplied to the consumer;

- work in economy mode;

- in the event of a breakdown in one area, ensuring the operation of the rest of the equipment in the normal mode.

Complete set of automated water supply system

Automation of the water supply process is carried out using:

- measuring transducers;

- sensors for measuring indicators and, water consumption;

- blocks of data input and output;

- executive mechanisms;

- the controller.

Sensors determine the characteristics, regulate and signal problems in the processes.

Modules (blocks) of input and output translate the information received from the sensors in a convenient format for processing and delivering it further to the controller.

Measuring transducers convert controlled parameters or signals into a form convenient for storage or processing.

Controller manages technological processes using sensor data. Unlike home computers, industrial controllers are equipped with a powerful system for input and output signals from the periphery. They do not require constant monitoring and withstand adverse climatic conditions.

Actuating mechanism - receives a signal from the controller and converts it into motion. The scheme of the actuator for automation of water supply consists of a relay, hydraulic or pneumatic drive, engine.

To deliver information from the periphery to the control center are used:

- radio channels;

- switch;

- mobile telephony;

- wireless Internet;

- satellite connection.

Automation scheme for artesian sources

Automation of the process of abstraction from deep wells and the supply of water to the consumer must meet the conditions:

- the whole process is automated from receiving water to delivery to people;

- constant monitoring of water production and quantity in tanks, equipment operation is provided;

- all data is archived in the controller databases;

- Operators can change pump parameters from the control room at any time.

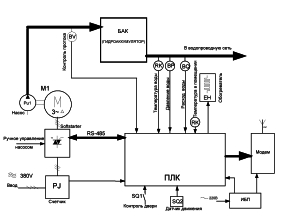

Water Automation Scheme

- In the control room, a shield with a controller is mounted, as well as a computer. The controller communicates with the computer wirelessly via Ethernet.

- Wells of an automated water supply and sanitation system are equipped with input and output units, sensors for monitoring voltage and pressure, pulse counters, and a soft start mechanism.

- Water intake stations are equipped with input and output units, current and pressure sensors, pulse counters. A motor protection unit is installed on each pump.

- A pressure meter is installed in the water tank.

- To connect all sources of water intake and stations, a twisted pair cable is used.

Each automated water supply and sanitation system is equipped with a management program. As a result, the pumps operate without human presence, maintaining the right amount of water in the tanks. They provide a given pressure in the water pipes. The circuit works efficiently when one pump is leading, others are driven. After a certain period, the lead pump changes, this prevents premature wear of the equipment. The controller of the automated water supply system counts the number of hours worked by each pump.

The controller analyzes equipment errors: open or short circuits, lack of communication with sensors, power surges, emergency limits. If the sensor breaks, information about this comes to the control panel. In automatic mode, the controller allows the pump to work by adjusting the water flow and flow.

The operator sees on the monitor information about hacking equipment, flooding or fire, air temperature, pressure and water flow, the amount of water in the tanks. The automated water supply scheme allows the operator to remotely turn pumps on or off, and restart the smooth descent mechanism.

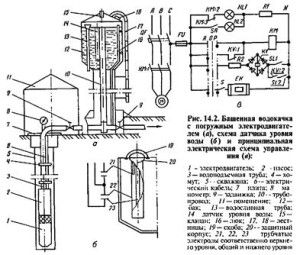

Automation of tower water intake installations

In agriculture, water supply is predominantly distributed by automated tower-type installations with submersible pumps. The tower water pump control circuit makes it possible to automatically turn the pump on or off automatically or manually, protects the electric motor from short circuits and overloads, and gives light signals about the state of the pump.

In order to switch the water supply installations from automatic to manual mode on a tower-type water pump, the SA toggle switch is set to P. When transferred to O, the installation is turned off. When there is no water in the tower, the sensor contacts open, and the magnetic starter connects. In a tower-type water supply installation, a pump starts automatically and pumps the required amount of water. As soon as water reaches the contacts of the KV relay, the current supply to the pump is turned off. When the pump is on, the red indicator is on; when it is off, it is green.

An automated water supply system allows you to reduce the number of staff, monitor all processes, sensor indicators, equipment operating modes, monitor the performance of water intake sources, and take into account the volume of produced water in real time.

Video example of water supply automation in a village in Transbaikalia: