The elimination of the causes of engineering communications accidents sometimes requires quick solutions to avoid serious threats to building structures and the irrevocable loss of material assets. The main thing is not to jeopardize the life and health of people. In some cases, it is not possible to turn off the water supply. An emergency repair of the pipeline is necessary under the operating pressure of the network.

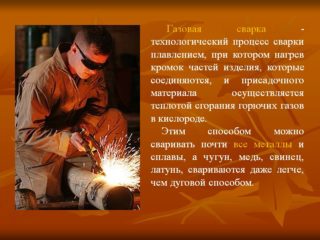

Types of welding pipes with water

The proportion of pipelines with threaded connections is negligible. In most cases, the joints of the metal elements of the route are made by welding. Sometimes unforeseen accidents occur due to installation errors, critical external load on the pipes. Leaks, cracks.

If the site requiring repair is made of plastic pipe, the accident can be eliminated either with a clamp or after the water supply is completely turned off. The temperature required for welding polymer elements will be destructive for the route in which the water is under pressure. Polypropylene becomes ductile at 95-130 ° C, and welding is performed at higher values. The electrical coupling has an operating temperature range of 250 to 300 ° C.

Metal pipes can be repaired. A qualified welder has the necessary experience to properly weld a pipe with water under working pressure. You can fix the leak in the following ways:

- Arc welding is the best reliable way to eliminate an accident.

- Gas welding - a generator and an oxygen tank are needed. It is very difficult to warm the metal in a pipe with water, so in some cases this method has to be abandoned;

- Cold welding - the principle of sealing a leak is based on the hardening of soft active substances under the influence of low temperatures, air, or after a necessary time. Cold welding is suitable for pipes with hot and cold water.

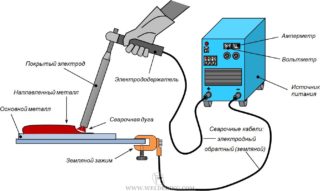

Electric welding is the most suitable option for high-quality repair of a pipe with water. Modern devices are popular with home masters. In the construction of trunk pipelines, a semiautomatic device is widely used, for independent work it is better to purchase a compact manual electric arc device. The welding inverter is affordable, anyone can perform basic household operations.

In emergency cases, you can make a homemade clamp as an emergency measure, use the kit for cold welding. After that, overhaul should be carried out in the near future.

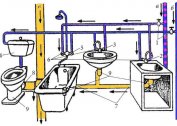

Features of welding a water pipe

For a solid reliable connection it is necessary to leave a gap of 1-2 mm, then the molten metal forms a seam with a reverse influx, the pipe edges are evenly connected to each other at a molecular level. A gap of less than 1 mm is harder to combine with this quality. The pipeline is first collected, then water is connected. Individual elements of the system are checked by special equipment for the reliability of crimping under high pressure.

For a solid reliable connection it is necessary to leave a gap of 1-2 mm, then the molten metal forms a seam with a reverse influx, the pipe edges are evenly connected to each other at a molecular level. A gap of less than 1 mm is harder to combine with this quality. The pipeline is first collected, then water is connected. Individual elements of the system are checked by special equipment for the reliability of crimping under high pressure.

Welding of main pipelines is done by electric arc devices. The method is guaranteed to withstand the required life if the process conditions are met. Pipe diameters of less than 50 mm in the wiring of houses are often made with gas equipment. In conditions of limited space and lack of qualifications of performers with the skills of an electric welder, this method is preferable.

When repairing gas welding is also used more often. However, if it is impossible to turn off the water supply, the method is not used.The temperature of the welded area does not have time to reach the desired values. Water cools the metal, a reliable connection will not work. The only option when using this method without shutting off the main supply is if there is an internal shutoff valve above the leakage point, allowing pressure relief in this section. If the design of the system allows the formation of an air congestion, there is a chance of high-quality welding of the fistula.

The fundamental difference between gas and electric arc equipment is that in the second case there is no need to heat the metal. He picks up the required temperature in a split second.

The danger is hot steam, the release of which can lead to burns. It is not recommended to weld a pipe with hot water by electric welding. In the event of a breakthrough, the consequences can be critical. Work is carried out in a mask, gloves, overalls. Excessive humidity is dangerous due to the risk of electric shock. When performing work, it is necessary to observe safety precautions when connecting to the network, placing cables.

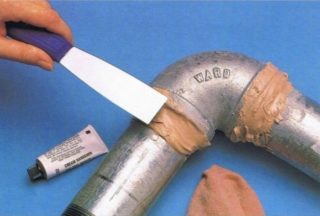

Cold welding leak repair

Repair kits for home and professional use are sold on the market and in specialized stores. The chemical composition of these drugs differ from each other, but a characteristic feature is the ability to congeal without the use of additional equipment. The plastic mass is kneaded before use, connected to the hardener, then applied to the fistula in the pipe. All work is carried out in rubber gloves. In a mild state, cold-welding substances can be harmful to the skin.

When repairing leaks in a system with water, a serious problem arises. The elasticity of the mass does not make it possible to withstand its specified time in the desired area. A stream of water breaks through the soft composition before it hardens. In this case, the option of additional strengthening in the form of a temporary bandage, clamp is possible. After preparing the necessary mass of the drug, it is clamped between the pipe and the reinforcing element for the time of hardening. You can use the factory, home-made clamp and gasket that fixes cold welding. Cold welding for pressurized household metal pipes requires utmost accuracy and precision.

The recommendations of the product manufacturers guarantee the elimination of cracks and gaps in the pipes when the water supply is turned off, therefore, when working on the site with working pressure, special accuracy, attention and accuracy are necessary. The instructions indicate the curing time. To withstand it must be rigorously. Polymerization occurs from 10 minutes to an hour.

It is not recommended to connect water depending on the type of cold welding after 8-24 hours. Using a temporary clamp can not be removed after polymerization. Must withstand the full time recommended by the manufacturer.

Features of manual arc welding of pipes with water

Satisfactory completion of the work can only be clearly understood by the task. First of all, it is necessary to inspect the damaged area. Dangers of leaks are more affected by welded pipes than seamless analogues. A fistula in the form of a crack forms at the junction. To determine the nature of the damage, it is recommended to go through this section with the skin. It becomes visible the place of the fistula, its size, shape.

Satisfactory completion of the work can only be clearly understood by the task. First of all, it is necessary to inspect the damaged area. Dangers of leaks are more affected by welded pipes than seamless analogues. A fistula in the form of a crack forms at the junction. To determine the nature of the damage, it is recommended to go through this section with the skin. It becomes visible the place of the fistula, its size, shape.

A particular difficulty arises when repairs need to be made in a hard-to-reach place. Requires skills, knowledge of special welding technologies. Experienced craftsmen use a mirror and an electrode bent at a slight angle to facilitate operation. A specialist can distinguish between molten metal and the resulting slag. An inexperienced artist may not notice the nuances, and the quality of the seam will be insufficient for prolonged use.Such repairs will last a year or two, then the pipe will leak. Entrusting work to a specialist is better.

Pipe welding is considered a complex operation. The qualifications of a master who worked only with structural building rental may not be enough. With water pressure, the operation is complicated. This event is highly recommended as a temporary measure.

GOST does not provide for pressure welding. The operation involves the emergency elimination of the accident. At the first opportunity to turn off the water supply, it is necessary to carry out major repairs, replace the damaged area.