Before entering the residential area, water travels a long way from a natural source through water pipes. The environment is not sterile, therefore, for safety reasons, it is recommended to use additional cleaning methods. One of them was mechanical filtration.

Purpose and scope

The use of a mechanical filter is necessary to remove coarse physical impurities:

The use of a mechanical filter is necessary to remove coarse physical impurities:

- clay

- sand

- rust.

Such filtering eliminates 60% of pollutants: removes coloring impurities that change the taste and give the smell. For use in drinking and domestic purposes, the percentage is insufficient, so the water is additionally purified. The principle of operation is simple: a dirty liquid flows through a filter that holds unnecessary suspensions.

In addition to water treatment, mechanical filtration helps to increase the service life of plumbing and electrical appliances. Filters are divided into industrial and domestic.

Types of filters

Mechanical stations for industrial Use is necessary for the production of large volumes of water. They are distinguished by high power and include several stages of cleaning:

- At the initial stage, large particles are retained that remain in the coarse filter.

- Oil products and particles that have passed the first stage are disposed of by settling. Fine fractions of different densities settle to the bottom.

- The remaining impurities are collected using centrifugal acceleration in the centrifuge.

- At the end of the fine filter, the remaining contaminants are retained.

At the end of the process, the water undergoes additional processing and gets into the apartments through the water supply. Often pipes do not differ in sterility, so water does not come to the consumer very clean. For household and drinking needs, it is recommended to use additional cleaning products.

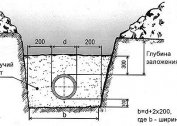

For individual application, mechanical filtration is needed in a private house when water is supplied from a well or a well in apartments with a centralized water supply. In consumer everyday life there are devices for the high-quality operation of which liquid without impurities is necessary, therefore it is worth using cleaning devices. By the method of cleaning, filters are divided into mesh and cartridge filters.

To ensure that water does not get contaminated to the consumer, systems are installed at the outlet of the water supply source netted filtering. Before treatment with biological products, it is necessary to clean from rough foreign inclusions. By type of cleaning, filters are distinguished:

- mesh non-flushing,

- mesh with automatic washing,

- cartridge.

Mesh unwashed, or mud collectors, are very simple in content. In the case there is a metal mesh that delays impurities. The size of the stuck particles directly depends on the diameter of the filtration cells. If necessary, a cleaning cycle using mud collectors, several filters are installed sequentially with cells of different sections.

Since all the dirt remains on the filters, they require regular washing, for which you need to unscrew the plugs and remove the mesh. If this is not done, the pressure will be significantly reduced.

Filters with automatic flushing simpler in everyday life. Some of them are equipped with union American nuts for simplification of installation.The design consists of a flask made of glass or metal and a glass made of food-grade stainless steel, equipped with a drain hole for flushing contaminated liquid through a hose into the drainage.

Backwashing is considered more effective when water flows in the opposite direction for cleaning. In some models, this function is embedded in the factory settings. If it is missing, you can mount the wiring option using a back pressure loop to organize the flushing.

Most models have a pressure gauge that shows the level of clogging by the difference in pressure at the outlet and inlet. Sometimes the purifier is equipped with a pressure reducer, which makes it possible to control.

Cartridge the filters do not have the ability to flush the filter element; if clogged, it must be replaced. It consists of a body, a glass and a cartridge connected to the water supply, which is a cylinder with polypropylene walls. It happens:

- spongy

- corrugated

- thread winding.

Made of non-toxic material and approved for use in food and medical fields. Cell sizes can be different, in certain situations, filters become an alternative to fine cleaning.

Criterias of choice

A high-quality filter purifies water well at a minimum cost. For individual use, it is preferable to use a filter for mechanical cleaning of water with a backwash in order to less often replace elements.

To choose the right option, you should decide on the type of cleaning in advance and find out the compatibility of the connection of the priority model with water pipes. Two purification options can be distinguished:

- Single-stage complex. It implies installation with step-by-step cleaning using a cartridge consisting of several layers with subsequent filtration. It is distinguished by the simplicity of mounting in one insert, as well as the low cost of the filter. When used in a dirty environment, it quickly loses its financial advantage due to the need for frequent cartridge changes. Therefore, the use of such filtration will be justified for the additional purification of relatively clean water.

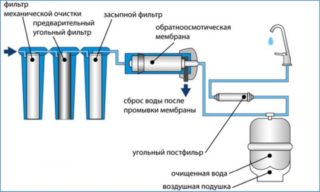

- Multistage. The fluid is passed through several elements with different characteristics that delay a wide range of particles. For high-quality cleaning of heavily contaminated water, first remove contaminants with a flanged magnetic filter, then fine debris will be collected by a mesh washing filter with a large mesh. The next step is a post-treatment, in which fine suspensions and corrosion products are removed, the cartridge filter may become the final one. Since water gets into it already well purified, there is no need for frequent replacement of filter elements.

Cleaning in several steps will help get rid of all kinds of debris and particles. The more expensive installation cost is subsequently offset by low maintenance costs.

Special elements are installed on the hot water pipes, assuming long-term operation at high temperatures up to 95 degrees. Installation of a conventional cold water filter is impractical, as the seal will quickly fail, and the cleaner will leak.

Installation Features

A suitable place for installing the filter is the area near the meter. If difficulties arise, the filter is mounted obliquely. Installation is carried out on horizontally directed pipes with the placement of the bulb below. It is necessary to take into account the direction of the water flow and place the system in accordance with the arrows indicated on the housing.

The cartridge filter is mounted taking into account the dimensions for installation and removal exclusively on the pipes horizontally. If there is no backwash device, it is necessary to mount a bypass loop and taps to switch the direction of the water flow.

Operation and use

To ensure long-term operation, it is necessary to disassemble and clean the filter unit. Particular attention is required to the sump and sump, in which it is necessary to regularly change the elements. To clean the net from dirt, it is worth washing it under a stream of water and drying it.

It is necessary to install a shut-off valve in front of the filter on the water supply pipe in order to isolate the cleaner for comfortable work in case of replacement of elements. To increase the life of the system, you should add a water pressure sensor.