Now in nature does not exist such a large industrial enterprise, which creates a large concentration:

- raw materials;

- power capacities;

- transport and oil and gas

- employees;

- other inventory items where deep air purification would not be needed.

This is an ordinary and undeniable demand of the time itself regarding the preservation of the ecology, life and health of people, increasing the efficiency of labor in the creation of goods and material goods to meet the needs of society.

The modern aspiration system in the working rooms of factories, factories, chemical, oil refineries and other enterprises is the next step on the development of ventilation to create a healthy workshop atmosphere, which, along with dust and gaseous waste products, was not so long ago removed directly into the ecological system of the region .

The aspiration process differs from ordinary room ventilation primarily in that the dry suspension of the smallest particulate matter together with polluted air is removed directly from the working area, where the most intense formation of environmentally harmful dust occurs. This approach to deep air purification technology is not only the most efficient, but also the most economical.

Equipment for suction units

For each specific workshop, the ventilation system that creates and controls the air flows in the room, and the suction units that are involved in the direct removal of the smallest particulate matter before they enter the workshop’s airspace or atmosphere, are developed jointly.

Installations for deep air aspiration are of two types:

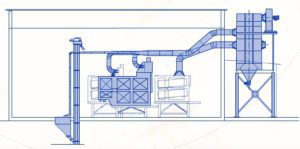

- Monoblock, when a fully autonomous installation is created with a closed process for the selection, collection and disposal of dry dust particles. Therefore, it usually consists of one or more fans, filters and a special container for the concentration of the selected waste.

- Modular when a single system is being designed with air ducts leading to different workplaces, low and high pressure fans, separators, containers for collecting and storing waste. Similar systems can be created both for a separate workshop and for a whole complex of production facilities of a plant.

There are once-through aspiration plants when the air stream after cleaning is released into the atmosphere, recirculation when the clean air stream is returned to the room either directly or through a ventilation system.

The main equipment of suction units include:

- Cyclones. This is a two-chamber ventilation device that creates a high degree of centrifugal air rarefaction: large particles are concentrated in the outer chamber, and small ones accumulate on the inner surface.

- Filtration hoses and pipelines. When passing through them, the polluted air stream loses a significant part of solid inclusions on their walls.

- Filters and sedimentation tanks. They can be placed, both instead of atmospheric cyclones, and on pipelines at transitions to ventilation.

- Catchers of large particles and metal chips. They are installed directly near the workplace, for example, next to the machines.

- Press and waste containers.

Workshop Aspiration Assessment

Assessment of the performance of aspiration in industrial production is given by:

- by the total amount of utilized waste;

- in relation to “not eliminating harmfulness” to “initial harmfulness” of the technological process. That is, in the air volume passing through the deep cleaning system, the amount of dust is determined, which avoided disposal.

Ventilation efficiency is determined only by the volume of air flow that was removed from the premises without creating drafts that could harm the health of workers.

Basically, the performance of the aspiration system is reduced by all kinds of leaks in the piping system and filter bags. They create up to 15 - 20% loss in suction efficiency and force the installation of more powerful electric motors on cyclone fans. Therefore, on operating systems, it is necessary to periodically conduct inspections and preventive repairs to eliminate defects in the joints of pipelines and filter bags.

Design and installation of suction on working technological equipment

Increasing environmental requirements is a worldwide trend in modern technological progress. Therefore, the installation of aspiration for almost all industrial enterprises is a mandatory technical measure that enhances the culture of production.

For the design and installation of air aspiration equipment, it is not necessary to modify existing processes. Since the treatment plants are made to order, the design organization adapts the suction to the existing process equipment. The binding to the conditions of a particular workshop and the accuracy in the calculations determine both the concise terms of the installation of systems and the effectiveness of its operation in the future.

At the design stage, in addition to the location of workshop equipment, foci of pollution and aspiration points, the following initial data are determined:

- Air consumption and reduced sparseness at each cleaning point.

- The speed of movement of air flows through pipelines and hoses of a certain diameter and length.

After that, calculations are made to establish the types of dust collectors, the diameters of the air ducts in each section are specified, the amount of waste and filters is determined, and so on.

After the creation of technical documentation, an installation plan is drawn up, achieving the minimum shutdown times for the process that will be required for the direct installation of aspiration equipment.