The function of any greenhouse is to protect plants from the cold. But on hot sunny days, the temperature inside the greenhouse can rise so high that the plants simply burn out from the heat. Therefore, before proceeding with the construction of the greenhouse, you should take care of the method of airing it. The most convenient, modern and effective way is the automatic ventilation of greenhouses. In addition to stabilizing the air temperature inside the greenhouse, the ventilator has another useful function: it creates a small artificial breeze, which helps to improve the process of pollination of plants.

The ventilation system for the greenhouse can be purchased, or you can do it yourself, but note that not all home-made devices can create wind, so if you wish, you can optionally equip the greenhouse with a fan.

Types of automatic ventilators

On sale you can find many ventilators working on different principles. Each of these models is distinguished by its pros and cons, therefore, when choosing a greenhouse, you should pay attention to the features of a particular model:

- hydraulic. The basis of such a device is a hydraulic cylinder with a liquid inside which a rod is installed. When the fluid heats up, its volume expands, as a result of which the stem connected to the levers is pushed out, and the levers open a window or window. The advantage of such a device can be called its durability and reliability. Some models of hydraulic ventilators are equipped with devices for adjusting the temperature at which the stem begins to extend;

- electrical ventilation systems consist of a fan and thermal relay, which is activated when the temperature rises. Such devices do not open and close the air vents, but circulate air inside the greenhouse. The disadvantage of such devices is the dependence on electrical energy;

- bimetallic system. It is a metal plate with different temperature expansion coefficients. When the air in the greenhouse heats up, one of the plates bends and opens (or closes) the window. The disadvantage of these systems is their low power;

- thermal drive. The basis of this ventilator is the property of a liquid in a container to crystallize at certain temperatures. As such a liquid, lauric alcohol is usually used. The operation of the thermal actuator is reminiscent of the operation of a hydraulic ventilator, and its advantage is also durability and trouble-free operation.

Do-it-yourself ventilator manufacturing

Since some of the devices described above have a rather simple design, it is quite possible to organize the ventilation of the greenhouse with your own hands.

To make ventilation does not take too much time, besides, a homemade device will cost much cheaper.

Multi-tank system

This device, made by yourself, consists of two containers - large and small. Most are made of metal and poured with oil. The liquid, heating up, flows into a smaller container, to which the window is attached, and the latter begins to open gradually.

- As a larger capacity, you can use a metal canister with a capacity of 3-4 liters. The smaller one can be made from an ordinary tin or glass can.

- For the manufacture of tubes through which liquid will flow from one tank to another, you can use any material. The main thing is that the tubes are long enough and reach the bottom of the tank.

- If the tubes are metal, then a welding machine is used to attach them to the canister. Rubber or plastic tubes are fastened with threaded nuts.

- A larger volume tank is filled with a working fluid, for example, used automobile oil, by approximately 35-40%.

- A small container is completely filled with liquid, while the tube that is connected to it must be filled with oil about 1 cm above its level.

- A small tank is installed on the edge of the window outside. The large one is mounted under the ceiling inside the greenhouse.

The tubes connecting the two tanks must enter them tightly! Otherwise, the system will not work.

When the outer tank heats up under the sun, oil will begin to flow into the tank located in the greenhouse. It will fall down by gravity, and the window will open, thus creating ventilation in the greenhouse.

When the temperature drops, the oil will flow back, the external tank will become heavy and its weight will cause the window to close.

Such a do-it-yourself device is quite simple to manufacture, but it has one drawback: a similar system is not able to lift massive air vents located on the roof.

Pneumatic system

To make a pneumatic ventilator for a greenhouse with your own hands, you need to prepare:

- Metal canister.

- Small cylinder with smooth walls.

- Inflatable ball.

- A piece of foam.

- Silicone sealant.

- Metal stock.

- Rubber tube.

- 2 meters of strong fishing line.

- Sewing machine bobbin.

- A small metal strip.

- Glue.

- Scotch.

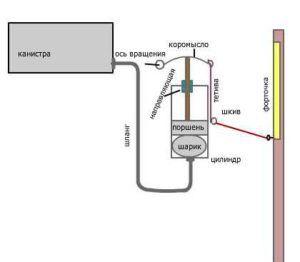

Do-it-yourself pneumatic ventilation system is somewhat more difficult to manufacture compared to the previous method, however, the use of thermal energy is also the basis of this device. First of all, you need to paint the canister black so that it better attracts solar heat. When the paint dries, a hole for the connecting hose should be drilled in the cover and the hose inserted, tightly fixing it with sealant.

For the manufacture of a smaller capacity, a piece of polycarbonate is used, rolled into a pipe, the end ends of which are glued together with cyanoacrylic adhesive. The bottom and lid of the cylinder are also made by hand from polycarbonate. In the bottom you need to drill a hole for the tube, and in the lid - a hole for the rod. For the manufacture of the guide, you can use a conventional plastic tube of the desired diameter.

Then a ball is put on the tube and hermetically fixed on it. A round piston is cut out of the foam, and its sides are pasted with tape for good gliding. Then, a rod made of metal is attached to the foam piston.

A rocker is made of a plate with two different holes at the ends. A larger diameter hole is used for mounting on an axis, and an accessory string is attached to a small one. The axis is made from a conventional nail.

Such a self-made ventilation system works quite simply. Air in the receiver, mounted under the ceiling of the greenhouse, when heated, moves into the cylinder, which helps to inflate the balloon. The piston with the rod thus rises, acting on the beam, pulling the fishing line and raising the window. When the air cools, the window closes.