Although there are many programs for calculating ventilation, many parameters are still determined in the old way, using formulas. The calculation of the ventilation load, area, power and parameters of the individual elements is carried out after drawing up the scheme and distribution of equipment.

This is a difficult task that only professionals can do. But if you need to calculate the area of some ventilation elements or the cross-section of the ducts for a small cottage, you can really manage it yourself.

Air exchange calculation

If the room does not have toxic emissions or their volume is within acceptable limits, air exchange or ventilation load is calculated by the formula:

R=n * R1,

hereR1 - the need for air of one employee, in cubic meters \ hour,n - the number of permanent employees in the room.

If the volume of the room for one employee is more than 40 cubic meters and natural ventilation works, there is no need to calculate air exchange.

For premises for domestic, sanitary and utility purposes, the calculation of ventilation by hazard is based on the approved norms of air exchange rate:

- for office buildings (extractor hood) - 1.5;

- halls (giving) - 2;

- conference rooms for up to 100 people with a capacity (for supply and exhaust) - 3;

- lounges: influx 5, extractor hood 4.

For industrial premises in which hazardous substances are constantly or periodically released into the air, ventilation is calculated according to hazard.

Hazardous air exchange (vapors and gases) is determined by the formula:

Q=K\(k2-k1),

hereTO - the amount of steam or gas that appears in the building, in mg \ h,k2 - the content of steam or gas in the outflow, usually the value is equal to the MPC,k1 - gas or steam content in the supply.

The concentration of harmful substances in the inflow is allowed up to 1 \ 3 of the MPC.

For rooms with excess heat, air exchange is calculated by the formula:

Q=Ghutsc(tyx – tn),

hereGizb - excess heat pulled out is measured in watts,with - specific heat capacity by mass, s = 1 kJ,tyx - temperature of the air removed from the room,tn - inflow temperature.

Heat load calculation

Calculation of the thermal load on ventilation is carried out according to the formula:

Qin = Vn * k * p * CR(tbn - tnro)

in the formula for calculating the thermal load on ventilationVн - the external volume of the structure in cubic meters,k - the rate of air exchange,tvn - the temperature in the building is average, in degrees Celsius,tnro - outside air temperature used in heating calculations, in degrees Celsius,R - air density, in kg \ cubic meter,Wed - heat capacity of air, in kJ \ cubic meter Celsius.

If the air temperature is lower tnro the rate of air exchange is reduced, and the rate of heat consumption is considered equal Qvconstant value.

If, when calculating the heat load of ventilation, it is impossible to reduce the rate of air exchange, the heat consumption is calculated by the heating temperature.

Heat consumption for ventilation

The specific annual heat consumption for ventilation is calculated as follows:

Q = [Qo - (Qb + Qs) * n * E] * b * (1-E),

in the formula for calculating the heat consumption for ventilationQo - total heat loss of the building during the heating season,Qb - household heat input,Qs - heat input from outside (sun),n - coefficient of thermal inertia of the walls and floors,E - reduction factor.For individual heating systems 0,15for central 0,1, b - heat loss coefficient:

- 1,11 - for tower structures;

- 1,13 - for multi-section and multi-entrance buildings;

- 1,07 - for buildings with warm attics and basements.

Calculation of the diameter of the ducts

The diameters and sections of the ventilation ducts are calculated after the general scheme of the system has been drawn up. When calculating the diameters of ventilation ducts, the following indicators are taken into account:

- Air volume (supply or exhaust), which must pass through the pipe for a given period of time, cubic meter \ h;

- Air speed If the flow velocity is underestimated in the calculation of ventilation pipes, air ducts of too large a section will be installed, which entails additional costs. Excessive speed leads to the appearance of vibrations, an increase in the aerodynamic hum and an increase in the power of equipment. The speed of movement on the tributary of 1.5 - 8 m / s, it varies depending on the site;

- The material of the ventilation pipe. When calculating the diameter, this indicator affects the resistance of the walls. For example, the highest resistance is provided by black steel with rough walls. Therefore, the estimated diameter of the ventilation duct will have to be slightly increased compared to the standards for plastic or stainless steel.

| Type of land | Flow rate, m \ s |

| Trunk pipelines | 6 to 8 |

| Side layering | 4 to 5 |

| Distribution piping | 1.5 to 2 |

| Upper air inlets | 1 to 3 |

| Hoods | 1.5 to 3 |

Table 1. Optimum air velocity in ventilation pipes.

When the capacity of future ducts is known, the cross section of the ventilation duct can be calculated:

S=R\3600v,

herev - air velocity, in m \ s,R - air consumption, cubic meters \ h.

The number 3600 is a time coefficient.

Knowing the cross-sectional area, you can calculate the diameter of the round ventilation duct:

![]()

here:D - diameter of the ventilation pipe, m.

If it is necessary to calculate the diameter of the ventilation pipe of rectangular cross section, its indicators are selected based on the obtained cross-sectional area of the round pipe.

Calculation of the area of ventilation elements

The calculation of the ventilation area is necessary when the elements are made of sheet metal and it is necessary to determine the quantity and cost of the material.

The area of ventilation is calculated by electronic calculators or special programs, many of which can be found on the Internet.

We will give several tabular values of the most popular ventilation elements.

| Diameter mm | Length m | |||

| 1 | 1,5 | 2 | 2,5 | |

| 100 | 0,3 | 0,5 | 0,6 | 0,8 |

| 125 | 0,4 | 0,6 | 0,8 | 1 |

| 160 | 0,5 | 0,8 | 1 | 1,3 |

| 200 | 0,6 | 0,9 | 1,3 | 1,6 |

| 250 | 0,8 | 1,2 | 1,6 | 2 |

| 280 | 0,9 | 1,3 | 1,8 | 2,2 |

| 315 | 1 | 1,5 | 2 | 2,5 |

table 2. The area of direct round ducts.

The value of the area in sq. M. at the intersection of horizontal and vertical stitches.

| Diameter mm | Angle | ||||

| 15 | 30 | 45 | 60 | 90 | |

| 100 | 0,04 | 0,05 | 0,06 | 0,06 | 0,08 |

| 125 | 0,05 | 0,06 | 0,08 | 0,09 | 0,12 |

| 160 | 0,07 | 0,09 | 0,11 | 0,13 | 0,18 |

| 200 | 0,1 | 0,13 | 0,16 | 0,19 | 0,26 |

| 250 | 0,13 | 0,18 | 0,23 | 0,28 | 0,39 |

| 280 | 0,15 | 0,22 | 0,28 | 0,35 | 0,47 |

| 315 | 0,18 | 0,26 | 0,34 | 0,42 | 0,59 |

Table 3. Calculation of the area of branches and semi-branches of circular cross-section.

Calculation of diffusers and gratings

Diffusers are used to supply or remove air from the room. The cleanliness and air temperature in each corner of the room depend on the correct calculation of the number and location of ventilation diffusers. If you install more diffusers, the pressure in the system will increase, and the speed will drop.

The number of ventilation diffusers is calculated as follows:

N=R\(2820 * v * D * D),

hereR - throughput, in cubic meters \ hour,v - air speed, m \ s,D - diameter of one diffuser in meters.

The number of ventilation grilles can be calculated by the formula:

N=R\(3600 * v * S),

hereR - air consumption in cubic meters \ hour,v - air velocity in the system, m \ s,S - cross-sectional area of one lattice, sq.m.

Channel heater calculation

The calculation of the electric type ventilation heater is as follows:

P=v * 0,36 * ∆T

herev - the volume of air passed through the heater in cubic meters / hour,∆T - the difference between the temperature of the air outside and inside, which must be provided to the heater.

This indicator varies between 10 - 20, the exact figure is set by the client.

The calculation of the heater for ventilation begins with the calculation of the frontal cross-sectional area:

Af =R * p\3600 * Vp,

hereR - the volume of the intake flow, cubic meters \ h,p - density of atmospheric air, kg \ cubic meter,Vp - mass air velocity at the site.

The cross-sectional size is necessary to determine the dimensions of the ventilation heater. If, according to the calculation, the cross-sectional area is too large, it is necessary to consider the option from the cascade of heat exchangers with the total design area.

The mass velocity index is determined through the frontal area of the heat exchangers:

Vp=R * p\3600 * Af.fact

For further calculation of the ventilation heater, we determine the amount of heat needed to warm the air flow:

Q=0,278 * W * c (TP-Ty)

hereW - consumption of warm air, kg \ hour,Tp - supply air temperature, degrees Celsius,Tu - street air temperature, degrees Celsius,c - specific heat of air, a constant value of 1.005.

Since in the supply systems the fans are located in front of the heat exchanger, we calculate the flow of warm air as follows:

W=R * p

When calculating the ventilation heater, you should determine the heating surface:

APN = 1.2Q\k(Ts.t-Ts.v)

herek - coefficient of return of heat by the heat exchanger,Ts.t - the average temperature of the coolant, in degrees Celsius,Ts.v - the average temperature of the inflow,1,2 - cooling coefficient.

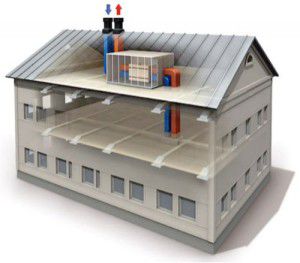

Displacement ventilation calculation

When displacing ventilation in the room, the calculated ascending air flows in places of increased heat generation are equipped. Cool, clean air is supplied from below, which gradually rises and is removed to the top of the room along with excess heat or moisture.

With proper calculation, displacing ventilation is much more efficient than mixing in rooms of the following types:

- halls for visitors in public catering establishments;

- conference rooms;

- any halls with high ceilings;

- student audiences.

Calculated ventilation displaces less efficiently if:

- ceilings below 2m 30 cm;

- the main problem of the room is increased heat generation;

- it is necessary to lower the temperature in rooms with low ceilings;

- powerful air swirls in the hall;

- the temperature of harmful substances is lower than the temperature of the indoor air.

Displacing ventilation is calculated based on the fact that the heat load on the room is 65 - 70 W \ sq.m, at a flow rate of up to 50 liters per cubic meter of air per hour. When the heat load is higher and the flow rate is lower, it is necessary to organize a mixing system combined with cooling from above.

The video will tell you about a compact air handling unit operating on the principle of displacement: