The modern market provides a wide range of ventilation equipment, diverse in characteristics and prices. We will help you make the right choice by introducing you to the main types, manufacturers, and reveal the secrets of manufacturing, installation and repair.

A set of ventilation equipment for mounting the system depends on the characteristics of the facility.

The following factors influence the choice of equipment:

- the purpose of the object;

- number of floors;

- the presence of hazardous emissions in the air;

- building configuration;

- scope of use;

- the presence or absence of a service area.

For example, in pools, air needs to be drained, and in other cases, on the contrary, moistened.

Ventilation Equipment Manufacturers

Today, Russia supplies ventilation equipment to all major global manufacturers, each specializing in its own segment.

Household and semi-industrial equipment

Such systems provide air exchange of up to 6 thousand cubic meters of air per hour. They are installed at facilities no more than 650 square meters. meters.

Among others, foreign manufacturers of ventilation equipment, such as: Remak (Czech Republic) Kanalfakt / systemair (Sweden) Ostberg (Sweden), Ventrex (Europe). Russian manufacturers of ventilation equipment Korf and Arctos produce reliable, competitive products.

Monoblock installations are a separate category. This is a complete system assembled in a single module with sound insulation. Monoblock systems are characterized by a large spread in prices (within 50%) compared to typesetting. Their firms produce SHUFT, Electrolux, Aeroblock other.

Industrial and special purpose

Industrial ventilation equipment serves an area of more than 400 square meters. meters, providing air exchange of 4 thousand cubic meters per hour. Special purpose systems are installed in buildings with increased requirements for microclimate (operating rooms, production of drugs and electronic equipment), as well as in smoke removal systems and emergency air exchange.

Equipment of this class is supplied only on request.

The most famous and large foreign manufacturers of ventilation equipment: Wesper, Pyrox, Lennox, Clivet, VTS Clima, Remak. The largest Russian manufacturers of industrial-grade ventilation equipment: Moven, Veza, Arktos. The characteristics of special-purpose vehicles are very specific, so it is selected only for a specific object.

Types of ventilation equipment

Depending on the project, domestic and industrial ventilation equipment can be exhaust, supply or supply and exhaust. The exhaust installation can function separately from the supply or they are combined by an automatic control center. Such complex schemes are used at large facilities: in shopping, sports and entertainment centers, industrial enterprises.

Conventionally, all manufactured ventilation equipment by power can be divided into three segments:

- semi-industrial and domestic;

- industrial;

- "Special" purpose.

Ventilation equipment for a home or enterprise is also divided by functionality:

- for air supply;

- to control the air supply;

- for processing (filtration, drainage, heating, humidification or cooling) of air;

- to control the system.

The most common types of ventilation equipment for homes, offices and industrial facilities:

- condensing unit;

- air heaters (can be electric or water);

- air coolers (water or freon);

- fans

- recuperators;

- silencers;

- air curtains;

- modules for aspiration and air disinfection.

Air exhaust equipment is structurally simpler. The "heart" of the exhaust system is a duct fan. Silencer and filters are installed in most cases.

During the construction of the supply system, the air must be heated and cooled; additionally, appropriate modules are installed.

The main components of the ventilation system

- Ventilation grilles. Through them, air enters from the street into the room. They protect the system from dust, rain, insects. Sometimes, instead of an external grille, a supply valve is installed;

- Check Valve protects the system from unauthorized entry of street air. In the cold season, this indispensable function helps to keep the room warm. As a rule, the valves have an electric actuator that opens them when the fan starts;

- Filters purify street air of fluff, dust and flies. Standard coarse filter with particles less than 10 microns. For special requirements for supply air, finer filters with fine particles are used;

- Channel heaters used in cold weather to heat the supply air. There are water and electric modifications. The former are preferred for large objects. Operated at a temperature of -40 ... + 40 degrees. They differ in thermal power. A more modern way of heating air is with a recuperator. To warm clean air, it uses dirty heat, without affecting their chemical composition. The lack of recuperators in their high cost;

- Fan This is one of the main components of the air exchange system.

When selecting a fan, pay attention to performance and design pressure.

Fans can be:

- radial - create high pressure in the system;

- axial - differ in low pressure at high productivity, therefore they are bad in systems with many turns, branches.

Duct fans are designed for installation directly in the lumen of the ducts.

- Silencers suppress the aerodynamic hum in the system using sound-absorbing materials. They wrap the walls of ventilation ducts, fans. Sound attenuators also reduce the noise level propagating through the air ducts;

- Air ducts - highways through which air flows through all stages of preparation for the serviced premises. They can be of various shapes, sizes, stiffnesses. Equipped with shaped parts for the formation of turns, branches;

- Distributors - are installed directly at the entrance to the served premises. They direct jets or streams of air in the right direction and with the right intensity. Types of valves: diffusers, grilles. In addition to the main task, they also perform decorative;

- Regulation and automation systems. Cabinet or control panel. It can be mechanical or electronic, depending on the complexity of the system.

Types of industrial equipment

- Central air conditioners it is a type of non-autonomous air exchange system that serves one or more large rooms through a network of ducts. Each room supports unique microclimate parameters.Air cooling and heating is carried out using water, electricity or steam. The air is filtered and brought to the required humidity;

- Supply units and mini supply units filter the air, bring to the required temperature, mix and deliver to the room;

- Modular compact installations contain blocks for filtering, cooling, heating and mixing air. They work at an ambient temperature of -40 ... + 40 degrees;

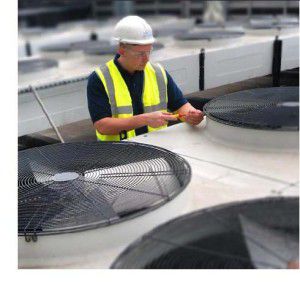

- Roof fans used for outflow of air in buildings for various purposes. They withstand the temperature of the environment from -30 to +40 degrees, are installed outside (on the roof) of the building exclusively in a horizontal position. Mounting on a sloping roof is possible.

Fans are not intended for transporting air with explosive, aggressive and abrasive inclusions.

Ventilation equipment manufacturing

Ventilation equipment manufacturing is a high-tech process that requires the use of precise and sophisticated equipment. The best companies have a full production cycle and their own design bureaus, which are engaged in the development of new products and the introduction of new technologies.

In the manufacture of ventilation equipment, rather expensive machines are used. For example, the minimum cost of a machine for manufacturing a spiral-wound duct is 50 thousand euros. And this is the easiest and cheapest component of ventilation.

New machines and competent employees will ensure a minimum of defective products and waste with high productivity.

It is beneficial to have your own storage facilities for finished products and for material. After all, purchasing large quantities of metal, you can get a good discount from the supplier.

Video on the production of certain types of ventilation equipment:

Installation and installation of ventilation equipment

Installation of ventilation equipment is carried out in several stages:

- Study of the features of the building;

- Drawing up the terms of reference;

- Project creation;

- Conducting preparatory work;

- Installation of air ducts;

- Installation of ventilation equipment;

- Connection to electric and other engineering networks if necessary;

- Commissioning activities;

- Commissioning.

A designer, builder, or ordinary buyer may require a certificate for ventilation equipment.

The certificate confirms the compliance of the technical parameters with the requirements of SNiP and Gosstandart. Certified ventilation equipment removes liability from the builder in the event of an accident.

Ventilation equipment is certified on the basis of regulatory acts of Gosstroy and Gosstandart. Safety certificates are issued only in the State Standard of the Russian Federation.

To obtain a certificate of fire and sanitary safety, you must first obtain an opinion from the relevant authorities. Only organizations accredited by the Main Directorate of the State Fire Fighting Service of the Ministry of Internal Affairs are entitled to issue such certificates.

The efficiency of the future system largely depends on the proper installation of ventilation equipment. Therefore, you should not save on the services of professionals. As a rule, suppliers of ventilation equipment offer their specialists for installation work.

Ventilation equipment maintenance

Maintenance of ventilation equipment, entrusted to experienced professionals, ensures long-term trouble-free operation. In addition, quality maintenance is one of the conditions for well-being of people.Indeed, with illiterate cleaning and the lack of disinfection, after a while, the ventilation unit becomes a hotbed of microbes and toxins.

Maintenance of ventilation equipment includes:

- diagnostics;

- cleaning external and internal components;

- replacement parts if necessary;

- system disinfection;

- execution of an act of work performed.

Sometimes a minor repair of ventilation equipment is included in the service package. All events, as well as the timing of maintenance of ventilation equipment are specified in a written agreement between the service company and the customer.

The price of work depends on the diameter and length of the ducts. As a bonus, the customer can provide free diagnostics and execution of the conclusion.

Repair of ventilation equipment

Repair of ventilation equipment can be standard or overhaul.

The list of works during a typical repair of ventilation equipment includes:

- sealing rusted places, dents, holes of ventilation ducts and cases;

- repair of fasteners of any type (soldering, riveting, flanges, nipples), sealing fasteners with bolts with the replacement of worn parts;

- repair of shaped elements with adjustment of the position and cross-section of deflectors and distributors;

- repair of ventilation chambers;

- straightening of fan blades;

- repair and balancing of the shaft and rotor;

- installation of new bearings to replace worn ones;

- filter change, oil change, lubrication, cleaning;

- repair of heater tubes;

- lubrication of all parts and mechanisms;

- elimination of signs of corrosion, painting;

- reduction of equipment vibration and reduction of hum.

Overhaul of ventilation equipment for an enterprise, a house includes all routine repair procedures and additionally:

- replacement of fan rotor and shaft;

- installation of new rolling bearings without fail;

- rotor balancing on special equipment;

- restoration of thermal insulation, valves, chamber doors;

- replacement of a third or more ducts and fittings;

- painting the whole system;

- commissioning works.

The owners of apartments or cottages with ventilation are usually engaged in the repair of ventilation on their own. We strongly advise against taking unjustified risks, as well as resorting to the services of unverified craftsmen “by announcement on the fence”.