The design of ventilation systems allows you to plan the amount of work and upcoming costs at the initial stage. According to the specification of the equipment, an estimate is made for the construction of the facility. Despite the fact that the design of ventilation of industrial premises or private houses is quite expensive, without it the construction of a large building is impossible.

The apartment ventilation project is ideally created at the design stage of the building itself or the planning of major repairs. Then it is possible to optimally distribute the equipment, integrate it into existing engineering communications, and neatly fit into the interior design.

The design of supply and exhaust ventilation takes place in several stages:

- Calculation of equipment and communications. It is made on the basis of room parameters and microclimate requirements.

- Drawing up wiring diagrams.

- Drawing up the final draft.

Work is carried out after the conclusion of the contract for the design of ventilation with an exact indication of the deadlines and cost.

At the conclusion of the contract, the customer can be provided with samples of technical specifications for the design of ventilation or ready-made projects for review.

There are standard apartment ventilation projects that can be used for installation and significantly save money.

Terms of Reference for Ventilation Design

To compile a technical task it is not enough to know only the basics of ventilation design. The task indicates the microclimate parameters, the method of air exchange, data on the coolant.

Drawing up the terms of reference for the supply ventilation project is preceded by an analysis of the layout and purpose of the building. Therefore, the designer must provide the most complete data:

- the purpose of the object;

- location (including relative to parts of the world);

- properties of building materials;

- glazing area and number of doors;

- floor plans and sections;

- information about the coolant.

When designing industrial ventilation, you need to delve into the intricacies of the process, as well as the work schedule (for industrial facilities). The technical requirements take into account the special wishes of the customer.

Calculation of the ventilation project

When designing the supply and exhaust ventilation, calculations are made for the best from a technological and economic point of view, the selection of equipment, the shape of the route and the parameters of the ducts.

The calculation of the microclimate in the premises is carried out for cold, transitional and warm seasons. Environmental parameters are determined by SNiP 23-01-99 and 41-01-2003.

The calculation of air exchange is determined on the basis of the frequency of air exchange approved in the regulatory documentation. When determining the rate of air exchange, heat inflows and the number of people constantly in the premises are taken into account.

Multiplicity of air exchange for rooms, depending on the purpose

| Apartment, private house | 4-8 |

| Office | 4-8 |

| Kitchen | 15-30 |

| Entertainment Center | 4-6 |

| Score | 3-8 |

| Server | 6-10 |

| Pool | 5-6 |

| A restaurant | 7-12 |

The volume of air supplied per 1 person in cubic meters / hour

| Apartment, private house | 25-60 |

| Office | 35-60 |

| A restaurant | 45-60 |

| Kitchen | 65-90 |

| Entertainment Center | 35-60 |

| Score | 25-60 |

| Pool, sports complex | 80 |

The type of air exchange is selected taking into account the purpose and architecture of the room, the ability to organize natural air exchange.

Depending on this, the system is selected:

- supply;

- supply and exhaust;

- exhaust;

- local

- general exchange;

- natural;

- mechanical.

The equipment is selected depending on the purpose of ventilation, building architecture, economic benefits and types of coolant. A standard selection scheme or an individual one can be used if the standard one is not suitable for technological or economic reasons.

Standard equipment selection schemes

- When designing the ventilation of an apartment, small shop or office, natural ventilation is usually provided, reinforced in kitchens and toilets with exhaust fans. Air supply is supported by compact inflow units or ventilators. It is also advisable to install ducted air conditioners or supply and exhaust systems;

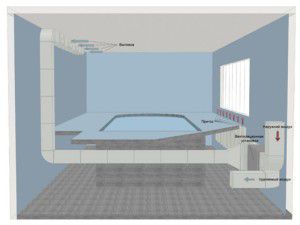

-

When designing the exhaust ventilation of a pool or sauna, supply and exhaust systems are provided in combination with a dehumidifier. Some compact ventilation units are also equipped with dehumidifiers;

- When designing the ventilation system of a cafe or restaurant, two installations are laid down at once: general exchange and local. For a small cafe, a compact ventilation system is enough. Large catering enterprises are equipped with powerful hoods for kitchens and stacked blow-in units for the dining area;

- Designing the supply and exhaust ventilation of the sports complex provides for intensive air exchange with the possibility of conditioning;

- The ventilation of high-rise buildings, shopping and entertainment complexes, public buildings is carried out by central, roof and autonomous air conditioners, chiller-fan coils;

- Design of industrial ventilation should implement more complex and specific tasks. Therefore, equipment is selected for each object individually. As a rule, if the technological process is accompanied by abundant evolution of heat and toxic fumes, local and general exchange exhaust systems are combined. As local devices, suction, oases and air showers are used. When designing ventilation of industrial premises with abundant emission of dust, explosive and toxic substances, aspiration systems are provided.

Air preparation during ventilation design

During the design of ventilation of a private house, shop or factory, the need for filtering the supply, and often the removed air, is taken into account.

Classification of filters for general premises

| Filter group | Class | Efficiency | Notes |

| Preliminary (G) | 1 | Up to 65% | The action is calculated by suspension with large particles (from 2 micrometers) |

| 2 | 65-80% | ||

| 3 | 80-90% | ||

| 4 | More than 90% | ||

| Fine cleaning (F) | 5 | 40-60% | The action is calculated by suspended particles up to 1 micrometer |

| 6 | 60-80% | ||

| 7 | 80-90% | ||

| 8 | 90-95% | ||

| 9 | More than 95% |

Air distribution for ventilation design

There are two possible ways to distribute air:

- crowding out;

- mixing.

In addition, the best way to inflow air and remove it is determined:

- upper;

- lower.

Type of tributary:

- flat jets;

- flooring jets;

- fan;

- compact.

The number of air distributors and their type are calculated.

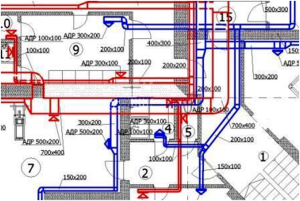

Airway Parameters

The cross section and shape of the ducts are calculated, the material for them, the shape, the number of branches and turns, pressure loss, and sound pressure at the entrance to the room are determined.

These indicators are directly related to the power of the equipment, the parameters of silencers. And all together determines the price of the ventilation system.

Smoke ventilation design

The task of the anti-smoke ventilation unit is to block and limit the spread of smoke.In each fire compartment, an autonomous smoke system is mounted. Designing smoke ventilation significantly increases the cost and complicates the system. It is necessary to buy additional equipment, as many materials widely used in ventilation (for example, PVC air ducts) do not withstand the temperature.

The draft smoke exhaust ventilation involves the use of only special fans and ventilation ducts that do not deform at high temperatures, fire dampers and smoke detectors.

Sometimes doors of a special design and smoke screens are installed.

As a rule, smoke ventilation is designed by computer programs. The program carries out all the necessary calculations, simulating the situations that occur during a fire. The designers carry out the rest of the work “manually”.

The calculation is made for each room separately, taking into account the leaks of ventilation ducts, fire valves, the area of the smoke channel. To accelerate the evacuation of smoke in long corridors, several smoke detectors are designed. The exact number of them depends on the area of the room.

For a direct corridor with a length of not more than 45 meters, 1 receiver is enough. If there are corners, 1 device is installed for every 30 meters. Limited sections of the corridor should not exceed 20 meters in length.

Since the development of a fire situation is simulated by a computer, it is impossible to verify the accuracy and correctness of calculations. Therefore, the installation of the airway and smoke exhaust channels requires the experience and qualification of the designer. Smoke ventilation is not used for air intake. It only removes smoke without connecting to a common air exchange system. The smoke removal system only starts during a fire. The rest of the time it is periodically checked for performance.

In a one-story private house it is allowed to design smoke control ventilation with natural draft.

Standard conventions are used in the design of smoke exhaust ventilation.

Cleanroom ventilation design

The main difference between the design of cleanrooms and other premises for the need to use HEPA filters H11-H14. HEPA filters create high resistance at the beginning of use - up to 350 Pascals, and at the end before replacing up to 650 Pascals. This feature must be taken into account when calculating air flow rates. Filter resistance should be compensated.

Classification of filters for special purposes

| Filter group | Class | Efficiency | Note |

| High Efficiency (N - HEPA) | 10 | 85% | The efficiency of the filter is calculated by the presence of dust with particles 0.1 - 0.5 micrometers in size. |

| 11 | 95% | ||

| 12 | 99,5% | ||

| 13 | 99,95% | ||

| 14 | 99,995% | ||

| Ultra High Performance (U) Filters | 15 | 99,9995% | |

| 16 | 99,99995% | ||

| 17 | 99,999995% |

When designing the ventilation of clean rooms, the main attention is paid to:

- increased tightness of fences;

- the device of the vestibule gateway;

- selection of HEPA filters.

In clean rooms, the pressure should be excessive. If its value is exceeded, a decrease in tightness is possible due to deformation of the fences. Therefore, the pressure should be strictly controlled.

When the vestibule lock is opened, the overpressure decreases and can level off with the surrounding rooms. Then dust can enter the room through the doors.

When designing the ventilation of clean rooms, air exchange is often expressed through air mobility, which should be from 0.35 to 0.51 meters per second.

The air domain should be within 30-60 times, sometimes with a moderate degree of purity it is allowed to reduce the value to 20 times. An error of 20% is permitted.

Maximum speed is necessary with high activity of employees and the presence of dust-generating equipment.If there is not much personnel in the room, the work is sedentary, and the equipment does not emit dust, minimum speed values are sufficient.

Air movement in clean rooms

After cleaning in special filters, air enters the premises with virtually no dust.

The air supply in this case performs two tasks:

- Reducing the concentration of dust that appears in the room during the presence of personnel and equipment.

- Evacuation of this dust from the room.

There are 3 types of air movement in the rooms:

- Unidirectional ordered or laminar. Air jets move in the same direction parallel to each other.

- Disordered or turbulent. Air jets do not move parallel to each other.

- Mixed. In the part of the hall, laminar is organized, and in the other, turbulent.

Cleanroom projects include only unidirectional ordered air movement systems. For this, air is supplied through filters placed over the entire surface of the ceiling. The floor is made a perforated and exhaust chamber under it. Between the exhaust chamber and the filters are air ducts for air recirculation.

According to the basics of ventilation design, when the width of the clean room is less than 5 meters, it makes sense to design exhaust grilles instead of a raised floor at the bottom of the wall. Vertically, the air moves to a height of 0.5 above the floor and then turns to the grilles.

In clean rooms, medium mode often organize turbulent air movement. HEPA filters are placed on the ceiling, in general, the flow is directed downward, but the individual jets are not parallel to each other.

Mixed air circulation is possible only if technological processes are combined in one hall with increased and normal requirements for the dust content in the air. For zoning the premises in a special way, filters are mounted on the ceiling. There are more filters in the “clean” zones, less in the usual ones.

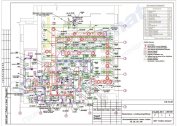

Wiring diagram for ventilation design

The graphic wiring diagram of the ventilation system contains not only the drawing itself, but also a description of the type of ventilation, equipment parameters and its location, specification of equipment and materials.

Together with the scheme, the project of the ventilation system is accompanied by a task for construction work on the preparation of sites for equipment and duct routes. A feasibility study is being prepared.

When creating a project for industrial or household ventilation, equipment is placed in convenient service areas.

The final stage of ventilation design

The final draft of the ventilation of the production room is handed over to the customer only after the complete installation of the equipment.

According to the contract, the ventilation project contains:

- symbols of materials and equipment;

- exact sizes and bindings;

- intersections, junctions and forks;

- placements of equipment with axonometry;

- calculations with explanations;

- specifications;

- the main drawing of the system and drawings of additional subsystems, power supply, ventilation wiring, drainage, communications between modules, cooling circuits;

- executive wiring diagram.

During the design of exhaust ventilation, at each stage, coordination with designers, architects and other specialists who carry out the finishing, construction and installation of engineering systems is carried out.

Ventilation design deadlines

The design period of ventilation is on average from 15 working days for the smallest buildings and is determined by the area of the object. With an area of up to 300 square meters, the ventilation project is carried out in a minimum period.

With an area of up to 1000 square meters, the design of ventilation of the supply or supply and exhaust type takes up to 40 days.

The project ventilation period of the facility is more than 2 thousand square meters. meters is determined individually.

Any design work, whether it is designing the ventilation of a private house or the shops of a confectionery factory, must be carried out by a qualified licensed specialist.

You will receive answers to the most common questions about ventilation design from the videos: