To remove contaminated air from the premises, it is necessary to provide a ventilation system at the design stage. An understanding of the principle of operation and a competent choice of equipment is a necessary condition for creating an effective system of any type, especially for general ventilation.

Purpose of general ventilation

General ventilation is a system that, unlike local ventilation, provides air circulation in the entire volume, in all rooms. It is designed in such a way that there are no "dead zones".

It is used in such cases:

- indoor air is heavily polluted with dust, toxins;

- high humidity;

- stuffy, constantly lacking fresh air;

- substances with a pungent or unpleasant odor are stored / used;

- high risk of mold;

- the humidity level is very different at different times of the year;

- Condensation constantly forms on the glass.

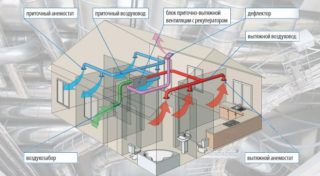

All these problems general ventilation allows solving. With severe air pollution, exhaust ventilation is installed. If the air is not very polluted, but not enough oxygen, install a general exchange supply system. Most often, supply and exhaust elements are used, which ensure the removal of contaminated air masses and the influx of fresh air. The system, if necessary, is supplemented by filters and heaters.

Types of systems and main characteristics

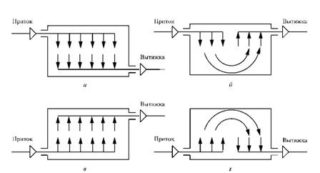

Varieties of general ventilation in the direction of air movement are distinguished:

- supply;

- exhaust;

- mixed.

By the method of moving air masses, natural and forced ventilation are distinguished. In the latter, the process is carried out thanks to the operation of the fans.

Supply ventilation of the general exchange type allows you to normalize the microclimate in the room, ensuring a constant flow of fresh air. The concentration of contaminants is reduced to a minimum level, even if initially it was very high. Exhaust is responsible for the removal of contaminated and heated air. With the help of fans, air masses are removed outside the building. General exchange of supply and exhaust ventilation is the most effective system, since it combines the properties of both supply and exhaust.

The system of mechanical general exchange type uses ventilation equipment for the forced movement of air masses: duct, axial, roof, centrifugal fans. The use of specialized devices makes it possible to heat and purify air, makes ventilation independent of weather conditions and wind. The main disadvantages: financial costs for the payment of electricity and repairs, noise at work.

Natural ventilation is designed in such a way that the air masses move in the right direction due to natural draft. Advantages: low cost, since no electrical equipment is used, easy installation, no noise and, despite the absence of fans, acceptable performance. Disadvantages: air purification and heating are not provided, it is impossible to increase the ventilation rate.

The efficiency of the system operating on the principle of natural traction is attractive, but in practice any external influence significantly changes the efficiency not for the better, therefore it is preferable to install a mixed version: with forced air injection inside the premises.Due to the influx of air masses, excess pressure is created. Due to this, the contaminants are forced out through the cracks, doors, windows.

Airflow calculation

At the design stage of general ventilation, thorough calculations are required. Any errors lead to a violation of the air balance and microclimate, the appearance of unpleasant odors, dusting.

In large areas, the use of automated systems is relevant. Automation maintains the required air exchange rate - the ratio of the volume of incoming air masses to the total air volume. Setting up an automated system must be done by professionals - this is a complex process that requires maximum accuracy.

The sequence of calculations in the design of general ventilation:

- Determine the type of ventilation system.

- Find out the number of people constantly present in the room.

- Take into account the degree of air pollution and the nature of harmful impurities in it. This will allow you to choose the right equipment for air purification to a safe level.

At the rate of 30 m3 / h per person, forced general ventilation is planned. If the system is a natural type, the productivity per person is 60 m3 / h.

Exhaust ventilation is calculated without taking into account the degree of air pollution using a simple formulaP = A * Bwhere

- A - air volume per person;

- B - the number of people in the room.

If air is contaminated, the formula appliesP = Aat / (Ko - Kp)where

- ANDat - weight of harmful substances in mg delivered in one hour;

- Ko - concentration of toxins in the air;

- Kp - the level of pollution of the supply air masses.

Influx performance is calculated using a different formulaL = Aat / (U - Up)where

- L - desired volume;

- ANDat - weight of toxins delivered per hour in mg;

- U - specific concentration of harmful substances in m3 / h;

- Up - toxins in the supply air masses in m3 / h.

If the project of general ventilation is compiled for a small house, it is enough to perform approximate calculations using a simple formula. More complex calculations for buildings with a large number of rooms should be made by professional designers.

Equipment and materials

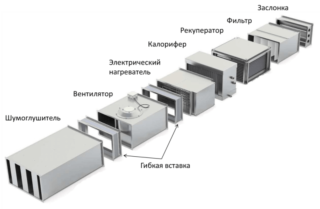

When designing the ventilation system of general exchange type, which is the most effective, in country houses, the hood is usually organized where moisture and intense odors are formed - in the bathroom, kitchen, toilet. Supply valves are often installed in the bedroom and living room. Supply valves should be equipped with filters and heating devices, because in the cold season clean, but cold air will enter the room. Installation of a complex general exchange ventilation system is not complete without the following types of equipment:

- valves

- cleaning devices;

- air coolers and heaters;

- recuperators;

- fans

- ventilation grilles;

- air flow distributors;

- electronic control and management devices;

- silencers.

Recuperators are installed in order to save. They transfer the thermal energy of the heated air removed from the room to the supply cold air.

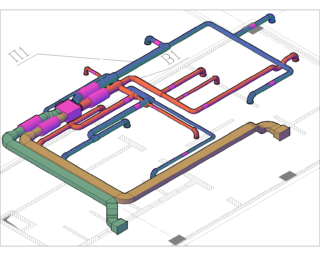

General ventilation scheme

It is impossible to achieve the efficiency of general ventilation without designing and calculating. The project should take into account all the details regarding compliance with fire safety standards, sanitary standards. Mandatory attention is paid to architectural features, a scheme is drawn up. The more rooms in the building, the more difficult the project will be.

First, it is necessary to perform calculations regarding the volume of the supply and exhaust air flow.Then determine the types and quantity of equipment, materials, fasteners. Choose the installation method and make an estimate for each stage.

General ventilation is more efficient than local ventilation, but more difficult for independent design and installation, so you should take up the organization of such a system yourself only in the case of small objects. Complex projects must be carried out by professionals, taking into account the norms of SNiP, otherwise there is a high probability of a waste of finance and the creation of an inefficient system.