Ventilation ducts in a private house or high-rise building are necessary for the outflow of exhaust air and fresh air. The air exchange system is designed and constructed in accordance with the requirements SNiP 2.04.05-86 and SNiP 2.08.01-89. The basis for the maintenance, inspection and cleaning of ventilation ducts are the standards for the operation of the housing stock.

Types of ventilation ducts

All types of ventilation ducts differ in the following indicators:

- Sectional shape:

- rectangular;

- round.

- Production Material:

- PVC, plastic;

- brick;

- concrete;

- metal.

- Configurations:

- tough;

- flexible.

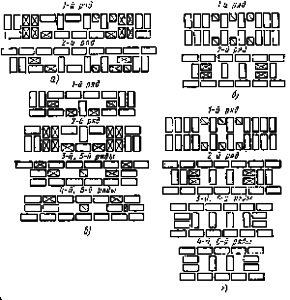

In apartment buildings with natural air exchange, ventilation ducts are equipped with special rectangular concrete blocks. The ventilation ducts in private houses with stove heating are made of masonry.

Brickwork Rules for Ventilation Ducts

In the manufacture of ventilation ducts in a private house or high-rise building:

- only solid brick is used;

- standard section diameter 140 x 140 mm. If the ventilation duct is adjacent to the chimney, a ½ brick wall is made between them;

- so that the masonry is smooth and not clogged during the construction process, use the technique of inventory buoys (an empty plywood box is inserted into the trunk, which is moved as the mine is being erected);

- The masonry from the inside should be as smooth as possible, since any irregularities worsen traction;

- To lay out inclined segments, apply a brick hewn at the necessary angle.

With gas or steam heating, PVC or metal types of ventilation ducts are suitable.

Smooth types of ventilation ducts, for example, pipes made of PVC or galvanized steel of circular cross section, provide the least resistance.

Flexible ducts are often installed on small sections with many turns and forced air exchange. The ribbed inner surface creates a strong resistance to air flow and reduces aerodynamic properties.

The buoy height should be 8 to 10 rows.

Air Duct Requirements

The requirements for ventilation ducts apply to all types, regardless of the materials and type of system:

- Ventilation ducts are being constructed in accordance with the design and building codes;

- When designing, the need for periodic inspections of ventilation ducts and their cleaning is taken into account. As well as fire safety rules;

- From heated buildings, air is vented by natural ventilation;

- The ventilation grilles on the channels must always be open;

- The laying of ventilation ducts should be smooth, without protrusions and bulges, the direction of the ducts is vertical;

- When replacing rectangular ventilation ducts with round ones, the cross-sectional area is selected equal to or greater than the original;

- The thickness of the brickwork of the ventilation duct made of brick without cavities is from 12 cm. The internal walls of the ventilation duct are not plastered, excess mortar is removed by squeezing;

- The ventilation ducts of private houses are allowed to be combined with one riser with chimneys.

The requirements for ventilation ducts are taken into account during the construction and operation of the building.

Checking the ventilation ducts and its frequency

Checking the condition of the ventilation ducts is carried out by the employees of Rospotrebnadzor. In residential buildings, this is the responsibility of the management company. The verification plan is agreed with the sanitary services.

The first check of the state of ventilation ducts is assigned when the building is commissioned.

The frequency of inspections of ventilation ducts in multi-storey buildings is once every 12 months, and in rooms with gas appliances once every 6 months. In rooms with special requirements for the state of the air environment (children's and medical, catering) - once every 6 months.

A method of unscheduled inspections of ventilation ducts has been developed, which is used when there are bases.

The check determines the need for repair, cleaning and disinfection of ventilation ducts.

When checking ventilation ducts in apartment buildings, pay attention to:

- the thickness of the walls of the ventilation duct from brickwork;

- compliance of the material with the requirements of SNiP;

- correspondence of the section to the project;

- quality of thermal insulation;

- the height of the head above the roof level, its condition;

- the presence of protection from rain and snow;

- the presence of traction;

- compliance of the volume of exhaust air with standards.

During checks of the condition of the ventilation ducts of apartment buildings, special attention is paid to the condition of the walls. Deposits of dust, debris, cobwebs, blockages are detected.

All results are recorded in inspection reports in duplicate. A period of 14 to 30 days is given for the elimination of comments.

Channel Survey Technique

According to the method of checking ventilation ducts, all measurements are carried out at a temperature difference of 13 degrees in the street and in the building.

To check the draft in the ventilation duct, attach a sheet of tissue paper to the ventilation grill. If traction is sufficient, the sheet is held on the grate by itself.

The air velocity in the ventilation duct is measured with an anemometer. Having determined it and knowing the parameters of the duct, it is possible to calculate the amount of air passed by the system.

Inspection of masonry ventilation ducts is carried out using a camera, camcorder or stereo tube. The stereo tube is inserted into the ventilation duct, the bulb is turned on and the image is fed into the eyepiece through a system of mirrors.

The most advanced device for periodically checking ventilation ducts is a photo-acoustic video camera. It records and archives the received data. The visual verification method allows you to determine the need for cleaning the ventilation duct, the place of destruction, unauthorized alteration of the ventilation shaft by residents.

Cleaning the ventilation ducts

You can clean yourself only the part of the ventilation duct adjacent to the apartment.

What is necessary:

- screwdriver;

- a brush or a broom on a long handle;

- a vacuum cleaner;

- respirator and cotton gloves.

Before you start cleaning the ventilation ducts in your apartment, wear a respirator and protective gloves. When removing the grill, be careful! Insects and even rodents can live in the ventilation duct.

Progress:

- carefully remove the ventilation grill;

- broom the accessible part of the ventilation pipe;

- Vacuum dust;

- thoroughly rinse the ventilation grill and mesh, put them in place.

Unfortunately, cleaning the apartment ventilation ducts rarely brings visible results. And only specialists can remove rubbish from the whole mine.

Residents are strictly forbidden to independently examine and clean the house ventilation!

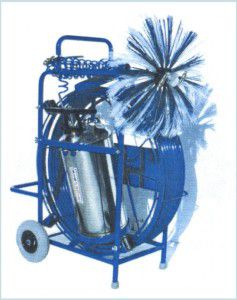

Standard cleaning of ventilation ducts is carried out by brush mechanisms with brushes of suitable diameter. Sometimes special vacuum cleaners are used. If the ventilation ducts are large in diameter, people in protective suits and masks can descend into them on climbing equipment.They disassemble the rubble in the mines, remove large debris and stones, clean the walls.

The cost of professional services depends on the amount of work and the complexity of access to the ventilation shaft. In some cases, this even requires the construction of scaffolding.

Video about the company working to clean the ventilation ducts: