During the combustion of natural gas, oxides of carbon, nitrogen, sulfur, formaldehydes are released. Accumulating in the air, they cause lethargy, dizziness, lacrimation and the development of serious diseases. In addition, household gas combustion products are explosive. Therefore, any room with gas equipment must be equipped with ventilation.

Ventilation is the key to safe and efficient equipment

Not only is people's health ventilated in a kitchen with a gas stove or boiler.

High-quality gas combustion requires oxygen. With its deficiency, a lot of carbon monoxide and unoxidized substances are released into the air during combustion. You can notice this by the yellow color of the flame, high with abundant soot.

The efficiency of gas equipment is reduced - the fuel burns out as much, but less heat is generated.

Natural gas itself is even more dangerous, which can enter the room air, for example, if a draft blows out a fire on a burner, the gas supply hose to the stove has dried up, and the gas boiler has broken.

The choice of gas ventilation system in a private house or apartment depends on the type of boiler and the characteristics of the boiler room.

Ventilation requirements for a gas boiler room

The ventilation requirements for a room with a gas boiler or a kitchen with a stove are similar.

Gas boilers with a closed combustion chamber are equipped with a coaxial ventilation channel, through which air is simultaneously supplied from the street to the burner and combustion products are discharged.

Installation of ventilation in a room with a gas boiler should be carried out taking into account technological requirements and standards:

- No more than 2 units of gas equipment are connected to the chimney, regardless of their remoteness and level of location;

- Combustion products must enter the chimney at a distance of at least 50 cm at different levels;

- If the supply is carried out from one level, a cut with a height of 50 cm is installed in the chimney;

- The ventilation system for a gas boiler in a private house must be absolutely tight. Minimal leakage of carbon monoxide and soot, potentially dangerous to human life, is not allowed;

- Seams at the joints of the chimneys are treated with a sealant resistant to high temperatures;

- To prevent fire, all components of the system are provided with thermal insulation;

- Ventilation is provided based on: outflow in the amount of three-time air exchange, supply in the amount of outflow plus the volume of combustion air.

Ventilation device with a gas boiler

The following types of ventilation for a gas boiler in a private house exist:

- Natural and mechanical according to the principle of traction;

- Exhaust, supply and combined as intended;

- Channel and channelless by design.

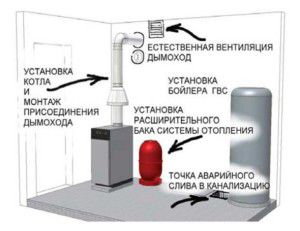

When equipping a room with a gas boiler with an open combustion chamber, the following is taken into account:

- In a room with a gas boiler, a ventilation chimney is equipped to divert carbon monoxide to the street;

- A general exhaust ventilation system is installed from a room with a gas boiler;

- Supply ventilation is provided in the boiler room for a gas boiler, supplying fresh air and oxygen from the street.

As a supply ventilation for a room with a gas boiler, slots in windows and doors, gaps through which air can enter the room are quite suitable. This is especially true of private houses, where a separate room is allocated for the boiler.

If the room closes tightly, a special system and forced ventilation for a gas boiler are required.

When choosing equipment, the boiler power should be taken into account, otherwise the cost of installing gas ventilation will not justify itself. The oxygen supply must be sufficient to maintain a normal flame. Otherwise, soot builds up on the heat exchanger, and the heat output decreases. If the air supply is not provided in the room with the gas boiler, the atmosphere is discharged in it. The oxygen level decreases, reverse draft may appear, that is, the combustion products will be pulled into the room. A situation is dangerous when the boiler is installed in the kitchen. Absorbing oxygen, it will cause oxygen starvation in people: pain in the eyes, headache, malaise.

When calculating the flow of air, take into account the volume of the room in which the boiler is installed.

Air movement principle

With mechanical traction, air is driven by a fan. It is located in the ventilation grill at the entrance of the duct into the room. With natural draft, air moves due to the difference in pressure on the street and indoors. And even if there is good natural traction, installing a small exhaust fan that will support the movement of air is not out of place.

If you equip a mechanical air supply, then increased pressure is created in the room and the exhaust air is pushed out through the air duct.

Exhaust ventilation works by forced removal of exhaust air.

There is another type of ventilation of the gas boiler - supply and exhaust or combined. In this case, this is a combination of the previously described systems.

Duct or ductless ventilation

Channelless ventilation for a gas boiler in a private house is a hole in the ceiling or walls. Holes connect adjacent rooms. For example, a hole is made between the bathroom and the toilet, and a ventilation duct is led out of the toilet.

Duct ventilation of a room with a gas boiler is a complex system of ventilation pipes conducted around the house. This type is most relevant for wet and dusty rooms.

The cross-section of the pipes and their location should be calculated by a specialist.

Installation of ventilation in a room with a gas boiler

Making the kitchen ventilation system with a gas stove or boiler is not so difficult. Any owner with a basic set of tools and some skills can handle this.

Exhaust ventilation

For a device for exhaust ventilation of a gas boiler, you will need:

- a fan (preferably with a check valve so that air does not penetrate into the apartment or house);

- ventilation grill;

- PVC air duct suitable for the diameter of the fan.

Progress:

- Mark with a circle the place where the hole for the duct will be. Make the diameter of the circle a little larger;

- Using a puncher, drill holes in small increments in a circle and one in the middle;

- Carefully, with a hammer and a chisel, knock out the middle and get a round hole into which the pipe is inserted;

- Close the cracks between the pipe and the wall with foam or mortar;

- Install an exhaust fan;

- The last step is to attach a ventilation grill that will give the structure a finished look and protect the housing from insects and debris.

Forced ventilation

When supplying gas ventilation equipment in a private house, several important rules should be considered.

The basis of the system is a supply unit. It receives air from the street, filters, cools or warms and delivers into the room.For an apartment or a residential building, low-power household equipment is suitable. The main advantage of such ventilation is quiet operation and ensuring complete comfort indoors.

The simplest variant of the supply unit is the supply fan. It is installed according to the above scheme.

Geyser ventilation

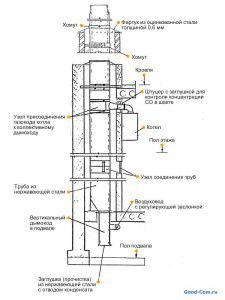

The main ventilation requirement for a geyser is the presence of a chimney. It is made of metal corrugated pipe, steel or coaxial pipe. The most effective is considered to be a coaxial chimney, so this option for ventilation of a gas column is in great demand. This is a reliable system that has been running smoothly for many years without failures and malfunctions. Features of the chimney depend on the power of the gas column.

Any chimney for a column includes:

- protective umbrella (crowns the design);

- the pipe itself (made with or without thermal insulation);

- a passage pipe separates the pipe from the wall of the house;

- brackets;

- clamps are installed on the joints of pipe sections;

- pipe to column adapter;

- inspection window to check the condition of the chimney;

- condensate tank.

It is important that throughout the chimney its inner diameter is the same, the parameters are indicated in the instructions for the column. The total length of the chimney from 4 meters. It is important to take into account climatic conditions, in a cold climate it is preferable to insulate the chimney. When installing ventilation in a private house for a gas boiler or column, the end of the chimney is discharged 1 m above the roof.

Gas Chimney Requirements

-

The chimney must be performed taking into account all the requirements of SNiP;

- An own chimney must be connected to the gas column;

- Smoke exhaust must be ensured, otherwise gas leaks may occur;

- The material for the chimney must be resistant to moisture and temperature;

- The chimney must be rigidly and firmly fixed to the wall, without sagging;

- The main thing that needs to be achieved when installing ventilation for a geyser is uniform traction. It is easiest to achieve it using smooth pipes with a circular cross section;

- The main indicator for choosing the diameter of the chimney is the size of the inlet;

- The chimney is installed vertically, which provides excellent traction;

- In the lower part of the chimney, a revision hatch is equipped, while condensate is discharged through it.

Installation of a chimney for a geyser

- The passage pipe is installed in the wall, a 90-degree turn is attached to it from the outside. The column itself is attached from the inside;

- Outside, a chimney pipe is installed. This is done sequentially, one pipe from bottom to top. Joints are strengthened with clamps;

- Evenly distribute the fasteners along the length of the pipe and fasten them to the wall. The optimum distance between the fasteners is 2 m. The pipe should not bend;

- At the top we install an umbrella, and at the very bottom of the pipe there is a viewing window;

- At the end of the installation, we check the traction. We bring a lit match to the chimney. If the flame slopes into the pipe, the work is done efficiently.

Kitchen ventilation with gas stove

Natural ventilation for gas stoves, equipped in all apartment buildings and private houses, most often does not fulfill its purpose. The reasons are incorrect design, builder mistakes, lack of maintenance and cleaning. The simplest test is whether ventilation works in the kitchen with a gas stove: smoke a cigarette indoors and return to it after 15 - 20 minutes. The strong smell of smoke? This means that the requirements for ventilation of a kitchen with a gas stove are not fulfilled and it is time to improve the system.

Ventilation requirements for a kitchen with a gas stove

To ensure sufficient air exchange, a room with a gas stove must meet the following requirements for ventilation of a kitchen with a gas stove SNiP 42-01:

- Ceiling height over 2 m 20 cm;

- The presence of a ventilation duct or window with an open window in the upper part;

- Under the door or in its lower part, a slot or hole with a total area of 25 square meters. cm.

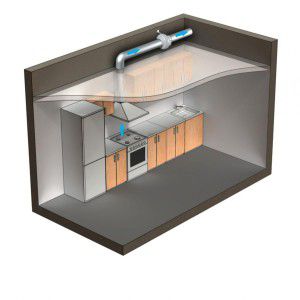

Air outflow

The most common way to normalize ventilation over a gas stove is to install a hood. The fan will draw air rising above the hob, food odors and carbon monoxide. A wide hood hood will direct the fumes directly into the duct. Thus, the hood provides forced exhaust ventilation of the kitchen with a gas stove. The cost of the hood varies widely and depends on the power, additional functions, design and manufacturer.

There are two types of hoods:

- with filtration and air recirculation;

- with exhaust air to the outside.

Hoods of the first type can not be called part of the ventilation system, because they do not participate in the air exchange. But the second fully ensure the outflow of exhaust air. In the place of which fresh is being dragged from the street. But if plastic windows are installed in the kitchen with a gas stove, fresh air ventilation requires additional measures.

The hood power is selected by the formula:

M = O * 10

ABOUT - the amount of air in the kitchen, calculated as follows:

O =H * L * S

H - room height,L - the length of the room,S - the width of the room.

According to regulatory documents, it is allowed to equip mechanical ventilation for a gas boiler of an inflow-blowing system in residential apartments of multi-apartment buildings, without disrupting the operation of the general house ventilation. That is, it is impossible to remove the exhaust duct into the shaft, completely blocking the ventilation grill. Otherwise, when the hood is off, the ventilation in the room of the gas boiler or kitchen will not function.

The problem is solved with the help of a special ventilation grill with an outlet for a round duct.

All the secrets to connecting the hood in the video:

Air supply

The supply of fresh air necessary for the normal operation of gas equipment and the well-being of people is carried out by supply devices.

The following types of supply devices for ventilation of a gas stove in a private house or apartment are presented on the market:

- Window supply valve. It is built in the casement of a plastic window, it works automatically or in manual mode. It is prone to icing in especially severe frosts;

- Wall inlet valve. Installation requires a hole in the outer wall. There are models with air filtration, can be automatic;

- Ventilator. It is hung on the lower shutter of a plastic door, works from a network. Not only filters the supply air, but also warms it.

Any of the listed devices for forced ventilation of the kitchen with a gas stove or boiler can be installed independently using our recommendations.